Kom Drivers kMechanics

Page 36

Page 37

If you've noticed an error in this article please click here to report it so we can fix it.

TEN SHILLINGS WEEKLY is paid for the best cornmunication received, and one penny a line of ten words for anything else published, with an allowance for photographs.

Send as an account of any sbecial incident of your work or experience. If suitable, we will edit yoiw notes, supfily a sketch when required, and bay you for everything published. Mention your employer's name, in confidence, as evidence of good faith. Address to The Editor, THE COMMERCIAL MOTOR, Rosebery Avenue, London, E.G.

Light up your Lamps at

8,40 on Thursday ; 5.42 on Friday ; 5.44 on Saturday; 5.48 on Monday ; 5.50 on Tuesday ; 5.52 on Wednesday.

Twist-drills. The Evils of Incorrect Grinding.

The sender of the following communication has been awarded the 10s, prize this week.

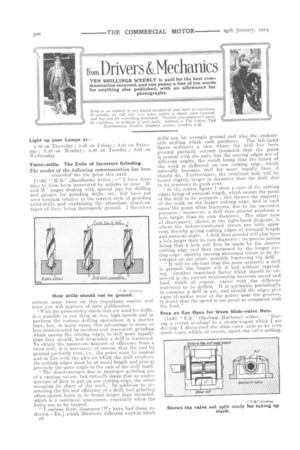

[1429] " H.13." (Sandbach) writes :—" I have float time to time been interested by articles in your D. and M.' pages dealing with special jigs for drilling and gauges for grinding drills, etc., but have not seen mention relative to the correct style of grinding twist-drills and explaining the attendant disadvantages of their being improperly ground. I therefore How drills should not be ground, submit some hints on this important matter and trust, you will approve of their publication.

"With the present-day steels that are used for-drills, it is possible to run them at very high speeds and so perform the various drilling operations in a shorter time, but, in many cases, this advantage is more or less counteracted by careless and inaccurate grinding which causes the cutting edges to dull more rapicllthan they should, and invariably a drill is fractured. To obtain the maximum amount of efficiency from a twist-drill, it is necessary, of course, that the tool be ground perfectly true, i.e., the point must be central and in line with the axis on which the drill revolves, the cutting edges must be of equal length and also at precisely the same angle to the axis of the drill itself.

" The disadvantages due to improper grinding are of a varying nature, but virtually mean that an undue amount of duty is put on one cutting edge, the other escaping its share of the work. In addition to decreasing the life and efficiency of a drill, bad grinding often causes holes to be bored larger than intended, which is a continual annoyance, especially when the holes are to be tapped.

"I enclose three diagrams [We have had these redrawn.—End which illustrate different ways in which r2 drills an be wrongly ground and also the undesirable drilling which each produces. The left-hand figure indicates aease where the drill has been ground partially correct insomuch that the point is central with the axis, but the cutting edges are of different angles, the result being that the brunt of the work is deflected on one cutting edge, which naturally becomes dull far more rapidly than it should do. Furthermore, the resultant hole will be bored slightly larger in diameter than the drill, due to its tendency to push over. " In the centre figure I show a case of the cutting edges being of unequal length, which causes the point of the drill to be eccentric ; this throws the majority of the work on the larger cutting edge, and in such cases the point often fractures, due to the excessive pressure ; moreover, a drill thus ground produces a hole larger than its own diameter. The other case of discrepancy, shown in the right-hand diagram, is where the before-mentioned errors are both apparent, thereby giving cutting edges of Unequal length and unequal angle. A drill thus ground will also bore a hole larger than its own diameter ; its precise action being that a hole will first be made by the shorter cutting edge and then increased by the longer cutting edge ; thereby causing abnormal strain to be developed on the point, possibly fracturing the drill.

" It will be obvious that the more correctly a drill is ground, the longer will it last without regrinding. Another important factor which should be observed is the correct relationship between speed and feed, which of course, varies with the different materials to he drilled. It is advisable periodically to examine a drill in use, and should the edges give signs of undue wear at the points near the grooves, it shows that the speed is too great as compared with the feed."

Keep an Eye Open for Worn Slide-valve Nuts.

11430] " ES." (Seaham Harbour) writes :—" During a recent overhaul to a steam-wagon which I am driving, I discovered the slide-valve nuts to be very n^uch worn, which, of course, upset the valve-setting.

