HINTS ON MAINTENANCE.

Page 129

If you've noticed an error in this article please click here to report it so we can fix it.

Obtaining Longer Life from Perch Bars.

WHEN overhauling a commercial vehicle, it is frequently found that the rear suspension shaft of the back springs, or the perch bar, as it is often called, is worn only slightly, this wear naturally occurring on the underside where the load is taken and which is seldom adequately lubricated, because there is sac/ slight-movement at the two points where the shackles bear.

To avoid the necessity of replacing the shaft or weakening it by grinding or turning down and fitting larger bushes, it Can usually be reversed in its brackets so that new bearing surfaces are presented for further wear.

In some vehicles detachable sleeves are fitted over the shaft ends, and these sleeves can be turned even more easily than the shaft itself. They are usually held by taper pins or well-fitted bolts. Great, care should be taken that they are perfectly tight after the reversing process has been carried out.

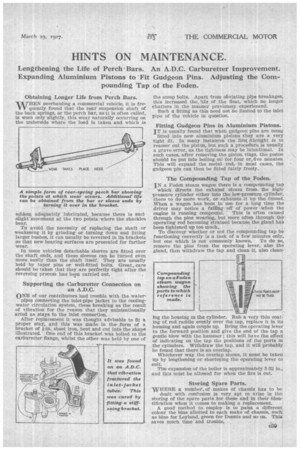

Supporting the Carburetter Connection on an A.D.C.

ONE of our contributors had trouble with the water pipes connecting the inlet-pipe jacket to the coolingwater circulation system, these breaking as the result of vibration for the reason that they unintentionally acted as stays to the inlet connection.

After replacement it was thought advisable to fit a proper stay, and this was made in the, form of a bracket of i-in. sheet iron, bent and cut into the shape illustrated. One end of this bracket was bolted to the carburetter flange, whilst the other was held by one of

the sump bolts. Apart from oEviating pipe breakages, this increased the, life of the float, which no longer chatters in the manner previously experienced, Such a fitting as this need not be limited to the inlet pipe of the vehicle in question.

Fitting Gudgeon Pins in Aluminium Pistons. IT is usually found that when o pins are being

fitted into new aluminium pistons they are a very tight fit. In many instances the first /thought is to reamer out the piston, but such a procedure is usually a grave error, as the tightness may be intentional. la such cases, after removing the piston rings, the. -piston should be put into boiling oil for four or,five minutes. This will expand the metal and, in most cases, the gudgeon pin can then be fitted fairly freely.

The Compounding Tap of the Foden.

IN a Foden steam wagon there is a compounding tap which directs the exhaust steam from. the highpressure cylinder either into the low-pressure cylinder, there to do more work, or exhausts it up the funnel. When a wagon has been in use for a long time the driver may notice a falling off of power when the engine is running compound. This is often caused through the pins wearing, but more often through the operating rod becoming strained because the gland has been tightened up too much. •

To discover whether or not the compounding tap be functioning correctly :s a task of a few minutes only, hut one which is not commonly known. To do so, remove the pins from the operating lever, also the gland, then withdraw the tap and clean it, also clean

ing the housing in the cylinder. Rub a very thin coating of red raddle evenly over the tap, replace it in its housing and again couple up. Bring the operating lever to the forward position and give the end of the tap a gentle blow with the hammer ; this will have the effect of indicating on the tap the positions of the ports In the cylinders. Withdraw the tap, and it will probably be found that there is an overlap.

Whichever way the overlap shows, it must be taken up by lengthening or shortening the operating lever to suit.

This expansion of the boiler is approximately 3-32 in., and this must be allowed for when the fire is out.

Storing Spare Parts.

WHERE a numbef, of makes of chassis has to be dealt with confusion is very apt to arise in the storing of the spare parts tor these and in their identification when it comes to making a replacement. A good method to employ is to paint a different colour the bins allotted to each make of chassis, such as blue for Leyland, green for Dennis and so on. This saves much time and trouble.