Washing Tools and Appliances • for the Small User.

Page 73

Page 74

If you've noticed an error in this article please click here to report it so we can fix it.

It is well known that washing and cleaning are easier the Sooner they are done. If the job be left until the next morning the mud has had time to harden, and rain and mud spots, especially on heated surfaces such as the bonnet have had a chance to develop into permanent stains. The driver, if only one or two vans be kept, is often expected to keep his own vehicle clean. It is natural that he should prefer to wash and polish it in t h e morning, rather than when he is tired at night after the day's driving and the light, may be bad, especially during the winter months.

It is an advantage, therefore, if someone other than the driver can be employed to do the washing at night. The yard of the garage should be well drained and be preferably of concrete or stone setts, with facilities for good artificial lighting. For coupling up to the water supply, about 40 ft. of 1-in. rubber hose is required, fitted with a nozzle which allows for the variation of the jet. The washer should wear a pair of clogs and have two buckets, and the same number of sponges and chamois leathers if the panels he highly varnished and it be desired to retain their brilliance.

One bucket, sponge and leather can then be set aside for the more important parts of the work and for finishing off.

Brushes save time when mud has to be dislodged, but delicate paintwork is easily scratched by them. The best kind of brush is one which can be coupled up to the hoe so as to ensure that the Mud IS well softened before any attempt is made to remove it.

The best way a cleaning any vehicle is by the application of deah

cold water only. Water which is dried off after a reasonable interval does no harm to varnished paintwork ; in fact, it tends to harden and preserve a freshly varnished panel. As much mud as possible should be made to fall off by the repeated action of the stream of water. The sponge dipped in the bucket is used to moisten any hard spots, allowing time for the water to penetrate, after which the hose is again applied. The sponge should he continually rinsed in the bucket so as to ensure that all gritty particles are speedily removed.

The worst parts of the vehicle should be attacked first—that is, the underside of the wings, steps, wheels, springs and underwork generally, after which the main panels are 'washed, taking care to use a different sponge and leaving the bonnet until last so that it has a chance to dry. If there he any rain spots on the bonnet, these may be dried off by dabbing them with a clean leather pending the general washing of the bonnet.

The washing having been completed, the various parts are then dried with a leather, after which any good brand of body polish may he. applied, which will not only remove smears and add to the lustre of the paintwork, but will prevent much staining and spotting afterwards. The bright parts now receive attention, using such pastes or compounds as may be preferred, but using elbow-grease rather than a. generous supply of material from the tin to effect the desired result. The windows should be cleaned last with a damp chamois leather (particular care being taken to work well into any sharp corners) and then dried off with a cloth of non-fluffy material.

Washingon a Large Scale.

if more than a dozen vehicles have to be cleaned daily the garage should not only be large enough to house and maneeuvre

them into position, but there shouldbe sufficient room for dealing with repairs as well as a large washing space, all under cover. The small garage is often defective

in this respect, because, although there may be room for doing a few minor repairs, the van usually has to be taken out into an open ,yard for washing operations.

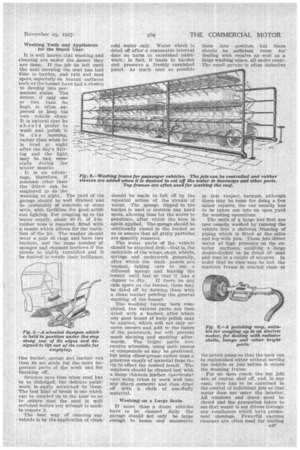

The units of a large bus fleet are now usually washed by running the vehicle into a skeleton framing of piping which is fitted at the sides and top with jets. 'These jets direct water at high pressure on the exterior surfaces, enabling •a :large double-decker to be freed of mud and dust in a couple of minutes. In order that no time may be lost, the washing frame is erected close to

the petrol pump so that the tank can be replenished either without moving the vehicle or just before it enters the washing frame.

For an ()lien coach the top jets are, of course, shut off, and, in any case, care has to be exercised in the control of individual jets se that water does not enter the interior. All windows and doors must be closed and the precaution taken to see that water is not driven through any ventilators which have permanent openings. Powerful vacuum cleaners are often used for dealing with the interior, and it is stated that the suction created is often sufficient to remove tickets from a wet floor.