Instead of scrapping the nuts, entailing a delay in ordering new ones, I considered that, with but little trouble, I could repair the worn ones satisfactorily to enable them to be refitted and yet affond the exact setting of the valve to be effected.

" The sketch which 1 enclose [We. have had this redrawn.--En.] shows the very easy method of repair. I put a, saw-cut through the middle of the nuts, as shown, and filed a. little metal Qa the inner faces of each half, to enable me to re-set the valve exactly, and screwed them tightly up to the bosses of the slide-valve.

" I took the cover off about six weeks afterwards to examine the repair, and found that it was still quite effective; moreover, the setting had not been interfered with in any way."

To Those who Favour the Lead Lap.

[14a1] "J.P." (Eastbourne) writes : —" The lappingtool described by H.B.S.' (letter No. -API) is useful for finishing off journals, but I have found that such

::. device fails in the case of bearings which have worn eval or are otherwise out of 'round.' as, by it, the nrinding action is applied to the low as well as the high parts, and, although giving a good finish, it does not alter the profile.

"1 am sending a description of an easily-niacin tool, together with a. sketch [We have had this redrawn.-:!.:1).] showing same, which obviates the objection -which I have pointed out. The clamping portion of the outfit consists of two pieces of bar iron, the deneneions for the one 'I made being l ins. wide by ev thick, the part to make the cap is 12 ins, long, and the remaining portion, including the allowance for a handle, 1 ft. 8 ins. The size, however, will vary with individual cases.

It should be bent to the shape shown, and to get it circular I forged the iron to a templet. To make the lapping part, two strips of wrought-iron were procured in. thick, their width being equal to the length of the journal. These I forged circular to fit inside the clamp, in halves. Before the halves are placed in position, however, two holes in. diainetet: were drilled through both pieces to enable lead, which is eventually poured in, to be held in place.

" The rig is then placed on a fiat surface, fire clay built up round it, and the centre portion filled with the molten lead. The tool is then set up in the lathe :Ind bored out to suit the diameter of the crankshaft journal. It will be found that with this outfit one is able to effect lapping with ahigh degree of accuracy -which can only be equalled by a proper grinding machine.

"I do not advocate using emery powder, as T find thatthe grains work into the pores of the metal, and it is with great difficulty that they are removed, so that the smooth surface required is somewhat unpaired." Hints on Stud-holes and Broken Taps.

[1,M2]" E.G..R." (Gravesend) writes:— "Possibly the following hints on tapping-holes, in order to ensure that the studs will enable the parts to be fitted to face up square, will be of interest to readers of your 'ii and M.' pages. " When tapping a hole, a good method to find whether the tap starts perpendicular isto fit on a nut and run it down against the face of the work piece. This will show in a moment in which direction the tap inclines, if at all. Should it be found that the tap has been started out of tree, then work the wrench or bar in order to bring it. square again; if the nut locks itself when working the tap in, the latter should be reversed in ordee to release it.

"This method will be an easier and better one than the usual way of working the tap to a try-square by mere judgment, but care must be taken when using small taps, as they are fragile and are likely to snap without WFLIII in g.

" The exteaction of a tap which has broken flush with the face of the part being operated on often presents much difficulty, particularly to a beginner. Should an occasion arise to extract a broken tap, first try to back the broken portion out with a small nailpunch. and hammer ; if this proves unsuccessful, procure a short piece of mild-steel rod of the same diameter as the tap, and drill a hole in at one end, of a diameter equal to the centre portion of the tap. Then file the end of the part which has been drilled and leave three or four short prongs.. the number being to suit the groove:s on the tap which has been broken. " Upon inserting the prongs in the grooves, it will be often found thatthe trip may be easily backed out. 11 this fails, however, a deal must be used, the part heated to adull red and then buried in dry lime or sawdust, in order to soften the tap. Then send the drill into the centre part. of the tate and afterwards, with a small chisel, pick out. that which is left. "Shoeld it not be practicable to heat the Dart in the fire, use a blow-lamp. The fact remains that the tap umet be softened or the drill will make no impression on it. "I find that either turpentine or paraffin ac s as a good lubricant for the drill in such cases."

Appreciation. [1133; G.141." (Weaste) writes:—" Allow me to thank you for the 1.0e. prize recently awarded me for my contribution respecting the manufacture and attachment of adriving mirror for use on aste-am wagon. " As a dtiver. I can assure you that I am much interested in the D -and IL' pages, and from time to time pick up some very useful hints and tips from those pages:'