MORE NEW MODELS FOR THE SHOW.

Page 20

Page 21

Page 22

Page 23

Page 24

Page 26

Page 27

Page 28

Page 29

Page 30

Page 32

Page 33

If you've noticed an error in this article please click here to report it so we can fix it.

A Further Description of Some of the Commercial Chassis to be Shown at Olympia Next Month.

Guys for Next Year.

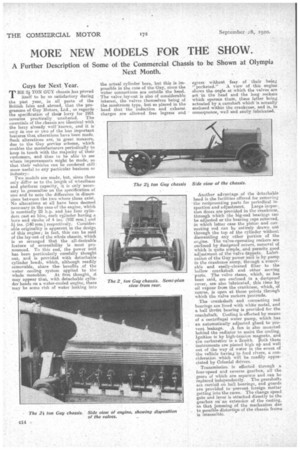

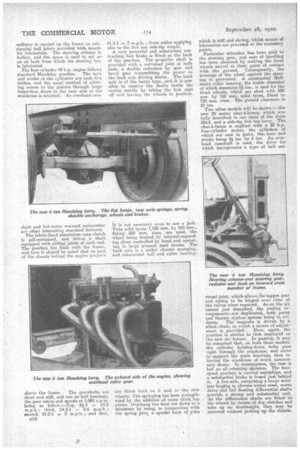

THE 2i TON GUY chassis has proved itself to be so satisfactory during the past year,. in all parts a the British Isles and abroad, that the programme of Guy Motors, Ltd., as regards the specifidation of their lorry for 1921 remains practically unaltered. The essentials of the chassis are identical with the lorry already welt-known, and it is only in one or two 9f the less important features that alterations have been made. Such alterations are, in great measure, due to the Guy aervic,e scheme, which enables the manufacturers periodically to keep in touch with the majority of their customers, and .thus to be able to see where improvements might be made, so that their vehicles can be rendered still • more useful to any particular business or industry.,

Two .models are made, but, since these only differ as to the length of wheelbase and platform capacity, it is only necessary to generalize on the specification of one and to note the difference in dimensions between the two where these exist. No alterations at all have been deemed necereary in the case of the engine, which is nominally 25 h.p. and has four cylinders cast en bloc, each cylinder having a bore and stroke of 4 ins. (102 mm.) and

ins. (140 ram.) respectively. Considerable originality is apparent in the design of this engine; in feet, this can be said of the lay-out of the whole chassis, which is so arranged that the all-desirable feature of accessibility is most pronounced. To this end, the power unit has been particularly carefully thought out, and is provided with detachable cylinder heads, Which, although readily removable, share the, benents of the water cooling system applied to the

whole monobloc. At first thought, it may appear that, with detachable cylinder heads on a water-cooled engine, there may he some risk of water leaking into the actual cylinder bore, but this is impossible in the case of the Guy, since the water connections are outside the head. The valve lay-out is also of considerable interest, the valves themselves being of the mushroom type, but so placed in the bead that the induction and exhaust charges are allowed free ingress and egresswithout fear of their being

"pocketed." A view of this engine 6hOWS the angle at which the valves are set in the head and the long rockers which operate them, these latter being actuated by a camshaft which-. is actually enclosed within the crankcase, and is, in consequence, well and easily lubricated.

Another advantage of the detachable head is the facilities offered for removing the reciprocating parts for periodical inspection and adjustment. Large inspection doors are provided in the crankcase, through which the big-end bearings can be adjusted or the bearing caps removed, in which latter case the piston and connecting rod can be entirely drawn out through the top of the cylinder without dismantling any other portion of the engine. The valve-operating rockers are enclosed by dustproof covers, removal of which is quite simple, and permits good adjustment of the valve tappets. Lubri• cation of the Gary power unit is by pump in the crankcase sump, through a removable and easily-cleaned filter to the hollow crankshaft and other moving parts. The valve stems, which, as has been said, are enclosed in a dustproof • cover, are also lubricated, this time by oil vapour from the crankcase, which, or course, is open at those points through which the valve rockers protrude.

The crankshaft and connecting rod bearings arc lined with white metal, and a ball thrust bearing is provided for the crankshaft. Cooling is effected by means of a centrifugal water pump, which has an automatically adjusted gland to prevent leakage. A fan is also mounted behind the radiator to assist the cooling. Ignition is by high-tension magneto, and the carburetter is a Zenith. Both these instruments are placed high up and well out of the way of water in the event of the vehicle having to ford rivers, a consideration which will be readily appreciated by Colonial drivers.

