REVEALED TO OUR EXPERTS AT THE SHOW.

Page 49

Page 50

Page 51

If you've noticed an error in this article please click here to report it so we can fix it.

Dealing Mainly with Pointers in Design which May Not Have Been Observed by the Non-technical or Hurried Visitor.

fr HIS Commercial Vehicle Exhibi

tion of 1927 is such a huge and comprehensive display of all types of transport media that it is almost impossible for the average visitor to gain anything more than a slight conception of the numerous interesting and novel featm-es of the many .chassis on view, and yet there are hundreds of points worthy of attention, and it is with a view to gathering information regarding these that members of our staff have paid frequent visits to Olynapia and have

gone closely into the reasons for certain of the most interesting points in design. In some cases, of course, the reasons for adopting certain methods of construction or embodying special features of design are obvious, but it is surprising how many visitors are apt to miss the obvious.

In the Ransomes six-wheeled trolley-bus, for instance, stays are bolted between the centre of the upper spring-fulcrum tube and the under part of each lower spring-fulcrum bracket. Here it can clearly be understood why these are employed, but it is a method of strength

ening that is not carried out on other designs of six-wheeler.

Whilst clutches are now mainly of the single dry-plate pattern, there are still outstanding examples of the cone type. For instance, in the A-type Saurer a cone clutch is employed, and the outer cone has tongues cut in the thickness of the metal and sprung in, so that the clutch is provided with an easy takeup.

In the Dennis E-type chassis for large buses the fabric-faced cone clutch has three external clutch springs, the adjustment of which is simply effected by means of nuts and lock-nuts, whilst accessibility of the clutch is afforded by the provision a an open-topped connection between the engine and gearbox.

Adjusting Plate Clutches.

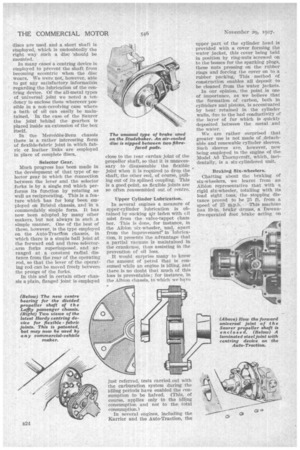

A very neat and simple form of clutch is employed on the TillingStevens Express chassis. It is a Borg and Beek of the single-plate pattern. Here a single adjustment is provided to take up wear on the fabric facings, strengthen the clutch spring and adjust the clutch stop. It is carried out in the following manner :—The clutch pedal is pushed right down, and the hexagon heads of two screws, diametrically opposed on the face of the clutch cover, are slackened, after which these screws can be moved to the right in slots to give the required results and then retightened.

After adjustment has been carried out to the limit permitted by the slots, the screws are completely removed and replaced in fresh holes which then show themselves at the other end of each slot, following which the adjustment can be continued as desired. The movement of the setscrews c,auses the plate into which they are screwed to rotate slightly and enables the toggle levers to take effect more rapidly on a cam-faced pressure plate—in other words, the toggles are moved around in relation to the cam plate.

A feature of interest on the new Saurer passenger model is that the whole of the steering gear can be moved over to the near side for use in countries where the rule of the road is "Keep to the Right." This is a point which might receive some consideration from those of our manufacturers who are interested in foreign markets.

Universal Joints.

It is seldom that laminated-steel joints are to be found in a propeller shaft, but such is the case in the Auto-Traction chassis, where, however, the forward portion of the twopiece shaft is kept in line with the gearbox, and consequently the joint does 'little else but make allowance for frame flexion. Incidentally, a centring device is employed in this joint, as well as in the others of the flexible-fabric pattern used elsewhere on the shaft: The laminations take the form of complete rings. The fabric joint is still in evidence on many models, but is mostly to he found 'between the engine and the gearbox, where there is but little misalignment between the shafts it couples ; in nearly all cases two discs are used and a short shaft is employed, which is undoubtedly the right way such a disc 'should be mounted.

In Many cases a centring device is employed to prevent the shaft from becoming eccentric when the disc wears. We were not, however, able to get any satisfaCtory information regarding the lubrication of the centring device. Of the all-metal types of universal joint we noted a tendency to enclose them wherever possible in a non-revolving ease where a bath of oil can easily be maintained. In the ease of the Saurer the joint behind the gearbox is placed inside an extension of the box Itself.

In the Merct5des-Benz chassis there is a rather interesting form or flexible-fabric joint in which fabric or leather links are employed in place of complete discs.

Selector Gear.

Much progress has been made in the development of that type of selector gear in which the connection between the lever and the selector forks is by a single rod which performs its function by rotating as well as reciprocating. This is a feature which has for long been employed on Bristol chassis, and in a commendably, simple form. It has now been adopted by many other makers, but not always in such .a simple manner. One of the best of these, however, is the type employed on the Auto-Traction chassis, in which there is a simple ball joint at the forward end and three selector., arm forks superimposed, and arranged at a constant radial distance from the rear of the operating rod, so that the lever of the operating rod can be moved freely between the prongs of the forks.

In this and in certain other chassis a plain, flanged joint is employed

close to the rear cardan joint of the propeller shaft, so that it is unnecessary to disassemble the flexible . joint when it is required to drop the shaft, the other end, of course, pulling out of its splined coupling. This Is a good point, as flexible joints are so often reassembled out. of centre.

Upper Cylinder Lubrication.

In several engines a measure of upper-cylinder lubrication is obtained by sucking ajr laden with 61 mist from the valve-tappet chamber. This is done, for instance, in the Albion six-wheeler, 'and, apart from the improvement. in lubrication, it presents the advantage that a partial vacuum is maintained in the crankcase, thus assisting in the prevention of oil loss.

