CLEAN LINES IN IASSIS DESIGN.

Page 58

Page 59

Page 60

Page 61

If you've noticed an error in this article please click here to report it so we can fix it.

The Modern Tendency Towards Refine' Productive of Complication. An Exai Induced a Qualified Writer to Discuss t Full Provision for All Requirei in Commercial Chassis Detail has been on of the Chassis at the Show has spective Advantages of Simplicity and in Driving and Maintenance.

A NYONE who, during the week, has made a sysilk.tematic tour of the many exhibits staged at the Commercial Motor Show cannot but help being impressed by the extreme divergence in chassis design of the vehicles exhibited there. It is, of course, understood that polish, nickel-plating, smooth paintwork and stove-enamel finish have their effect upon simple appearance; neverthelesS, if all illusion be discounted, the plain, straightforward chassis seems to be distinctly in the minority—a state of affairs which seems to indicate that no decision has yet been made as to whether it be preferable to have all parts readily accessible but external to the main features, or to enclose the whole of the " mechanism" and trust to really sound design to enable the parts concerned to be foolproof over a period of years.

It is realized, of course, that a clean chassis layout is not always easy to attain ; indeed, in certain special types of vehicle it is a very difficult matter to keep to elemental simplicity, especially when such items ss power-assisted brakes, centralized chassis lubrication and forward control are included in the specification. At the same time, it may be questioned whether everything possible is being done to attain the desired road performance and refinement in control, as simply and effectively as possible.

Lubrication of chassis parts (even if the various points be equipped with the modern type of nipple for use in conjunction with an oil-gun or a grease-gun), often requires the operator to crawl beneath the chassis in order to get at some of the more remote points requiring attention, but even supposing that pipe leads be taken to the outside of the chassis to enable the gun to be applied there, the question may fairly be asked: Is the system ideal? Against if might be mentioned the fact that each pipe must be fitted with at least two unions, and the number of points requiring attention might quite easily total to 50, thereby adding considerably to the possibility of failure and defeating any attempt at clean design.

Turning now to the power unit. There are two distinct schools of thought in the design of engines, one following the line that if all oil piping, water connections, mauifolding, etc., are external, any trouble can be detected and easily remedied, whilst the other side takes the view that an internal connection is less likely to give trouble than one that is external and that to make it integral with the main unit largely avoids any possibility of fracture or other troubles appertaining to joints and

connections. It is, of course, impossible here to say which course is to be preferred, but, from the average user's point of view it is certain that a simple layout has many attractions and, if all components be properly and sensibly arranged, maintenance work should be much lower than with the more complicated or external arrangement of components.

Broadly speaking there are two main divisions which can be made the subject for discussion—the chassis itself and the power unit, whilst there are still two further sub-divisions in each case. In the chassis lubrication of details forms one section, and the arrangement of controls, brakes, etc., the other. So far as power units are concerned, lubrication systems claim attention on the one hand, whilst, on the other, the question of the accessibility of the internal parts of the engine may quite well be ventilated.

We will first deal with the chassis. Perhaps the most outstanding examples of simplicity at Olympia are the latest types of Lancia and Saurer passenger chassis, both of which—despite the entire absence of pipes for lubrication purposes—seem to be reasonably easy to rook after. In both cases, too, the transmission and brake control rods appear to be the only external units other than the frame,' and, with all working parts enclosed, road grit, dust, water, etc., are excluded,

u32 Take the case of brake rods, for example. In most cases these components are now operated by swinging links from cross-shafts, which, of course, have to be lubricated in order to ensure the necessary freedom of movement. Without duplication of parts, there can very easily be upwards of six points requiring lubrication, merely to one or two cross-shafts grouped together with a compensating gear. It appears to be very easy to make the cross-shafts tubular, and having filled them with oil (with suitable leak holes arranged so that the various bearing surfaces can obtain an adequate, but not necessarily excessive, supply of lubricant), leave the arrangement to work automatically. No one yet seems to have hit upon the idea of incorporating the brake compensating mechanism in an extension of the gearbox casing, thereby allowing the whole of the working parts to operate in oil. Again, such items as the anchorage of both front and rear springs, the drag link and the track rod for the steering gear, etc., could quite easily be tubular (as they are now in many instances) and be loaded with oil for lubrication of the joints.