Transmission is effected through a four-speed and reverse gearbox, all the gears of which are separate arid can be replaced independently. The gearshafts are carried on ball bearings, and guards are provided to •prevent foreign matter getting into the races. The change speed gate and lever is attached directly to the gearbox on an extension of the casting, so that jamming of the mechanism due to possible•distortion of the chassis frame is impossible. The power unit, complete with the forward transmission unit, viz., clutch, front universal joint, gearbox, and gear lever;is carried on a sub frame suspended from the main frame by three universal

joints. This arrangement (which, incidentally, is patented) has been, in the past, and. still is, one of the most interesting and commendable feature a of the Guy lorry, since, in the event Of the distortion of the main frame due to varylag loads or uneven roads, the alignment .cf the crankshaft and propeller shaft remains unbrokiii. This advantage, although very considerable, is not the only one which this method of construeton provides, as, in the event of an accident necessitating the removal of the power and transmission units, this operation can easily be effected by detaching the three universal joints and lowering the sub frame to the groisnd, with the engine and gearbox in their normal posi tion,actual experiment carried out by us at the Guy \Voi'he proved to us that it is possible to raise one of the front road wheels to "an' elevation" 2 ft. greater than the other without throwing the sub frame out of its true alignment.

From the 'gearbox rearwards transmis"sion is by means of an uncovered propeller shaft to the back axle, which is of the double-Deduction bevel and spur'wheel type. The weight ..of the vehicle is taken by the axle case and wheel tubes, and any distortion is not transmitted to the axle Shafts. Provision is made so that bevel and spur gears can be meshed independently, and the lubrication of the back axle is by oil, which is automatis cally fed to gears, differential, road wheels, 'and rear universal joints. Both main and sub frame are of deep section channel sled.

The front axle is an H sectien. The swivel pins have renewable bushes, and the wear on the rods is taken on thrust bearings. Both brakes are of the internalexpanding type, the one operated by foot. being on the bevel pinion shaft on the back axle, in which position none of the braking Strain is transmitted to the pro peiler shaft or universal joints). An interesting point in connection. with this brake is the compression spring device which is provided in the brake operating gear, and which, ensures that only the

• d-esired maximum pressure Can be applled, thus preventing a bad driver from damaging tyres through too severe

• application. The hand brake operates on the rear whee.'s, and both brakes have each half of the brake shoe compensated by an easily replaced sliding cam, to ensure equal' application all round, and to provide for unequal wear or unequal thickness of the liner in the event of renewal.

Suspension is by means of semi-ellipHeal springs all round, the -rear springs being imelershing, and so designed that they take the driving torque. This underslinging also gives the advantage of a -lbw loading platform, which is, of course, ' of considerable value in the case of chars4-bancs.

In accordance with -the policy of Guy Motors, to design their lorry to provide the maximum of accessibility and the minimum of upkeep troubles, the question of the lubrication of the chassis parts has received due consideration. " For instance, front and rear, universal joints axe automatically .lubricated, and pro-

sided with oil-tight joints. The back axle is so designed that oil is Conducted' from the reduction gears along the axle shafts themselves to the wheel bearings. The swivel pins and front road wheel bearings are lubricated from one reservoir -on top of the axle swivels, and the disposition of all the greasers and wick oilers throughout the chassis is so arranged that there is no need to get under the vehicle to lubricate any part.

The steering is of the Worm type, but, instead of using a sector of a wheel, a cornplete worm wheel is employed, and

the lever arranged to fits if necessary.; in four positions ; which means that, when the wheel shows any sign of wear, it can he turned 90 degrees on each of three occasions, and a fresh segment used before replacenient becomes necessary. •

At tbe commencement of this article we explained that the only difference in the two models made is in. the leading dimensions, which are as follow:— Short Wheelbase Chassis.

Ft. Ins.

Wheelbase -... ... 12 Dash to end of platform 12 8i Dash to rear axle centre 9 3i Lung Wheelbase Chassis.

I Wheelbase 411.

Dash to end of platform ... 18 84 Dash to rear axle centre ... 11. 3i One of each of these chassis is to be sent to the Olympia Show, the long wheelbase model being fitted with -a 30seater char-a-banes body, and the short wheelbase model with a 2,1 ton tipping wagon.

