SPEEDY REPAIR OF STEAM WAGON BOILERS.

Page 60

If you've noticed an error in this article please click here to report it so we can fix it.

The Arrangements Made by a Well-known Company to Ensure that the Organization of Transport Owners_ Does Not Suffer by Prolonged Delay.

THE task of effecting running repairs and adjustments to the average petrol vehicle is one which can mostly be performed without the need for highly specialized knowledge, and is often within the compass of the experienced driver. The number of engineering establishments which is prepared to undertake the overhaul and repair of any make or type of petrol vehicle, although not in a position to carry out similar work on different types of steam wagon, is sufficient proof of the fact that the average mechanic is better equipped to undertake work on vehicles of the petrol type than on those of the latter class. Repairs to steam wagons and locomotive boilers are of a highly specialized character, and the very nature of the work demands spacious Premises equipped with adequate plant and tools which enable this class of heavy work to be efficiently carried out.

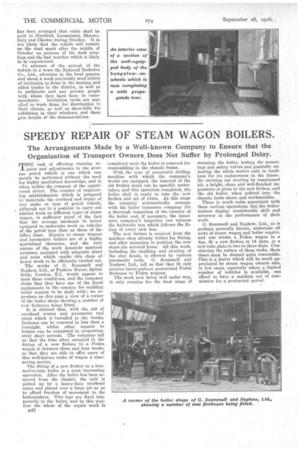

The works of G. Scammell and Nephew, Ltd., at Fashion Street, Spitalfields, London, E.1, would appear to meet these conditions, and the company claim that they have one of the finest equipments in the country for enabling boiler repairs to be dealt with ; we reproduce on this page a view of a corner of the boiler shops showing a number of new fireboxes being fitted.

It is claimed that, with the aid of overhead cranes and pneumatic tool plant which is installed in the works, fireboxes can be renewed in less than a fortnight, whilst other repairs to boilers can be completed in proportionately short periods. The company tell us that the time often occupied in the fitting of a new firebox to a Foden wagon is between three and four weeks, so that they are able to offer users of this well-known make of wagon a timesaving service.

The fitting of ,a new firebox to a locomotive-type boiler is a most interesting operation. After the boiler has been removed from the chassis, the unit is picked up by a heavy-duty overhead crane and placed over a large pit so as to afford freedom of movement to the boilermakers. Two legs are fixed temporarily to the boiler, and in this position the whole of the repair work Is B42 completed until the boiler is removed for reassembling in the chassis frame.

• With the type of pneumatic drilling ;nachine with which the company's works are equipped, the removal of the old firebox stays can be speedily undertaken, and this operation completed, the boiler shell is ready to take the new firebox and set of tubes. At this stage the company automatically arrange with the boiler insurance company for a thorough inspection of the interior of the boiler and, if necessary, the insurance company's inspector can witness the hydraulic test which follows the fitting of every new box.

The new firebox is received from the machine shop already drilled for fitting, and after mounting in position the new stays are screwed borne. All this work, including the caulking and riveting of the stay heads, is effected by various pneumatic tools. G. Scammell and Nephew, Ltd., tell us that they fit only genuine latest-pattern guaranteed Foden fireboxes to Foden wagons.

The work now being well under way, it only remains for the final stage of steaming the boiler, testing the mountings and safety valves and generally adjusting the whole motive unit in readiness for its replacement in the frame. By carrying out riveting by compressed air, a bright, clean and well-finished appearance is given to the new firebox, and the old boiler, when refitted into the chassis, looks smart and workmanlike.

There is much noiSe associated with these various operations, but the boilermakers display considerable skill and accuracy in the performance of their work.

G. Scammell and Nephew, Ltd. as is perhaps generally known, tindertLe all sorts of steam wagon and boiler repairs. and can retube a Foden wagon in a day, fit a new firebox in 14 days, or a new tube plate in two to three days. Considering the nature of these tasks, these times must be deemed quite reasonable. This is a factor which will be much appreciated by steam wagon owners who, in few cases, especially where a limited number of vehicles is available, can afford to have a machine out of commission for a protracted period.