A Dual-purpose SIX-WHEELED TRAILER

Page 57

Page 58

If you've noticed an error in this article please click here to report it so we can fix it.

IT is particularly interesting to observe the wide variety of purposes for which the trailer is now being employed, and especially those types which have been built to meet the individual requirements of users. Carriers of this type have already been constructed to transport loads up to 85 tons.

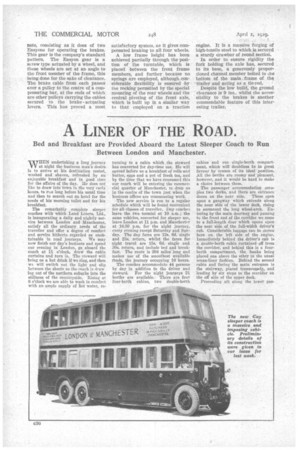

The model which we illustrate is a six-wheeler designed to carry the Insley excavator from one field of operation to another. The actual machine weighs only 12 tons, but the trailer itself is designed for a load of 20 tons and is so arranged that, by superimposing a platform, boilers and other machinery up to this weight can easily be transported. The user is W. E. Chivers and Sons, Ltd., of Devizes.

The trailer frame is 12 ft. 1 in. long and 8 ft. 7 ins. wide. It is comprised entirely of rolled channel steel of 9-in. by 3i-in. section. Six longitudinal members run the full length and, at their ends, are cross-members running the full breadth. Two smaller crossmembers are positioned inside the frame. Protruding to the extent of some It ft. 0 ins., beyond the front of the frame, are two further longitudinal members which are superimposed along the whole length of the frame ; .these take the front axle.

The four rear vdheels are held in two carriages orcradles which are allowed to pivot vertically, each being mounted on an axle passing through its centre, thus allowing for any unevenness in the surface which has to be negotiated.

same section of channel steel is again used in these cradles, which are stiffened at their centres by massive castings accommodating the main axles. The wheels are carried on Timken roller bearings of one standard size, and the wheels are all of the same diameter and equipped with three solid tyres

apiece.

The excavator is a chain-track =Chine. Therefore, it was necessary only to provide platforms for these tracks at each side of the trailer, the material used being 2i-in. oak laid across the frame. At the rear are two hinged ramps of channel steel and oak.

The braking system employed on this trailer is worthy of particular note, consisting as it does of two Easyons for operating the brakes. This gear is the company's standard pattern. The Easyon gear is a screw type actuated by a wheel, and these wheels are set at an angle to the front member of the frame, this being done for the sake of clearance. The brake cable from each passes ever a pulley to the centre of a compensating bar, at the ends of which are other pulleys carrying the cables secured to the brake actuating levers. This has proved a most satisfactory system, as it gives compensated braking to all four wheels. A low frame height has been achieved partially through the position of the turntable, which is placed between the front frame members, and further because no springs are employed, although considerable flexibility is ensured -by the rocking permitted by the special mounting of the rear wheels and the central pivoting of the front axle, which is built up in a similar way to that employed on a traction engine. It is a massive forging of high-tensile steel to which is-secured a sturdy drawbar of round section. In order to ensure rigidity the fork holding the axle has, secured to its base, a generously proportioned channel member bolted to Lite bottom of the main frame of the trailer and acting as a tie-rod.

Despite the low build, the ground clearance is 9 kW., whilst the accessibility to the brakes is another commendable feature of this interesting trailer.