Mobile Servicing Units of the R.A.F.

Page 24

Page 25

If you've noticed an error in this article please click here to report it so we can fix it.

Special Roadvehicle Maintenance Workshops Which are Responsible for Keeping as Many as31000 Machines in Serviceable

Cnndition

AN army, proverbially, marches on its stomach, but that an air force depends upon its road wheels is not so apparent. For four long years the Royal Air Force, based in this country, has remained a static organization dependent upon road transport only for maintaining supplies of machines, munitions and materials. The creation of tactical air forces to move up in support of offensive operation by Continental armies has altered that picture entirely.

The preservation of lengthening lines of communication has brought fresh' demands upon the road transport belonging to the air seryices, and upon the units deputed to keep that transport on the road. Special M.T. servicing sections have been operating for some time now, and recently we visited an R.A.F. light-repair unit, which had been established under active service conditions and which is completely mobile.

In a war of movement everything goes forward on -wheels.. The unit under review serves a combined H.Q.

a medium-bomber group and econ naissance wing. It is representative DE many other similar units, spread throughout the R.A.F. Such a unit would have to be responsible for the Maintenance, in roadworthy condition, of some 3,000 vehicles of all types. It caters for quick repairs, top overhauls and general servicing. Major overhauls and complete stripping-down jobs are dealt with by heavy-repair depots. The test is whether the work nec:essary on an unserviceable vehicle can be done in three days in the light-repair unit.

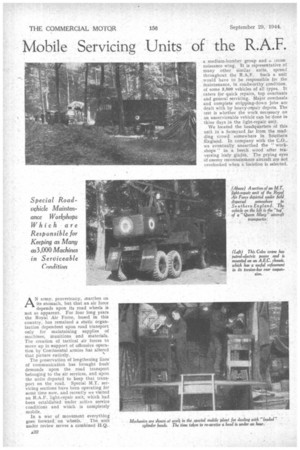

We located the headquarters of this unit in a farmyard far from the madding crowd somewhere in Southern England. In company with the C.O., we eventually unearthed the " workshops " in a beech wood after traversing leafy glades. The prying eyes of enemy reconnaissance aircraft are not overlooked when a location is selected. The first mobile workshop to which we were introduced was right up to date, for two mechanics were busy attending to the cylinder heads of a six-cylindered engine which had been giving trouble as the result of running on 80 octane leaded fuel. A head can be dealt with in 40 niinu tes.

This fueltrouble s tackled in a practical manner for. on looking around the " shop," we noticed among other equipment Sioux and Black and Decker valve facers, and home-made extractors. One cunning 'gadget was a valve thickness-and-angle-gauge, which showed a tell-tale light and so prevented valve reconditioning being carried to the danger limit of thinness. A • discuasion with the engineer officers disclosed their opinion that these current valve problems will rapidly disappear when British motor technicians and metallurgists have had as much experience with leaded fuels of high-octane value as -their American contemporaries.

Next we passed along to the standard mobile workshop, equipped, with machinetools and an air compressor driven by a 9 Kva. 230-volt electric motor. This took its current, ultimately, from a power tender equipped with a 12 h.p. Coventry-Climax engine, the generated current being delivered via a rectifier to a battery storage plant. All the, power and lighting for the unit originated from this tender. In passing, we inspected a mobile bath-van .fitted out with hot water delivered under pressure from a motor

pump and with a bathroom lined out in stainless steel.• Repairing motor vehicles is not exactly a clean affair under normal conditions, and the unit has every reason to study hygiene under the exacting conditions of mobile warfare.

Perhaps the most impressive piece of equipment possessed by this light-repair organization was the Wardew-France breakdown truck. This powerful piece of American mobile machinery is a veritable heavy workshop on wheels. It can perform an amazing variety of duties, up to the hauling out of a 50-ton Tank. In support of a nucleus of these massive machines were many Coles cranes on A.E.C. chassis.

This type has petrol-electric power, and torsion-bar suspension to the tandem rear wheels. Spares and stores were carried by Thornycroft lorries with dixor four-cylindered engines, and among lighter vehicles in the repair unit was a profusion of Chevrolet trticks and Ford V-8 Utility vans. Under repair we noticed Bedford tankers of 900 gallons capacity from the Tactical Air Force.

Recently, a Hawker Typhoon wing moved lock, stock and barrel 300 miles in a few days to keep pace with the armies advancing towards Germany. Some idea of the magnitude that this problem set road transport is gained from such an insight into the organization of an MT. light-repair unit of the R.A.F.