In view of the widespread interest in road haulage at the present time we were interested, at the time of our visit to the Guy works, to study 'an unsolicited teSti. reonial which they had just received from the traffic superintendent of one of the leadingrailway companies, in which he-stated that one of these vehicles, which they had been putting through several severe tests, had, over a week's running, covered 16-miles per gallon of

etrol, and that, although no oil had en supplied to the engine during the week, the level still -showed at the high mark at the completion of the tests.

New Maudslay _Six-Tonner.

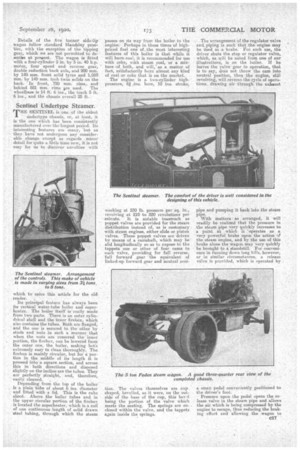

THE NEW MAUDSLAY six-tonnes is designed with a view to providing the maaimum of space behind the. driver. With this in view, the driver and his

• mate are accommodated one on either side -of the engine, the steering box and columns are 'brought well forward, and the radiator forms the central portion of the pressed metal dashboard. The available platform space behind the driver is thus increased to 21 ft. 6 ins, on a wheelbase of 15 ft. 6 ins.

The driver naturally sits on the right side of the /stator, supported by means of strong angle brackets fastened to the frame. Ofi his left side the gate change speed and hand-brake levers are fitted, the squared metal shafts operating the selector mechanism being carried in brass boxes clipped to the off-side member of the frame. The three control 'pedals, accelerator, brake, and clutch are adjustable for. angle, -the first-named being

• provided with a stop The steering column is a substantial job,' and the, steers ing box is provided with extra long Plain bearings and a large-size Hoffmann thrust bearing. All joints are ground, in order to prevent leakage of oil. The back of the driver is situated approximately in line with the flywheel, whilst the selector box for the change speedgear is positioned just behind the front axle. ' The engine and gearbox are carried on a sub frame which terminates just behind the gearbox. The main side members of the frame are made Of straight-rolled channel steel 26 ft. long, and are braced together at intervals by six wrought steel crass tubes. There are no rivets in the frarne, the. whole of the detail work being welithanght out. For instance, in order to obviate the need for long lengths of sagging contaol'rods,, .fan. levers are in terposecl, and the length of brake control "rsids is thus considerably reduced. The turn buckle joints for adjusting these rods are easily accessible, whilst another small detail worth noting is that the radiator is carried on the frame on substantial ball joints provided with means for lubrication. The steering column is hollow' and the space is used to act as an oil tank from which the steering box is lubricated.

The four-cylinder 40 h.p. engine follows standard Maudslay practice. The bore and stroke of the cylinders are each five inches, and the usual method of allowing aecess to the pistons through large inspection doors in the near side of the crankcase is retained. An overhead cam shaft and hot-water warmed carburetter are other interesting standard features.

The fabric-lined aluminium cone clutch is sell-contained, and drives -A shaft equipped with sliding joints at each end. The gearbox lies flush with the frame, iind here it should be noted that no part of the chassis behind the engine projects • above the frame. The gearahafts are short and stiff, and run on ball bearings, the gear ratios and speeds at 1,000 r.p.m. being as follow :—Top, .8A-1 = 14.9 m.p.h.; third, 14.3-1 = 8.6 m.p.h. ; second, 24.2-1 = 5 m.p.h. ; and first,

c16 41.3-1= 3 mph.; these ratios applying also to the five ton. aide-tip wagon. A very powerful and substantial contracting foot brake is fitted at. the back of the gearbox. The propeller shaft is provided with a universal joint at both ends, a double reduction by spur and bevel gear transmitting the power to the back axle driving shafts.. The back axle is of the banjo type, and it is peasible to remove the ahafta inside the casing merely by taking the hub caps off and leaving the wheels in Positien.

It is not necessary even to use a jack. Twin solid tyres, 1,030 mm. by 160 mm., fitting 820 mm. rims, are used, the wheel being braked by internal-expanding shoes controlled by hand and operating in large pressed steel drums. The back axle is a nickel chrome stamping, and substantial ban" and roller bearings

are fitted both to it and to the rear wheels. The springing has been strengthened by the addition of extra thick, top plates. Overhang has been cut down to a minimum by using, in conjunction with the spring pins, a special form of yoke which is stiff and strong, whilst means of lubrication are provided at the necessary ppints.