On one pleasure-car chassis, which is known to the could be lubricated almost perfectly by the oil slung up by the gears whilst ducts could be arranged to lubricate any additional but extraneous bearings; further, it should be quite permissible to run the brake rods into the rear-axle casing, which would enable the brakeoperating arms to be entirely enclosed within the case itself. In this way all rattle, rust and wear should be entirely eliminated and the sum total of attention required for the whole of the rear-axle unit would consist simply in replenishing the oil from time to time.

As at present arranged on the majority of chassis, brake adjustment is an extraordinarily difficult matter, involving the use of tools. It is all very well to say that the nuts on the ends of the brake pull rods are readily accessible, but in a number of instances really to be effective an inspection pit is a sine qua non. In a braking system incorporating a properly lubricated compensating gear the forward end of the rod emanating from the pedal and the lever appears to be the correct point from which adjustment should be effected, and in both instances provision can be made in the design for them to be readily accessible; a large wingnut seems to be indicated with a self-locking device under the head. In this way running adjustments are the matter of a rew moments only and do not necessitate the use of tools.

It is impossible to imagine a better opportunity than that provided by the Show for all keen users to make an examination of the various chassis, with the object of studying the requirements of maintenance. It is, of course, impossible to mention all the features in an article such as this, but we are, nevertheless, able to quote a few examples front which the idea may be gathered.

It must be admitted that the most outstanding examples of clean chassis layout emanate from overseas. This, of course, may be due to the con

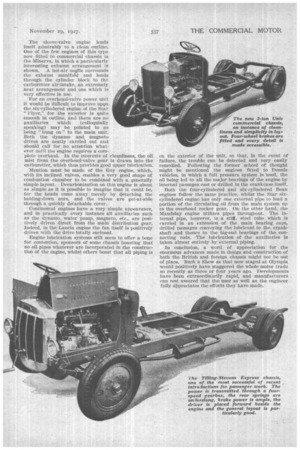

IN (Below) The new Lancia Omicron ar 1 passenger chassis—another instance I of clean exteriors and maximum of 1 accessibility. An interesting feature is the offsetting of the transmission ; line, which places the differential case to the side, where it would come 4 below the side seats of a bus or coach.

ditions prevailing in the country of their origin, where maintenance work generally cannot be relied upon to be so thoroughly carried out as it is here in England, whilst road surfaces generally may not be so good as those in this country.

Mention has already been made of the Lancia and Saurer chassis, and alongside these may also be placed the Unic 30-cwt. chassis, the Panhard-Levassor 2i-ton long chassis and the Minerva sleeve-valve-engined chassis, all of Continental origin. Nevertheless, there are several British vehicles which compare with the foregoing examples very favourably. The Bean, for instance, has the clutch and gearbox enclosed in a plain casting, whilst the brake gear is laid out on quite

simple lines and incorporates a simple adjustment. Thornycrofts have clearly made an effort to keep their chassis as free as possible from excrescences ; for example, two brake cross-shafts are lubricated from a single nipple in each side member, which, of course, obviates the necessity for lifting the floorboards when greasing up.

Another good example of a layout where lubrication points are reduced to a minimum is to be found in the W. and G. ambulance chassis. A Lockheed braking system is used, which, of course, cuts out all swinging levers, brake rods, etc., with their attendant points requiring lubrication. Indeed, the only " underneath" lubrication points are nipples located at each end of the propeller shaft, but, as this component is inclined to one side of the centre line of the chassis, there should be no great difficulty in reaching the nipples.

For a six-wheeled vehicle, the Guy six-cylinder chassis shows up quite well so far as simplicity is concerned. The whole chassis is very workmanlike in • appearance, the brake work being lubricated by pipe 'leads from a battery of nipples located on the side of the chassis, whilst adjustment appears to be quite a simple matter, large wing nuts being fitted to the rods and levers which operate the shoes within each wheel drum.

It is clear that an enclosed propeller shaft minimizes considerably the number of lubrication points and "cleans " the transmission generally. In this respect Continental makers have the advantage, for there appear to be more examples of transmission of this type than in British vehicles. An excellent example of clean design with enclosed transmission is the Panhard-Levassor 21-ton " long " chassis, in which the brake rods are tubular and fitted with ball-type universal joints at each end.

The foregoing might seem to emphasize the necessity for accessibility in the chassis as well as clean design for the various components, but in a vehicle made primarily for hard use it is almost impossible to separate the two features, as it is essential that the chassis should be easy to look after,but if this object can be attained without complication, so much the better.