Under a well-organized scheme, a large single-decked bus can be washed, cleaned and polished in , fifteen minutes, the longest part of the process being the polishing of the windows. If no washing frame be installed, some kind of moving platform becomes essential which can be adjusted for height, allowing the operator to work easily at any , level. Even when washing frames are installed, a certain amount of hand labour may be necessary to deal with those parts which are not readily attacked by the water jets.

Care of the Upholstery.

Seats which are upholstered in moquettemust be brushed if no vacuum-cleaning apparatus be available, the brushing being done, of course, before the floor is swept, Occasionally, the seats may be inspected for stains, which may be removed with soap and water, using the latter sparingly, or, if the blemish be obstinate, a .little benzine may be applied. Leather and leather-cloth seats should be gone over with a damp duster and finished with a dry one. In this way the dirt is collected effectively and scratching of the surface prevented. A little oliveor neatsfoot oil or leather reviver may be used new and then to keep the leather supple and to maintain its colour.

Any waterproof upholstery may be washed with soap and water if it be quickly dried afterwards. This will remove the grime which has become embedded in the surface and which is not removed by the vacuum cleaner. If any polished woodwork be used inside, it should be wiped occasionally with a rag moistened with linseed oil, the superfluous oil being wiped off with a dry duster. The hood of a. coach should always be kept extended when in the garage. It should be cleaned with a damp sponge and, when dry, should be well brushed both inside and out. Straps should be wax polished to prevent them from becoming brittle.

Window, Panel and Wing Repairs.

Complete standardization of the bodywork is rarely possible, because one type of vehicle is seldom the most economical for all classes of traffic, even in a small town, but assuming that it were possible, both chassis and body are continually being improved and new designs introduced, so that too much zeal for uniformity may easily result in not being up to date. The public-service vehicle proprietor, however, should always judge the merits of any bus and coach, not only from the point of view of the passenger's comfort, but also from the ease with which minor repairs may be effected. He, or his foreman, should visit the bodybuilder's factory and be shown the n48 easiest way of inserting a new glass and perhaps he may be able to judge between rival devices from this standpoint alone. He will naturally prefer to have as many windows as possible of the same size, so that he can keep one or two spares in stock ready cut to size and with polished edges. Any broken fixed windows of plain or fancy glass can be anticipated by keeping glass either .cut to size or of dimensions which allow for economical cutting.

Although, for a high-class bus or coach for private hire, large panel surfaces having no intervening moulding may be considered by many, to give a smart effect, yet the practical owner will prefer for service work that the panels shall be put on in sections and held at the edges by easily removed mouldings.

Wings, especially the front ones, often get dented and crumpled in service, so that if several vehicles have the same design of wings it is a good plan to keep a pair in. reserve. Small. dents may be removed by holding a dolly or other block of heavy material wrapped in a cloth over the damaged part and then hammering gently underneath. Wings should be painted black, because they are then easy to touch up after a repair, which

is not the case if any other colour be used. Although bumpers are growing rapidly in favour for private car use, they do not appear to be considered worth adopting by the bus owner, or, maybe, the licensing authorities have not yet expressed an opinion as to their merits.

Dampness.

On a wet day a good deal of moisture accumulates inside a bus, so that means should be provided for its ready escape. There should be holes in the floor at the sides, and the space between the inside and -outside panels should be ventilated by holes in the bottom side. It is also good practice not to make the inside casing boards continuous, but to leave gaps or slits above what may be termed the skirting board.

Lubrication and Inspection.

Window fittings should be inspected weekly and lubricated sparingly. If there be any mechanism below the waist this should be welt greased once a year, a matter which can generally be arranged with the coachbuilder during the annual overhaul. Door furniture, such as hinges, locks, dovetails, striking plates and buffers, should be examined and lubricated weekly. The pin of a butt hinge should be driven up about a quarter of an inch with a small punch in order" to oil it properly. Dovetails and striking plates should be adjustable, so that any looseness which may be set up' can be corrected by the turn of a screw. Body bolts should be examined for tightness once a week, whilst door-operating gear should be tested at the end of every day's work, as it is particularly important that this should work satisfactorily, especially in the case Of the whole operation of the bus being effected by the driver.