New Cowdrey Heavy-duty Brake

Page 127

If you've noticed an error in this article please click here to report it so we can fix it.

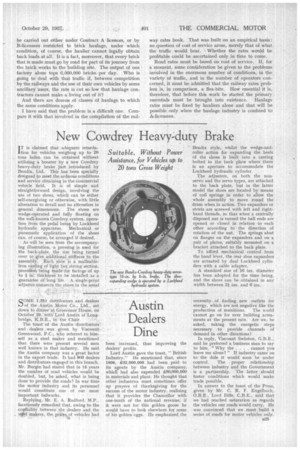

TT is claimed that adequate retardaItion for vehicles weighing up to 20 tons laden can be obtained without utilizing a booster by a new Cowdrey heavy-duty brake just introduced by Bendix, Ltd. This has been specially designed Co meet the arduous conditions and service obtaining in the commercial vehicle field, It is of simple and straightforward design, involving the use of two shoes, which can be either self-energizing or otherwise, with little alteration to detail and no alteration in general dimensions. The shoes are wedge-operated and fully floating on the well-known Cowdrey system, operation from the pedal being by Lockheed hydraulic apparatus. Mechanical or pneumatic application of the shoes can, of course, be arranged if desired.

As will be seen from the accompanying illustration, a pressing is used for the back-plate, the rim being turned over to give additional stiffness to the assembly. Each shoe is a malleable'iron casting of light but strong section, provialidi being inade,for facings of up to ft in thickneia•to be installed as a guarantee of -long life. A single-point adjuster connects the shoes in the usual

J3endix style, whilst the wedge-and

Power roller action for expanding the heels of the shoes is built into a casting bolted to the back plate where there is an aperture to accommodate the Lockheed hydraulic cylinder.

The adjusters, on both the non. servo and the servo types, are attached to the back plate, but in the latter model the shoes are located by means of 'coil springs in order to allow the whole assembly to move round the drum when in action. Two expanders or struts are screwed with left and righthand threads, so that when a centrally disposed nut is turned the ball ends are opened or closed in relation to each other according to the direction of rotation of the nut. The springs abut on flanges on the expanders and on a pair of plates, suitably mounted on a bracket attached to the back plate.

To afford mechanical control from the hand lever, the rear shoe expanders are actuated by dual Lockheed cylinders with a cable adapter.

A standard size of 16 ins. diameter has been adopted for the time being, and the shoes can be obtained in any width between 24 ins. and 6 ins.