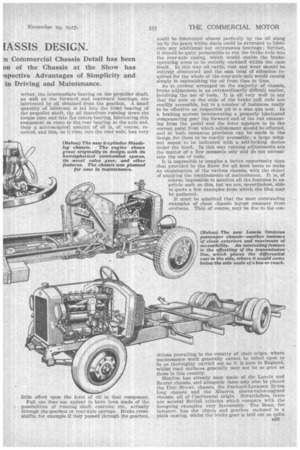

Turning now to a consideration of the engine. A square box-like exterior, whilst desirable from the point of view of cleanliness, is not a desirable attribute if such a design be obtained at the expense of accessibility. As a rule, however, the two features—simplicity and accessibility—go hand in hand. Right from the outset it must be realized that the overhead-valve engine—especially with inclined valves—is by virtue of fundamentals not So easy to design in a simple manner as a side-valve type. Au contraire, such a layout as the new Maudslay six-cylinder engine, for example, in which the correct thermal fundamentals have been obtained, is inordinately simple in maintenance layout, whilst at the same time it is particularly accessible, with all components located in get-at-able positions. In this particular engine care has been taken to avoid dismantling a whole lot of piping, manifolding, or the camshaft drive, etc., when decarbonizing, with the result that the heads (there are two) can be lifted merely by detaching the exhaust pipe. This has resulted in 9. particularly clean exterior, without any sacrifice in accessibility for the various components.

The Bean four-cylindered and six-cylinderecl engines are particularly simple, the exterior of the cylinders, crankcases, etc., being quite plain (as befits side-valve units), but the various components are quite accessible. For instance, the magneto and dynamo on both models are driven by worm gearing from the distribution drive, the two components /being pointed angularly upwards. As the drives are positive, they should be quite troublefree over a long period of time. The sleeve-valve engine lends itself admirably to a clean outline. One of the few engines of this type now fitted to commercial chassis is the Minerva, in which a particularly interesting exhaust arrangement is shown. A hot-air muffle surrounds the exhaust manifold and leads through the cylinder block to the carburetter air-intake, an extremely neat arrangement and one which is very effective in use.

For an overhead-valve power unit it would be difficult to improve limn the six-cyliudered engine of the Star "Flyer," for the exterior is quite smooth in outline, and there are no auxiliaries which (colloquially speaking) may be pointed to as being "hung on" to the main unit. Both the dynamo and magneto drives are neatly carried out and should. call for no attention what ever until the engine requires a com plete overhaul. In the interests of cleanliness, the oil mist from the overhead-valve gear is drawn into the carburetter, which thus provides good upper lubrication.

Mention must be made of the Guy engine, which, with its inclined valves, enables a very good shape of combustion chamber to be combined with a generally simple layout. Decarbonization on this engine is about as simple as it is possible to imagine that it could be, for the heads come away merely by detaching the holding-down, nuts, and the valves are get-at-able through a quickly detachable cover.

Continental engines have a very simple appearance, and in practically every instance all auxiliaries such as the dynamo, water pump, magneto, etc., are positively driven direct from the main distribution gear. Indeed, in the Lancia engine the fan itself is positively driven with the drive totally enclosed.

Engine lubrication systems still seem to offer a bone for contention, sponsors of some chassis boasting that no oil.pipes whatever are incorporated in the construction of the engine, whilst others boast that all piping is

on the exterior a the unit, so that, in the event of• failure, the trouble can be detected and very easily remedied. Following the former school of thought might be mentioned the engines fitted to Dennis vehicles, in which a full pressure system is used, the oil being led to all the major bearings of the engine by internal passages cast or drilled in the crankcase itself.

Both the four-cylindered and six-cylinclere.d Bean engines follow the same practice, Whilst the Star sixeylindered engine has only one external pipe to lead a portion of the circulating oil from the main system up to the overhead rocker gear. On the other hand, the Mandslay engine utilizes pipes throughout. The internal pipe, however, is a stiff, steel tube :which is carried in an extension of the main bearing caps, drilled passages conveying the lubricant to the crankshaft and thence to the big-end bearings of the connecting rods. The lubrication of the auxiliaries is taken almost entirely by external piping.

In conclusion, a word Of appreciation for the enormous advances made in design and construction of both the British and foreign chassis might not be out of place. Such a Show as that now staged at Olympia would positively have staggered the whole motor trade so recently as three or four years ago. Developments have been extraordinarily rapid, and manufacturers can rest assured that the user as well as the engineer fully appreciates the efforts they have made.