NO WAND

Page 52

Page 53

Page 54

Page 57

Page 58

If you've noticed an error in this article please click here to report it so we can fix it.

ING GIPSY

By Anthony Ellis ci7 FOLLOWING its introduction early in 1958, the Austin Gipsy 4 x 4 utility was justly acclaimed for the excellent off-the-road performance, made possible largely by independent rubber suspension of all wheels. However, some who tested it, including The Commercial Motor, were less happy with the suspension and steering qualities on made roads. Heavy steering on cornering and wander when travelling in a straight line were reported.

Now, in the Gipsy Series II, the Austin Motor Co., Ltd., have almost eliminated these characteristics, to the detriment of cross-country ability. But the latest model is undoubtedly a far better compromise than its predecessor, for small general-purpose vehicles of this type are often destined to serve as part of the gentleman farmer's fancy dress and, in such roles, spend most of their life on good surfaces. They must be reasonably docile under all conditions, although it would be unreasonable to demand private-car standards of road-holding.

The changes in handling have been achieved by only detail modifications. These amount to the use of softer rubber in the front and rear Flexitor trailing-arm suspension units to increase overall deflection by some 50 per

cent., and a revised steering layout, which now comprises a divided track rod operated: through a frame-mounted idler shaft. The box-section trailing suspension arms are fabricated from a heavier-gauge material and, although similar in design to the original arms, are stronger.

To accommodate the increased travel of the rear suspension and improve ground clearance, lever, type dampers at all wheels have replaced the telescopic units. At the front, the swivel-axle supports and castings have been redesigned for greater rigidity, whilst rubber packing is now interposed between the rear differential unit and the frame.

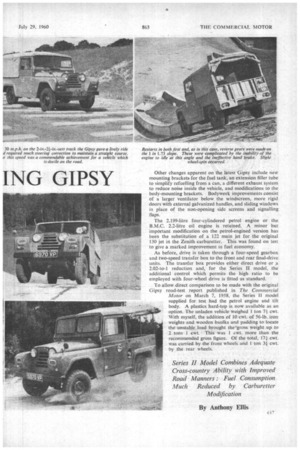

Other changes apparent on the latest Gipsy include neW mounting brackets-for the fuel tank, an extension filler tube to simplify refuelling from a can, a different exhaust System to reduce noise inside the vehicle, and modifications to the body-mounting brackets. Bodywork improvements consist of a larger ventilator below, the windscreen, more rigid doors with external galvanized handles, and sliding windows in place of the non-opening side screens and signalling flaps.

The 2.199-litre four-cylindered petrol engine or the B.M.C. 2.2-litre oil engine is retained. A minor but important modification on the petrol-engined version has been the substitution of a 122 main jet for the original 130 jet in the Zenith carburetter. This was found on test to give a marked improvement in fuel economy.

As before, drive is taken through a four-speed gearbox and two-speed transfer box to the front and rear final-drive units. The transfer box provides either direct drive or a 2.02-to-1 reduction and, for the Series II model, the additional control which permits the high ratio to be employed with four-wheel drive is fitted as standard.

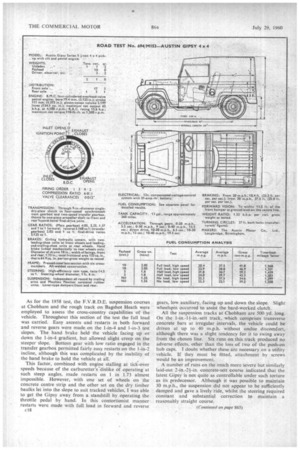

To allow direct comparison to be made with the original Gipsy road-test report published in The Commercial Motor on March 7, 1958, the Series II model supplied for test had the petrol engine and tilt body. A plastics hard-top is now available as an option. The unladen vehicle weighed I ton 71 cwt. With myself, the addition.of 10 -cwt. of 56-1b. iron weights and wooden baulks and padding to locate the unstable. load brought thegross weight .up. to 2. tons • 1 cwt. This was '1 cwt. more than. the recommended gross figure. Of the IOW, 171 cwt. Was carried.by the front wheels and I ton31 cwt. by thefl rear wheels. As for the 1958 test, the F.V.R.D.E. suspension courses at Chobham and the rough track on-Bagshot Heath were employed to assess the cross-country capabilities of the vehicle. Throughout this section of the test the full load was carried. Easy ascents and restarts in both forward and reverse gears were made on the 1-in-4 and 1-in-3 test slopes. The hand brake held the vehicle facing up or down the 1-in-4 gradient, but allowed slight creep on the steeper slope. Bottom gear with low ratio engaged in the transfer gearbox permitted fairly easy restarts on the 1-in-2 incline, although this was complicated by the inability of the hand brake to hold the vehicle at all.

This factor, combined with engine stalling at tick-over speeds because of the carburetter's-dislike of operating at such steep angles, made restarts on 1 in 1.73 almost impossible. However, with one set of wheels on the concrete centre strip and the other set on the dry timber baulks let into the slope to suit tracked vehicles, I was able to get the Gipsy away from a standstill by operating the throttle pedal by hand. In this contortionist manner restarts were made with full load in forward and reverse

I

gears, low auxiliary, facing up and down the slope. Slight wheelspin occurred to assist the hard-worked clutch.

All the suspension tracks at Chobham are 500 yd. long. On the 1-in.-14--in.-sett track, which comprises transverse concrete bars at irregular intervals, the vehicle could be driven at up to 40 m.p.h. without undue discomfort, although there was a slight tendency for it to swing away from the chosen line. Six runs on this track produced no adverse effects, other than the loss of two of the push-on hub caps. I doubt whether these are necessary on a utility vehicle. If they must be, fitted, attachment by screws would be an improvement.

