RUNNING, UPKEEP AND OVERHAUL

Page 69

If you've noticed an error in this article please click here to report it so we can fix it.

Interesting Contributions ircm Maintenance Engineers, Drivers and Mechanics.

Removing a Spigot Bearing.

T1ROM " G.P.," of Bristol, we have received the following description of a very ingenious tool he hag made with which, he tells us, he can extract the races of the roller bearings of the constant-drive pinion of his A.E.C. 416 and 426 types of 'vehicle. Without this tool he had always to remove the gearbox to renew these hearings, but by means of it he has been able to draw them after merely dismantling the Spicer joint at the rear and removing the four screws on the gearbox rear-end cover ;' by sliding hack the main shaft he can proceed to extract the races.

An Accompanying sketch shows the device, which 'somewhat resembles the ordinary wheel puller, but the legs have booked ends, so that by tightening the

screw they are first opened' out so that the hooks engage with the race, then' the sliding piece abuts 'au. the end of the shaft so that further.rotatien results in the: withdrawal of the race. .

The drawings 'ESUitain no very new points.which'WOull diStinguish the tool from the ordinary, wheel puller, but being *alter arid' mOte compact it can be used'in the small area Of a gearbox.

An Unusual Carburetter Defect.

A GLAMORGANSHIRE reader, " G.T.P.," of Porth, was called out to repair a lorry stranded with engine trouble of a mysterious nature.

He turned the starting handle and the engine fired, only to stop at once with a report in the silencer: After this nothing would induce the engine to run. The Ignition and induction system were found to be in order. When the driver was cranking the engine, our correspondent was leaning over a wing working on the carburetter. He noticed that there was no sucking sou'nd from the air inlet such as is usually heard. He promptly dismantled the carburetter and found that the small setscrew. which holds the throttle butterfly to its spindle, had disappeared. This meant that the throttle was uncontrollable. Not having a suitable screw to replace the missing one, a split pin was emideyed temporarily. This experience is related for the benefit of those who might be faced with a similar difficulty in the future, . An Aid to Refacing Cone Clutches.

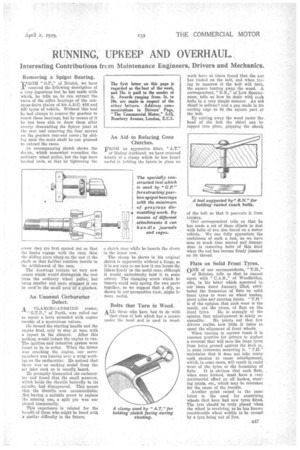

FROM an apprentice fitter, 'AT." of Bishop Auckland, we have reeeived details of a clamp which he has found useful in holding the fabric in place on a clutch cone while he inserts the rivets in the inner row.

' The clamp he shows in his original sketch is apparently without a hinge, so it is not:easy to see how it can locate the fabric firmly on the metal cone, although it would undoubtedly hold it to some extent. The clamping screw which he inserts could only spring the two parts together, so we suggest that a clip, as shown in our perspective view, might be more useful.

Bolts that Turn in Wood.

ILL those who have had to do with that class of bolt which has a square under the head and is used in wood

work have at times found that the nut has rusted on the bolt, and when trying to unscrew it the bolt will turn, the square tearing away the wood. A. correspoudent, "R.N.," of Low Spennymoor, tells us how he deals with such bolts in a very simple manner. An old chisel is softened and a gap made in its cutting edge to fit the square part of the bolt.

By cutting away the wood under the , head of the bolt the chisel can be tapped into place, gripping the shank of the bolt so that it prevents it from

turning. ••Our correspondent tells us that he has made a set of these chisels to deal with bolts of any size found on a motor vehicle. We can fully appreciate the usefulness of such a tool, as we have seen so much time wasted and damage done in removing bolts of this kind when the nut has become firmly jammed on its thread.

Flats on Solid Front Tyres.

ONE of our correspondents, "TM.," of Brixton, tells us that he cannot agree with C.A.B.," of Woodbridge, who, in his letter which appeared in issue ssue dated January 220, attributed the formation of fiats on solid front tyres to wear on wheel bushes, pivot axles and steering joints. " T.H." is of the opinion that such wear is the result, not the cause, of flats on the front tyres. He is strongly of the opinion that misalignment is solely re

sponsible. He points out that few drivers realize how little it takes to upset the alignment of front wheels.

When turning in narrow roads it is common practice for drivers to neglect a reversal that will save the front tyres from being ground against the kerb or, in some instances, mounting it. " PH." maintains that it does not take many such strains to cause misalignment, which, in some cases, will result in rapid wear of the tyres or the formation of flats. It is obvious that such flats, when once formed, must have a very detrimental effect on all bushes, steering joints, ete., which may be mistaken . for the cause of the trouble.

Another point raised in the same letter is the need for examining wheels that have had new tyres fitted. The tyre should be truly placed -vhen the wheel is revolving as he has known considerable wheel wobble to be caused by a tyre being out of line.