Oil Filtration by Electrostatic Means

Page 24

If you've noticed an error in this article please click here to report it so we can fix it.

Developed From Sturtevant Plant Produced for the Cleaning of Gases, This New Device Embodies a Particularly interesting Principle

FFICIENT filtration of used oil is .1....tparticularlyimportant in these days when economy is so essential. Old oil becomes blackened with carbon deposit, and reduced in viscosity by dilution (i.e., the absorption of unburnt fuel), whilst its lubricating properties are not only impaired in this way, but by the ingress of road grit and other microscopical particles, which eventually become deposited in it as a form of sludge Water is also sometimes present owing to condensation, and this ,may form the oil into a kind of emulsion. In addition, engine oil ,from compression-ignition engines is often thickened by finely divided carbon.

Some oils are also subject to oxidation, but, in the main, the true body of the oil; if it can be cleansed from extraneous matter, -retains almost to the full its original lubricating properties.

In this connection, a particularly interesting apparatus for filtration is produced by the Sturtevant Engineering Co., Ltd., 147, Queen Victoria Street, London, E,C.4. This is known as an electrostatic oil filter, and as it does not work on the screening principle, it cannot choke, whilst it is able to produce a clear oil free from all solid matter.

The unique principle.of this filter is that it employs high-tension voltage to effect separation of the solid from the liquid. Advantage has been taken of pioneer work carried o it with the electrostatic precipitation of dust and fumes in flue gas and air.

The principle of the process is that when a dust-laden gas is passed between two electrical poles, one being charged and the other maintained at earth potential, an ionisation effect is set up which results in the particles of solid matter being projected to the earthed pole, where they collect as a mass, leaving the carrier, i.e., the gas or air, to pass on free from these particles. When filtering oil, the dirty oil takes the place of the dust-laden air.

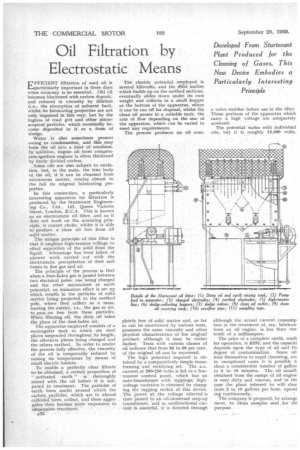

The apparatus employed consists of a rectangular tank in which are steel plates suspended throughout its length, the alternate plates being charged and the others earthed. In order to render the process fully effective, the viscosity of the oil is temporarily reduced by raising its temperature by means of small electric heaters.

To enable a perfectly clear filtrate to be obtained, a certain proportion of " activated earth" is thoroughly mixed with the oil before it is subjected to treatment. The particles of earth form nuclei around which the carbon. particles, which are in almost colloidal form, collect, and these aggregates then become ;more responsive to subsequent treatinent. -•-: • A22 The electric potential employed is several kilovolts, and the slid matter which builds up on the earthed sections, eventually slides down under its own weight and collects in a small hopper at the bottom of the apparatus, where it can be run off for disposal, whilst the clean oil passes to a suitable tank, the rate of flow depending on the size of the apparatus, which can be varied to meet any requirements.

The process produces an oil corn pletely free of solid matter and, so far as can be ascertained by various tests, possesses the same viscosity and other physical characteristics of the original product, although it may be rather darker. Tests with various classes of oil indicate that from 85 to 90 per cent. of the original oil can be recovered.

The high potential required is obtained by a comparatively simple transforming and rectifying set. The a.c. current at 200-250 volts is led to a lowtension control panel, which has an auto-transformer with tappings; highvoltage variation is obtained by changing the tapping switch of this device. The power at the voltage selected is then passed to an oil-immersed step-up transformer, 'and as unidirectional current is essential, it is directed through a valve rectifier before use in the filter. Those portions of the apparatus which carry a high voltage are adequately screened.

The potential varies with individual oils, but it is roughly 12,000 volts, although the actual current consump tion in the treatment of, say, lubricarc from an oil engine, is less than one tenth of a milliampere.

The price of a complete outfit, read3 for operation, is £275, and the capaciti depends upon the type of oil and du degree of contamination. Some oil lend themselves to rapid cleansing, ant in exceptional cases it is possible t4 clean a considerable number of gallon in 5 to 10 minutes. The, oil usual]] obtained from the sumps of oil engine is very dirty and viscous, and in thi case• the plant referred to will clew from -2 to 10 gallons per hour, operat ing continuously.

The company is prepared, by arrange ment, to clean samples sent . for thi purpose.