Particular attention has been paid to the steering gear, and ease of handling has been obtained by making the front wheels swivel at their point of contact with the ground. Consequently, the leverage of the wheel against the steering is prevented. A substantial Hoffmann roller bearing, the inside diameter' of which measures biins., is used for the front wheels, which are shod with 920 mm. by 160 mm. solid tyres, fitted to 720 ram. rims. The ground clearance is 10 ins.

Two other models will be shown :—the new 28 seater charbancs, which was fully described in our issue of the June 22nd, and a side-tip five ton lorry. The char4bancs is engined with a 32 h.p. four-cylinder motor, the cylinders of which are cast in pairs, the, bore and stroke being 44 ins. by 5 ins. An overhead camshaft is used, the drive for which incorporates a type of ball uni versal joint, which allows the tappet gear and casing to be hinged over clear of the valves when required. As on the six tomer just described, the waling arrangements,are duplicated, both pump and thermo syphon system being in evidence. The magneto is driven by a ailent chain, in which a means of adjust ment is provided. Here, again, the practice is similar to that employed on the new six tonner. In passing, it may be remarked that, on both these models, the cylinder holding-down bolts pass right through the crankoaae, and serve to support the main bearings, thus, relieving the crankcase of much unnecessary strain. In consequence, the iase is but an oil-retaining skeleton. The fourspeed gearbox is carried amidships, and a substantial brake is forind just behind it. A live axle, comprising a banjo weldless forging in chrome nickel steel, worm drive and full floating differential shafts provide a strong and substantial unit. As the differential shafts are fitted to the wheels by means of dog clutches and take up no deadweight., they may be removed without jacking up the chassis.

Details of the fiVe tonner side-tip wagon follow standard Mandslay practice, with the exception of the tipping gear, which we are not permitted to describe at present. The wagon is fitted with a four-cylinder 5-in, by 5 in. 40 h.p. motor, four speed and reversegear, double reduction hack axle, and 900 mm. by 140, ram. front solid tyres and 1,050 non. by 140 mm. inch twin solids on the back. In front, 720 mm. rims,, and

behind 801 inm, rims ere used. The wheelbase is 14 ft. 6 ins., the track 5 ft. 6 ins.„ and the chassis overall 25 ft.,

Sentinel Undertype Steamer.

THE SENTINEL' is one. of the oldest a " rindertype chassis, or, at least, it is. the one which has been consistently manufactured over thelongest period: Its interesting features are many, but as they have not undergone any considerable .change except as regards minor -detail for quite a little time now, it: is not easy -for us to discover novelties with

which to spice this article for the old reader. .

Its principal feature has always been its vertical water-tube boiler and superheater. The boiler itself is-really made from two parts. There is an outer cylindrical shell and the inner firebox, which also contains the tubes. Both are flanged, and the one is secured to the other by studs and nuts in such a manner that when the nuts are removed the inner portion, the firebox, can be lowered frorn the outer one, the boiler, making both extremely easy to clean thoroughly. The firebox is mainly circular, but for a portion in the middle of its length it is pressed into a square section, and across. this in both directions and disposed slightly on the incline are the tubes. They are perfectly straight, and, therefore, easily cleaned.

Depending from the (Op of the boiler is a plain tube of about 6 ins., diameter and fitted with a lid. This is the coke shoot.. Above the boiler tubes and in the upper circular portion of the. firebox is located the superheater, which is 4 coil of one continuous length of solid drawn steel tubing, through which the steam

passes on its way 'from the boiler to the engine.' Perhaps in these times of highpriced fuel one of the most interesting features of this boiler is that while it will burn.coal, it is recommended for usa with coke, with steam coal, or a mixture ,of, both, and will,' as a matter of fact, satisfactorily burn almost any kind of coal or coke that is on the market.

