York revive transporter

Page 20

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

THE UK CAR transporter market is quite small — most of the units are run by little more than half a dozen operators. For them, the growing tide of imported vehicles has often meant not only a growth in business, but more efficient use of their vehicles because loads are available for both the outward and homeward journeys.

There are fewer than 2,000 units in total operating in the British Isles, and each one is credited with a service life of 10 to 11 years. There is only a small export trade, and home market production is less than 150-200 a year. Sub-divided between the three prominent manufacturers in this field, each manufacturer's share looks very small indeed.

To put the volume into perspective, York Trailers' annual share of the transporter market represents less than one week's production of flat-bed trailers — so it is all the more surprising that York has done an aboutface and started to build them again, after stopping production four years ago.

Shortly after Anthony Carrimore became part of the York

group of companies in 1975, operations were slimmed down in order to make economies and the transporter given the axe.

Alan Cooper moved from the Anthony Carrimore works at Durham to re-open the York plant at Corby. Two years later production is back into full swing at Corby and the experienced workforce had the capability once more to extend the product range.

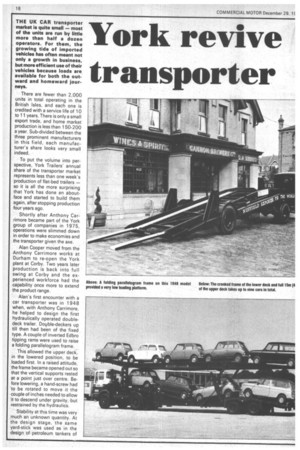

Alan's first encounter with a car transporter was in 1948 when, with Anthony Carrimore, he helped to design the first hydraulically operated doubledeck trailer. Double-deckers up till then had been of the fixed type. A couple of inverted Edbro tipping rams were used to raise a folding parallelogram frame.

This allowed the upper deck, in the lowered position, to be loaded first. In a raised attitude, the frame became opened out so that the vertical supports rested at a point just over centre. Before lowering, a hand-screw had to be rotated to move it the -couple of inches needed to allow it to descend under gravity, but restrained by the hydraulics.

Stability at this time was very much an unknown quantity. At the design stage, the same yard-stick was used as in the design of petroleum tankers of the day, with a maximum c of g height of 2.1m (6ft 10in). Today York has progressed to the Mk II, but the maximum height remains the same. Additional features such as the wide spring base assists stability still further.

The Mk II is the basic model which can be modified or added to suit the individual customer's. requirements.

It is a two-tier tandem-axle semi-trailer measuring 15m(49ft) in length, with a cranked frame catering for movement of cars and light commercial vehicles'. The lower deck is the shorter by 2.7m (9ft). Together the two-deck combination will accommodate either nine Minis, seven Cortinas or six Jaguars. The top deck can carry two YRCI Bedford bodyless coach chassis at one time.

The chassis is of peripheral I-beam all-welded construction, while the vertical front pivot supports are made from 89mm (3.5in) hollow square boxmembers clad in steel sheeting. The cladding is added not only to improve the visual aspect, but to give it some useful purpose. Foot holds and a handrail have been added, providing a second means of access to the upper. deck'.

Hundreds of pressed louvres in the well of the standard 0.53m (21 in) wide tracking provide grip for the vehicle tyres. The tracks, located at the edges of the trailer, cater for full-width vehicles. There are 32 anchoring bollards, consisting of barrel, rachet, 5ft of 5cwt swl chain and hook, placed at intervals throughout the vehicle length providing adequate means of load restraint.

The Edbro tipping gear has long since been replaced by in-house components, Anthony Carrimore's twin-stage hydraulic rams, which power an adjustable hinged scissor link. Loading ramps at the rear slide telescopically into position from beneath the track, presenting a 12.5° approach angle for loading. Side and tail-lamp clusters pivot clear of the wheels.

This type of unit is favoured in the home market but not so much on the Continent, where swing-out and height regulations prohibit its use in some Countries. For them the rigid/ drawbar outfit fits the bill, even though the fixed structure of the top deck built close to the cab roof can cause complications when vehicles with tilt cabs are used.

Oby Bill Brock