A number of runs on the much more severe but similarly laid-out 2-in.-21-in. concrete-sett course indicated that the latest Gipsy is not quite as controllable under such torture as its predecessor. Although it was possible to maintain 30 m.p.h., the suspension did not appear to be sufficiently damped and gave a lively ride, whilst the steering required constant and substantial correction to maintain a reasonably straight course.

Yet I believe that there are few, if any, vehicles, other than much more expensive military designs, which could have traversed the track at this speed. The Gipsy falls. down only by comparison with the extremely high standard set by the original model.

The suspension is entirely adequate when dealing with bumps of lesser magnitude. On the pave track, 40 m.p.h. could be maintained without difficulty. Some form of grab rail on the facia for the passenger would be an advantage, as the bench seat provides little location.

The cross-country course on Bagshot Heath was dry, with a hard surface, on the day of the test. A circuit of the Alpine course with full load showed that the Gipsy is stilt very much a go-anywhere vehicle, but has to be taken over ruts and severe corrugations with caution if the driver has any concern for his personal comfort. Increased Suspension travel appears to have reduced the efficiency of the springs in dealing with really severe cross-country conditions at speed.

But it is safe to say that few Gipsys in normal service will be used on such difficult terrain. Later tests over loose-surfaced, pot-holed tracks and open country on the South Downs showed the Gipsy in its element. Almost any speed could be maintained without discomfort or undue concentration on driving.

The softer suspension has increased permissible wheel movement by 50.per cent., giving about 9 in. total deflection from full bump to full rebound. Accompanying this is a change in castor angle for the front wheels of 40 degrees. One would expect this to give rise to even more peculiar steering characteristics on hard roads than occurred with the Series I model, for which the total change in castor angle was 27 degrees.

found that this was not so. It results in a•softer ride, whilst no wander was apparent when travelling in a straight line at any speed, even when fairly strong side winds were encountered on the motorway. The vehicle understeers on corners to make the steering heavier as the rate of turn increases, but this is not objectionable. Fast cornering can induce a fair amount of roll, but tyre squeal, which was noted with the earlier model, is largely absent.

Braking tests showed up another characteristic arising from the softer suspension. Sharp brake applications caused the complete vehicle to "curtsy " as the trailing-arm suspension units deflected under the increased load. From 20 m.p.h. this effect was fairly mild, but from 30 m.p.h. it was severe and led to marked deviation from a straight course. Nevertheless, the braking figures recorded were satisfactory, whilst the wheels did not lock from either speed.

The hand brake, as I had expected from its performance on the test slopes, was not particularly effective, producing a mean reading on the Tapley meter of 26.5 per cent. when applied from 20 m.p.h.

The change in main-jet size has produced a commendable improvement in the fuel-consumption rate. Compared

with the Series I Gipsy, tested over the same six-mile out-and-return course, the Series II model gave nearly 4 m.p.g. more when operating at high speed—up. to 55 m.p.h.—with full load, returning a figure of 20.4 m.p.g.

Similar economies were apparent under all other conditions of load and speed. I am surprised that so large an improvement could be achieved by -this modification, but Austin are adamant that this was the only change made. Little or no power has been lost by the reduction in jet size, as shown by the acceleration times recorded. These were almost identical with those obtained with the earlier Gipsy, although the later model was running at a slightly higher gross weight.

Cooling efficiency was checked on the 4-milelong Bison Hill. From a standing start the ascent was made in 2 minutes 5 seconds. Second gear, the lowest ratio used, was engaged for .a total time of 20 seconds. ' For most of the distance the engine. waS pulling hard in third gear to maintain a speed between 25 m.p.h. and 30 m.p.h. In an ambient temperature of 74° F. the coolant temperature was 167° F. at the top of the hill, having risen by 5° F.

The Gipsy was then coasted down the hill out of gear with the speed kept down to 20 m.p.h. by the foot brake. As usual, top gear and full throttle were applied against the brake to offset the decreasing gradient towards the bottom.

Because of the curtsying effect when braking, it was not possible to take a Tapley reading during the " crash " stop that followed, as the meter consistently recorded over 100 per cent. However, the brakes showed no excessive fade.

A puzzling occurrence during the test was the disintegration of the outer universal joint On the off-side rear drive shaft.

This happened on the motorway after I had done about 50 miles of sustained running at speeds up to 55 m.p.h. It must, I think, have been damaged originally during the cross-country tests, because Hardy-Spicer have as yet been unable to diagnose a fault in material.

Generally, the Gipsy is pleasant to drive. Engine and transmission are quiet, whilst the exhaust is now less audible. The pedals, particularly that for the 9-in.-diameter clutch, are heavier in action than is normal for a vehicle of this weight and this was liable to become tiring in dense traffic.

In all, the Series II Gipsy represents a substantial improvement on the original model for general use and should now establish, itself in the specialized but wide market at which it is aimed. 'The standard vehicle with petrol engine cost £650. The price is £755 with the oil engine.

At low speeds and heavy loadings (up to 18 tons per sq. in.) the coefficient of friction of a DU bearing is at a minimum and the coefficient rises only slightly with an increase in speed or a reduction in loading. The minimum coefficient value ranges from 0.05 to 0.10, whilst the normal coefficient lies between 0.10 and 0.16. This is particularly important for steering connections, where the loading is highest at low rotational speeds.

Any bearing, even when lightly loaded, generates a certain amount of heat, and if there is no lubricant flow most of this heat must be conducted away from the bearing surface. Normal plain plastics materials are suitable for only lightly loaded bearings, because of their poor heat conductivity.