The UNCONVENTIONAL in

Page 50

Page 51

If you've noticed an error in this article please click here to report it so we can fix it.

RADIATOR DESIGN

rpHE commencement of this _L article has to be made by an assertion of fact—quite contrary to the belief of most readers of this journal—that the modern type of tubular radiator is hardly efficient. It is so, because only the front row of tubes acts effectively ; the second row helps a little, the third is much less useful, and the fourth and fifth are practically inoperative. It should be realized, too, that this diminution in effectiveness is much more than is represented by the relative position of these tubes in the ranks.

Some Reasons Why the Ordinary Form of Radiator is Inefficient.

There are two principal reasons for this inefficiency. The first is the more obvious and might occur to anyone. It is this: The front row of tubes gets the benefit of the fresh, cool air; the second row only meets that air after most of its cooling capacity has been given to the first row; the third row is much worse off in that respect than the second, and the fourth and, still more, the fifth are cooled to a minor degree. That is one reason for the inefficiency of the tubular radiator which is generally employed at the present time.

The other reason for the incompetence of the radiator with several rows of tubes is that a multitude of closely situated tubes arranged row behind row, with the second rank opposite the narrow spaces of the first, the ,tubes of the third opposite the spaces in the second, c28 and so on, as is the customary arrangement, resists the flow of air, thus-reducing the volume passing through to the engine, on which current the efficiency of the cooling so much depends.

A Quasi-scientific Explanation.

We can put these reasons in another way. It is a fundamental law of the transference of heat that it varies in proportion to the difference in temperature at the contacting surfaces between which the transference is being effected. 'We are concerned with the transference of heat from the hot circulating water to the cool, or presumably cool, air, and the important factor therefore, according to the above law, is the difference in temperature between that of the water and the air, or, more precisely, between that of the outer surface of the tubes through which the water is passing and the air. So far as the front row of tubes is concerned the difference may be great; the water may be boiling, or nearly so, and in the winter the air may be a temperature at which water freezes. The speed of transference of heat is, therefore, likely to be at a maximum. By the time the air reaches the fifth row of tubes it is practically as warm as the surface of the tubes themselves and the cooling effect is practically negligible.

The other fundamental law is that the speed of transference of heat depaids also upon the quantity of cold air which can be brought into contact with the surface of the tubes in a given time. The more air that can be induced to flow past the faces of the tubes the better the cooling effect. If, therefore, there be so many rows of tubes that the air has a difficulty in passing through the radiator, the cooling effect, even of the front row, is reduced accordingly.

The way in which manufacturer:4 have endeavoured to increase the efficiency of a radiator, in the second respect, is apparent in the modern designs of radiator for commercial vehicles, the radiators being built eitherwith a mass of plain copper tubes, closely spaced, so as to offer as much surface as possible to the air, or they are constructed with rows of tubes all fitted with gills, thus increasing the available surface per tube and reducing the number of tubes necessary.

High Radiation Efficiency With Small Frontal Areas

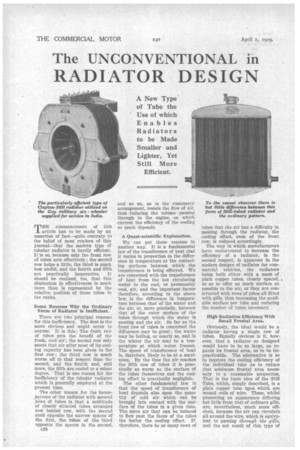

Obviously, the ideal would be a radiator having a single row of tubes. Equally obvious is it, however, that a radiator so designed would have to be so large, as regards its frontal area, as to be impracticable. The alternative is so to improve the cooling efficiency of the individual tube as to reduce that minimum frontal area necessary to a ' reasonable proportion. That is the basic idea of the Still Tube, which, simply described, is a plain copper tube upon which are wound coils of wire. These, whilst presenting an appearance differing but little from that of ordinary gills. are, nevertheless, much more efficient, because the air can circulate all around the wire, which is equivalent to passing through the gilts, and the net result of this type of

construction is one end which designers have in view, namely, to enable a maximum volume of air to be brought into contact with the cooling surfaces of the wire and tube and to perform this operation in a minimum 'of time.

With this improved tube it is altnoSt possible. to make a radiator of convenient size and having only one row : of tubes. The makers of the tube, however, have discovered an easy method of • getting practically the same result. The tubes are so arranged as to give the equivalent of a single row and are thus operating at their maxim-mu efficiency, in the twin senses that. they are always in -contact with fresh, cool air and they present a minimum of resistance to the pas. sage of currents. The fan draws a maximum volume of air past the tubes and through the gills, thus establishing a maximum efficiency in the two directions which I have shown to be so important.

The way in which this efficient arrangement of tubes is achieved is made apparent by one of the accompanying illustrations. They are merely set in zig-zag fashion, so that no tube is behind another. The arrangement should be compared with the orthodox plan as shown on another illustration.

The tabulated figures, showing a comparison between an ordinary gilled-tube radiator and one of equivalent cooling capacity as fitted to a well-known and popular type of 5-ton commercial vehicle, are of interest. Particular attention should he directed to the figure for the number ,,of tubes—one row of 20 displaces five totalling 158—and to the last line, showing that the total weight of the radiator, incTuding 'water, is 143.4 lb., as against 91.68 lb., a saving of 51.72 lb., which is equivalent to 36 per cent.

The foregoing figures show very clearly the marked advantages possessed by this form of tube, and it is important to note that similar modifications can be effected in practically any gilled-type radiator. Another of the illustrations shows the appearance of a radiator as fitted to a Guy motor vehicle and equipped with the Still Tubes, arranged in the manner described in the foregoing paragraphs.

Where exceptionally ardubus conditions of service are to be tilet, as arose in connection with a, design of a vehicle for the War Department to operate in hot climates, special types of radiator embodying this tube have been used with satisfactory results. Such a radiator, is shown in another illustration. When a complete vehicle is seen fitted with this radiator it will be noticed how comparatively small it is, notwithstanding the fact that its cooling effect is so much more efficient, so as to be capable of performing Its functions satisfactorily under exceptionally severe conditions of service.

This reduction of radiator area is Important for passenger vehicle work, as it enables the width to be kept small.

The maker of Clayton-Still radiators is the Clayton-Dewandre Co., Ltd., Titanic Works, Lincoln.