The First British Hydraulic Shovel

Page 12

If you've noticed an error in this article please click here to report it so we can fix it.

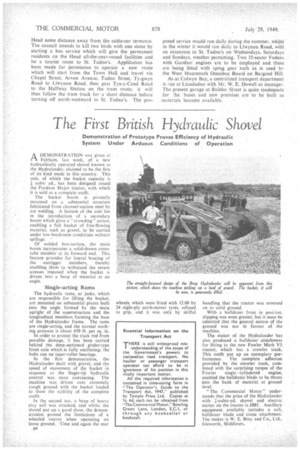

Demonstration of Prototype Proves Efficiency of Hydraulic System Under Arduous Conditions of Operation A DEMONSTRATION was given at Feltham. fast week, of a new hydraulically operated shovel known as the Hydraloader, claimed to be the first of its kind made in this country. This unit, of which the bucket capacity is cubic yd., has been designed round the Fordson Major tractor, with which

it is sold as a complete outfit. The bucket boom is pivotally mounted on a substantial structure fabricated from channel-section steel by arc welding. A feature of the unit lies in the introduction of a secondary boom which gives a "crowding" action, enabling a full bucket of free-flowing material, such as gravel, to be carried under low-headroom conditions without spillage. '

• Of welded box-section, the main boom incorporates a solid-drawn crosstube member at its forward end. This feature provides for lateral bracing of the outrigger members, thereby enabling them to withstand the severe stresses imposed when the bucket is driven into a heap of material at an angle.

Single-acting Rams

The hydraulic rams, or jacks, which are responsible for lifting the bucket, are mounted on substantial pivots built into the angle formed by the main upright of the superstructure and the longitudinal members forming tire base of the Hydraloader frame. The rams are single-acting, and the normal working pressure is about 450 lb. per sq. in.

In order to protect the track rod from possible damage, it has been carried behind the deep-sectioned girder-type front axle which is fully oscillating; the hubs run on taper-roller bearings.

In the first demonstration, the Hydraloader dealt with gravel, and the speed of movement of the bucket in response to the finger-tip hydraulic control was most convincing. The machine was driven over extremely rough ground with the bucket loaded to show the stability of the complete outfit.

In the second test, a heap of heavy clay soil was attacked, and whilst the shovel put up a good show, the demonstration proved the limitations of a wheeled tractor when operating on loose ground. -Time and again the rear Es4 wheels, which were fitted with 12.00 by 24 eight-ply earth-mover tyres, refused to grip, and it was only by skilful handling that the tractor was reversed on to solid ground.

With a bulldozer front in position, slipping was even greater, but it must be admitted that the general nature of the ground was not in favour of the machine.

The maker of the Hydraloader has also produced a bulldozer attachment for fitting to the new Fowler Mark V5 tractor, which has a crawler track. This outfit put up an exemplary performance. The complete adhesion provided by the crawler track, combined with the surprising torque of the

Fowler single -cylindercd engine, enabled the bulldozer blade to be thrust into the bank of material at ground level.

"The Commercial •Motor" understands that the price of the Hydraloader with 1-cubic-yd. shovel and electric starter on the tractor is 1885. Ancillary equipment available includes a cab, bulldozer blade and crane attachment. The maker is W. E. Bray and Co, Ltd., Isle-worth, Middlesex.