Alloy pays off in payloac

Page 90

Page 91

If you've noticed an error in this article please click here to report it so we can fix it.

TIPPER operators are still going for the more expensive alloy bodies in a big way.

In pay load conscious Britain. aluminium is streets ahead, even though the price gap between alloy and steel continues to widen.

Neville Industries, of Mansfield, are specialists in the construction of tipper bodies. For some time it has been aware of the importance placed upon maximum pay load capacity by its customers.

As a result its Ultrahte all welded body has been produced.

Weight for weight it is equal in strength to its NeviHoy body, which with side posts has the appearance of being more robust. Both are made from the same aluminium alloy having an impact strength three times greater than that of steel.

Simple but strong in construction, the Ultralite, which won a Design Council award in 1976, consists of a sheet of aluminium rolled into a flat bottomed section. This is supported along the top, front and rear edges by a rigid frame of extruded aluminium box section in such a way as to remove the need for the con ventional side framing.

The floor section is supported from below by two very strong longitudinal 'V' shaped beams providing a much larger area of support than the usual type of subframe.

Because there are no crossmembers, the old problem of transverse floor buckling, often the cause of restriction to load discharge, has been eliminated.

Any distortion likely to occur should only be longitudinal which, it could be argued, will only serve to strengthen the floor section.

Tipper bodies have to be able to withstand severe shock during loading as well as stresses during transit. The load which creates the largest stresses in any body of this type is one of hot road stone.

Loaded at a temperature of about 175 c (350 f) it can produce a growth of about 25rnm (1n) over a 5.5m (18ft) body length due to the expansion rate of aluminium.

The longitudinal 'V' section backbone construction is claimed to be particularly suited to this type of use. The lack of intermediate side posts provides an ideal recess to accept a continuous 63mm (2.5in) layer of glass fibre insulation material retained by an outer skin of sheet aluminium.

The new body does however have a minor drawback. Where under floor rams are a must, the heavier Nevilloy would be recommended as the Ultralite body is suitable only for use with front mounted rams.

Variations on the standard design, with a 6mm (6.25in) floor and 4mm (0.19in) side skin, are available for any make of chassis from 1.52 tons (30cwt) unladen up to 30.6 tonnes (30 tons) laden. tonnes (30tons)m laden.

Horizontally divided tai gates, available for both th insulated and the standar bodies, allow the discharge c loose cargoes and avoid th probability of obstruction by th resultant pile.

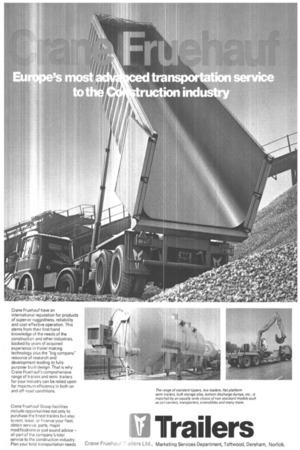

Other extras available, man of them common also to NE ville's many other body type5 include replacement floor we plates, cab protection, exter sions and spill boards. Rep hooks come as a standar fitment on all insulated bodies Crane Fruehauf have an international reputation for products of superior ruggedness, reliability and cost-effective operation. This stems from their first hand knowledge of the needs of the construction and other industries, backed by years of acquired experience in trailer making technology plus the "big company" resource of research and development leading to fully purpose-built design. That is why Crane Fruehauf's comprehensive range of trailers and semi-trailers for your industry can be relied upon for maximum efficiency in both on and off-road conditions.