EDBRO: WE'VE GOT THE GEAR

Page 157

Page 158

Page 159

If you've noticed an error in this article please click here to report it so we can fix it.

Although the Edbro Group is involved in the manufacture of equipment intended for a variety of industries, it is perhaps best known for its range of ancillary gear for the tipper market.

But which gear suits which chassis? What are the do's and don'ts for tipper operators? In How to get the best from your Edbro equipment we have included some advice straight from the horse's mouth.

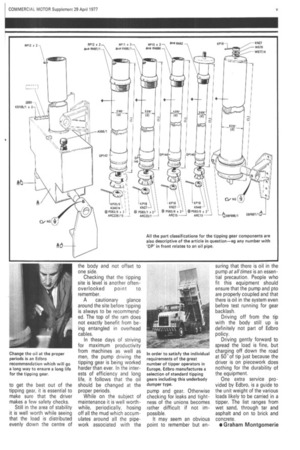

In order to satisfy the individual requirements of the great number of tipper operators in Europe, Edbro manufactures standard tipping gears in the following groups: en from the normal truck gearbox. Where combined units do not suit the individual application, Edbro can supply a range of shaft-drive pto's, drive shafts and separately mounted pumps.

To ensure that the tipper operator gets the right gear for his particular chassis and for the particular load, Edbro distributors have a comprehensive manual listing the various types of tipping gear and relating them to specific body lengths and gross weights. The manual is extremely comprehensive and actually goes into the necessary details for individual models and not just makes, eg Leyland Lynx, Bison, Buffalo and Dodge Commando.

To illustrate how simple the manual is, take the case of the ERF six-wheeler, the 25 G3.

Looking this model up in the manual we find that it is plated for 24 tons gvw and the wheelbase is 4.7m (15ft Sin).

The Edbro recommendation for a single ram is then the SLNCL with the 5LN L if a twin ram is required, both being front end mounted. This gives an inside body length of 6.4m (21 ft) with a 711 mm (28in) cab gap.

In alphabetical order the Edbro tipping gear manual covers trucks from the Bedford CF right through to the Volkswagen LT. It is perhaps unfortunate that the list begins and ends with such lightweight chassis so it is perhaps worth mentioning that the manual also covers such heavy machinery as Foden and MAN eightwheelers !

Thus it is a simple matter for any operator to contact his Edbro distributor and select the correct gear for his specific operation.

The standard angle of tip with Edbro equipment is between 45 and 50 'depending on the chassis model although gears can be provided with ram lifts to give tipping angles of up to 55° depending on application and Edbro engineering department approval.

For certain applications, hoists with angles of tip in excess of 55'can be supplied having power return on the top ram stage.

As far as three-way tippers are concerned, the angle depends on the chassis model but it is normally between 45° and 50° both side and rear. Dumper gears give a 70° tipping angle with power return.

The maximum body lengths listed for the various tipping gears assume an overhang of 457 to 610mm (lft 6in to 2ft) past the rear tipping hinge with the hinge mounted adjacent to the rearspring hanger bracket.

Edbro normally recommends front-mounted single rams, but there is a range of alternatives if the operator wants them. One of the advantages of the single ram is that there is a smaller number of sealing points and hence a small number of potential leak sources.

A recent development in the field of tipping gear was the introduction of the Edbro D-Series. With this type the hydraulic sealing is on the outside of each ram tube. Intended for arduous oper

ating conditions the outside sealing gear is available for lift capacities from 12'1 to 28 tons.

Tipping gear, of course, is not solely for use on rigid vehicles—there is a healthy semi-trailer tipper market too. Although the same basic principles of tipping gear specification apply to both categories, it is worth mentioning a few extra do's and don'ts to get the best out of semi-trailer tipping gear.

Light and free-flowing loads such as bulk grain can usually be cleared at lower angles of tip than is the case with clinging loads such as clay. Thus the stability during tipping can be increased if the maximum angle can be kept down—about 40° should be sufficient.

Tipping with the tractive unit and the trailer out-ofline can cause problems of instability as the fifth-wheel coupling pivots in a fore and aft plane and, the greater the angle between the trailer and unit, the more it can pivot sideways.

As far as the type of tipping gear is concerned, Edbro recommends the frontmounted ram as giving the greatest stability for semitrailer operation.

Whatever precautions are taken by the manufacturers, to get the best out of the tipping gear, it is essential to make sure that the driver makes a few safety checks.

Still in the area of stability it is well worth while seeing that the load is distributed evenly down the centre of the body and not offset to one side.

Checking that the tipping site is level is another often overlooked point to remember.

A cautionary glance around the site before tipping is always to be recommended. The top of the ram does not exactly benefit from being entangled in overhead cables.

In these days of striving for maximum productivity from machines as well as men, the pump driving the tipping gear is being worked harder than ever. In the interests of efficiency and long life, it follows that the oil should be changed at the proper periods.

While on the subject of maintenance it is well worthwhile, periodically, hosing off all the mud which accumulates around all the pipework associated with the pump and gear. Otherwise checking for leaks and tightness of the unions becomes rather difficult if not impossible.

It may seem an obvious point to remember but en

suring that there is oil in the pump at all times is an essential precaution. People who fit this equipment should ensure that the pump and pto are properly coupled and that there is oil in the system even before test running for gear backlash.

Driving off from the tip with the body still up is definitely not part of Edbro policy.

Driving gently forward to spread the load is fine, but charging off down the road at 50° of tip just because the driver is on piecework does nothing for the durability of the equipment.

One extra service provided by Edbro, is a guide to the unit weight of the various loads likely to be carried in a tipper. The list ranges from wet sand, through tar and asphalt and on to brick and concrete.

• Graham Montgomerie