WORKSHOP AND GARAGE HINTS.

Page 61

If you've noticed an error in this article please click here to report it so we can fix it.

Some Useful Contributions From Our Driver and Mechanic Readers.

-Casting New Pistons.

MHERE are cases in which new pistons may be required, and where they cannot for some reason be procured from the makers. In instancea such as this a garage mechanic has to do the best he can by improvising a pattern and relying on a local foundry. To make a pattern is a simple matter so long as sufficient metal is allowed for machining, but the difficulty most of those who have tried to make new pistons have come up against lies in the core-box. To have a new core-box made is not only expensive, but it requires the services of a good pattern maker, which are not always available.

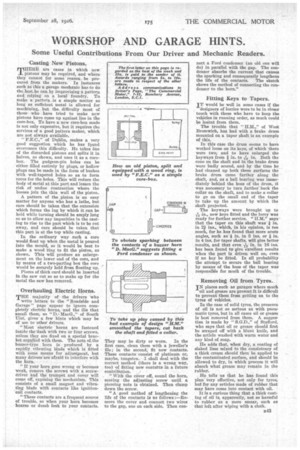

" F.E.C.," of Dublin, makes a very good suggestion which he has found overcomes this difficulty. He takes one of the discarded pistons and splits it in halves, as shown, and uses it as a corebox. The gudgeon-pin holes can be either filled entirely by plugs, or hollow plugs can be made in the form of bushes with well-tapered holes so as to form cores for the holes. This will reduce the body of metal at this part and lessen the risk of undue contraction where the bosses join the thin wall of the piston.

A pattern of the piston is an easy matter for anyone who has a lathe, but care should be taken that the extension which forms the lug by which it can be held while turning should be amply long so as to allow any impurities in the casting to rise to the part which is to be cut away, and care should be taken that this part is at the top while casting.

In the ordinary way such a core would float up when the metal is poured into the mould, so it would be best to make a wood ring to fit the piston, as shown. This will produce an enlargement on the lower end of the core, and by means of a two-parting box the core would be securely held from floating up.

Pieces of thick card should be inserted in the saw cut so as to make up for the metal the saw has removed.

Overhauling Electric Horns.

THE majority of the drivers who write letters to the "Roadside and Garage" page appear to ignore completely electric horns, and the ills that assail them, so "D. MacG. " of South Uist, gives a few hints which may be of use to other drivers.

"Most electric horns are fastened inside the dash with two or four screws, unless they are fixed on a special bracket supplied with them. The note ot the buzzer-type horn is produced by a rapidly vibrating blade which is fitted with some means for adjustment, but many drivers are afraid to interfere with the horn.

"If your horn goes wrong or becomes weak, remove the screws with a screwdriver and the trumpet and cover will come off, exposing the mechanism. This consists of a small magnet and vibrating blade with contacts like ignition-coil contacts.

"These contacts are a frequent source of trouble, so when your horn becomes hoarse or dumb look to your contacts.

They may be dirty or worn. In the first ease, clean them with a jeweller's file; in the second, fit new contacts. These contacts consist of platinum or, maybe, tungsten. I shall deal with the correct method (there is a wrong way, too) of fitting new contatts in a future contribution.

". With the cover off, sound the horn, moving the adjusting screw until a piercing note is obtained. Then clamp down the screw.

"A good method of lengthening the life of the contacts is as follows :—Remove the cover and connect two wires to the gap, one on each side. Then con nect a Ford condenser (an old one will do) in parallel with the gap. The condenser absorbs the current that causes the sparking and consequently lengthens the life of the contacts. The sketch shows the method of connecting the condenser to the horn."

Fitting Keys to Tapers.

IT would be well in some cases if the

designers of lorries were to be in closer touch with those who have to keep the vehicles in running order, as much could • be learnt from them.

The trouble that " H.M.," of West Bromwich, has had with a brake drum mounted on a taper shaft is an example of this.

In this case the drum seems to have worked loose on its keys, of which there were two, and to have enlarged the keyways from in. to it, in. Both the

i cone on the shaft and n the brake drum were badly scored, and by the time he had cleaned up both these surfaces the brake drum came farther along the shaft, and, as a ball bearing was immediately behind the boss of the drum, it was necessary to turn farther back the collar on the shaft, and to make a collar to go on the small end of the taper to take up the amount by which the shaft projected.

The keyways were brought up to

in., new keys fitted and the lorry was ready for further service. " H.M." says that the taper on this shaft was lc in. in n ins., which, in his opinion, is too much, for he has found that more acute angles, such as in, in 3 ins, or in. In 4 ins, for taper shafts, will give better results, and that even in. in 16 ins. has been found to give excellent results when the part is driven well on, even if no key be fitted. In all probability the attempt to secure the ball bearing by means of the boss of the taper was responsible for much of the trouble.

Removing Oil from Tyres.

IN places such as garages where much oil and grease are present it is difficult to prevent them from getting on to the tyres of vehicles.

In the case of solid tyres, the presence of oil is not so serious as with pneumatic tyres, but in all cases oil or grease is beat removed from them. A sugg,esthin is made by " S.G.D.," of Stafford, who says that oil or grease should first be scraped off with a blunt knife, and the article washed with warm water and any kind of soap.

He adds that, when dry, a coating of slaked lime mixed to the consistency of a thick cream should then be applied to the contaminated surface, and should he allowed to dry, in which process it will absorb what grease may remain in the rubber.

He tells us that he has found this plan very effective, not only for tyres, but for any articles made of rubber that may have come into contact with oil.

It is a curious thing that a thick coating of oil is, apparently, not so harmful to rubber as a mere smear, such as that left after wiping with a cloth.