The engine is a two-cylinder highpressure, 6t ins. bore, 10 ins. stroke,

-Working at 230 lb: pressure per sq. in., revolving at 210 to 220 revolutions per minute. It is notable inasmuch as poppet. valves are provided for the steam distribution instead of, as is customary with steam engines, either slide or piston valves. These poppet valves are driven by means of a camshaft, which may be slid longitudinally so as to expose to the tappets one or other of four cams to each valve, providing for full reverse, full forward gear the equivalent of linked-up forward gear and 'neutral psi

lion. The valves themselves are cup shaped, bevelled, as. it were, on the outside of the base of the cup, this hev4 being the portion of the valve which meets the seating. The springs are en. closed within the valve, and the tappets again inside the springs.

The arrangement of the regulator valve andepiping is such that the• engine may he used as a brake. For, such use, the driver shuts the stop or regulator valve, which, as will be noted from, one of our illustrations, is on the boiler. If he leaves the valve 'gear in operation, that is to say, doe's not throw the cam into neutral position, then the engine, still revolving, will reverse the cycle of operations, drawing air through the exhaust

pipe and pumping it back into the steam pipe.

With matters so arranged, it will readily be realized that the pressure in the steam pipe very quickly increases to a . point at which it 'operates as a very powerfulbrake upon the action of the steam engine, and by the use of this brake alone the wagonmay very quickly be brought to a standstill. For convenience in funning down long hills, hoWever, or in similar circumstances, a release valve is provided, which. is operated by

a. small pedal conveniently positioned to the driver's foot.

Pressure upon the pedal opens the release valve in the steam pipe and allows the air which is being compressed by the engine to escape, thus reducing the braking effort and allowing the wagon to free wheel. Complete control of the speed of the wagon on the steepest hill may be accomplished by intelligent use of this apparatus.

There is no change-speed gear on the Sentinel. The engine drives direct to the differential gear on the rear axle through a stout roller chain, and a second brake takes, the form of a substantial brake drum mounted on the differential. case. Sentinel wagons are made in

Various sizes for general use, carrying leads of from 31 to 6 tons. They are also at the present time turning out a considerable number of wagons specially made for use in Liverpool, where the regulations allow the use of an fatonner.

. The Foclen Steam Wagons. TT IS RATHER a matter of doubt as I to whether the Foden was the first over-type steam wagon, nor have we, in the present instance, space in which to discuss this important historical matter. We believe we are quite safe, however, in -stating that this make of wagon Was the first steam vehicle to appear, haying the general characteristics which still appertain to it. This-is true to such an extent that "Foden-type wagon" is a commonly used expression in the trade. There is nothing extremely involved about the construction, which clearly grew out of the old traction engine design, the engine and boiler of that well known vehicle being condensed, so to speak, and the frame lengthened to the rear inorder to accommodate a load-carrying body. It is interesting to note that, so closely was the type copied by other makers that a certain temporary expedient in connection with early Foden wagons, that of extending the frame by means of timber fitted into the rear end tif, the existing channels, was copied together with the other features.

Since the Foden is a type, it is aa well for the benefit of new readers to describe it as such. The source of power is a locomotive type boiler, which consists of a firebox at the rear, mainly square, and a barrel-like boiler, • within which is a. number of tubes running the full length

-of this barrelled portion. These tubes convey the hot gases from the fire through the water, emerging at the front end in a smoke-box and passing thence thaough the chimney. The same design of boiler, almost without exception, is used on locomotive engines throughout the world, hence its title.

Mounted on a platform, or platforms, on the top of the boiler is the engine, a two-cylinder compound, in which, in normal eircum4tances, the steam from the boiler passes first to high pressure, the smaller of the two, where it expands, pushing the piston before it, and, when exhausted, passes to the low pressure cylinder, somewhat larger in size than the other, where it again expands, doing more useful work, and is finally turned into the atmosphere through a pipe . which is directed up the chimney, so that the exhaust steam induces an increased draught through the firebox, tubes, etc.. of theboiler. On the end of the crankshaft are mounted a pair of gearwheels, which may be slid to and fro. The lever controlling these wheels has three positions. In one, the mid one, the gears on the crankshaft are free. There is a countershaft supported on the frame of the chassis, and on this counter. shaft are two large gearwheels, of such a size that each may suitably be engaged with a corresponding pinion on the crankshaft, thus providing two speeds. A rprocket pinion is mounted on the eorin

C18 tershaft, and the final, drive to the differential gear on the rear axle is by a substantial roller chain.