It would surprise many to know the amount of petrol that is consumed while an engine is idling, and there is no doubt that much of this loss is preventable; for instance, in the Albion chassis, to which we have upper part of the cylinder head is provided with a cover forming the water jacket, this cover being held in position by ring-nuts Screwed on to the bosses for the sparking plugs, these nuts pressing on the rubber rings and forcing the cover on to a rubber packing, This method of construction enables all deposit to be cleaned from the water jackets.

In our opinion, the point is one of importance, as we believe that the formation of carbon, both in cylinders and pistons, is accentuated by heat retained in the cylinder .walls, due to the had conductivity of the layer of fur which is quickly deposited between the metal and the water.

We are rather surprised that greater use is not made of _detachable and renewable cylinder sleeves. Such sleeves are, however, now being employed in the engine of the Model A6 Thornycroft, which, incidentally, is a six-cylinderecl unit.

. Braking Six-wheelers.

Chatting about the braking of six-wheelers, we learnt from an Albion representative that with a rigid six-wheeler, totalling with its load eight tons, thestopping distance proved to be 25 ft. from a speed, of 25 m.p.h. -This machine has 19-in. brake drums, a Dewandre-operated foot brake acting on

the wheels of the third axle only and a hand brake operating on ' those on the second axle. Practically all radiators are now . equipped with water connections secured by flanges, so that it is unnecessary to break rubber joints when removing the connections.

• This is a point which has long been advocated in this journal.

Several interesting little improvements have been made in the latest ly chassis. For instance, the rocker arms are now spring-loaded at each side so that noise due to side chatter is avoided. Another point is in the arrangement of the oil troughs for the big-ends. These troughs are held in pairs in a pressed-steel casing, at one end by a crossbar with a central stud and nut and at the other end by the carrier of the oil-feed nipples, the removal of which enables the oil passages to be cleaned out Much more attention now appears to be given to the accessibility of certain important engine auxiliaries. Some time ago the Citroen designers adopted a method of mounting the fan on the front of the dynamo spindle and driving' both by a single V Tubber belt. A similar method is now utilized on the Unic. The arrangement affords easy access to the dynamo and presents the advantage that the unit, is kept perfectly cool. .

A neat method of mounting is employed on the Dennis G-type chassis. Here the dynamo is carried in an eccentrically bored aluminium casting mounted within a bracket • bolted to the cylinder head, and the eccentric housing can be turned to afford adjustment of the link belt. Accessibility of the dynamo has also been greatly improved on the Bristol chassis. It is now accommodated in a vertical position at the off-side rear end of the cylinder block ; formerly it was at the froW: end.

In the Bean passenger chassis the dynamo and distributor are both mounted at an angle at the off side of the timing case; here, again, accessibility is a strong point.

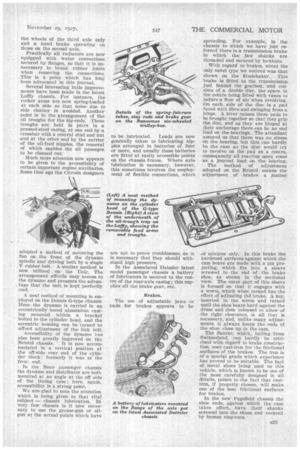

We are glad to note the attention which is being given to that vital subject — chassis lubrication. In very few chassis is it new necessary to use the grease-gun or oilgun at the actual points which have

to be lubricated. Leads are DOW generally taken to lubricating nipples arranged in batteries of four or more, and usually these batteries are fitted at easily accessible points on the chassis frame. Where axle lubrication is necessary, however, this sometimes involves the employment of flexible connections, which are apt to prove troublesome, as it is necessary that they should withstand high pressure.

In the Associated Daimler latest model passenger chassis a battery of lubricators is secured to the centre of the rear-axle casing ; this supplies all the brake gear, etc. spreading. For example, in the chassis to which we have just referred there is a transmission brake in which the jaw shanks are threaded and secured by locknuts.

With regard to brakes, about the only novel type we noticed was that shown on the Studebaker._ This brake is fitted to the transmission just behind the gearbox; and consists of a double disc, the space in the centre being fitted with vanes to induce a flow of air when revolving. On each side of the disc is a pad faced with fibre and swinging from a hinge. A lever causes these pads to be brought together so that they grip the ,disc, and as they are hinged at their anchorage there can be no end load on the bearings. The attendant assured us that there was no stress on the bearing, but this can hardly be the case as the disc would try to revolve on the pad as a centre, consequently all reaction must come as a journal load on the bearing.

The method of adjustment adopted on the Bristol makes the adjustment of brakes a matter

.of minutes only. In this brake the hardened surfaces against which the cam bears are made with a pin projecting, which fits into a sleeve screwed to the end of the brake shoe, as shown in the sectional view. The outer part. of this sleeve is formed so that it engages with a • worm, which when turned has the effect of adjusting the brake. A key, inserted in the worm and turned until the shoe bears hard against the drum and then released to allownf the right clearance, is . all that is necessary, and, unlike many adjustments, it always keeps the ends of . the shoe close up to the cam. •

The Saurer, which, hailing from Switzerland, can hardly be criticised with regard to brake construction, uses cast-iron for the frictional surfaces of the brakes. The iron is of a special grade which experience has proved to be suitable. The fact of metal shees being used on this vehicle, which is known to be one of the most carefully designed in all details, points to the fact that castiron, if properly chosen, will make one 'of the best frictional surfaces for brakes.

In the new Pagefield chassis the shoe ends, against which the cam takes effect, have their shanks screwed into the shoes and secured by bronze ring-nuts.