" The rear axle itself still, persists, with very little modification, in its a traction engine form.. A substantial bar runs through from one road wheel to the other, being keyed to one of ttem. One of the sun wheels of the differential gear is also keyed to this bar ; the other is fastened to a sle_eve, which rides upon the bar and is _attached to the other road

wheel. Provision is usually mide for locking the bar to the sleeve by meansof a substantial pin, so that, temporarily, the differential may be put out of action.

The front axle is, as a rule, and certainly on the Foden, centrally pivoted; _ that is to say, the steering gear is not of the type familiar on motorcars and petrol lorries, and coin/holy known as the

Ackerman. There are no short stub axles for each wheel, but, instead, the front axle itself is in one piece from end to end, and supports at its centre by means of a vertical pin and seat the

'front end of the wagon. A one-piece chain, or its equivalent, is attached at its ends near to tire ends of the axle, and the chain itself is wound round a drum which is revolved by means of the steering gear, thus swivelling the front axle about its central pivot. It is a curious fact that, notwithstanding occasional divergence from this praatiee, a central pivot axle is still most popular for the avert,ype steara wagon.

In the foregoing, we have briefly delineated that type of steam vehicle' of which the Foden was practically the original, and in so doing we have, to all practical intents and purposes, described the present-day Foden steam wagon itself, far, apart from improvements in detail which have suggested themselves from time to time, the design of the Foden has not altered for some years_ So successful has it been that the makers, although at one time considerable mania facturera of various classes of agricultural machinery, including threshing machines, traction engines, etc., have, one by one, abandoned these for other interests until, at the present time, the works are solely concentrated on the manufacture of steam wagons, which they make in two types for nett useful loads of 3 and 5 . tons respectively. Between these two types, such difference.s only are made as would naturally be expected; that is to say, the one is a replica of the other, except as regards rear axle strengths, frame and spring weights, and gear ratios. The boiler and engine are standardized throughout. The former provides steamon a working pres sure of 200 lb. to the sq. in. This is utilized by the compound engine having cylinders 4 in. and 61 in. diameter by 7 in. stroke. By means of an ingenious regulator valve, combined with a three-way cock in the exhaustpipe, this engine can be utilized as a double high pressure, the high pressure steam being turned direct into both high and low pressure cylinders instead of only into the one, thus affording increased Power when an unusual demand is encountered; the same device enables the engine to be started, no matter in what position the cranks may have been left. Needless to say. this high pressure working is only to be used occasionally, and is not available for continuous service.

As indicated in our general description, two changes of gear are provided, and these at normal engine speeds provide for speeds of 4 to 8 nriles per hour. The engine itself, of course, is designed to revolve in either direetien, so that these speeds are available for forward and reverse.

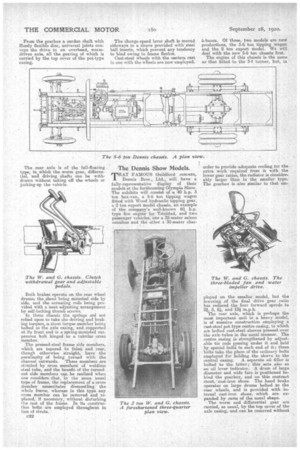

One pedal-operated brake, properly compensated, and providing ample leverage, takes effect on drums on the . rear wheels. The engine itself serves as a second brake. The water tank has a capacity of about 150 gallons, which is sufficient to enable the wagon, when fully' loaded, to run a distance of 18 to 20 miles on good roads before calling for a further. supply. The coal bunkers carry-sufficient fuel for a journey of double that distance. More fuel can, of course, be carried on the wagon. The water feed to the boiler is as is usual, duplicated, an injector and pump being provided for the purpose. Attention should be called to the mechanism for driving the latter. It is effected by an arrangement of friction wheels, which are only brought into engagement at 'the will of the driver, so that there is no need for the pump to be running except when there is a demand for water. Incidentally, friction gear is much quieter than spurwheels.

In making our examination of tile wagon which is to be _exhibited at Olympia we noticed, -With particular interest, certain peculiarities in the design of this machine, and in particular certain features which have persisted for long periods, to such an extent that they might now, by the superficial observer, be declared as old fashioned. Space forbids a general consideration of these points, but we would like just to mention one typical example. The sliding pinions on the crankshaft are driven through four keys, each of which is dovetailed into the shaft.In these days, when the splined shaft is such a universal fitting, one naturally wonders why this somewhat old-fashioned method is still persisted in. The answer is a simple one. The. keys take a drive. They are also, as Clete goes on, worn by the sliding to and fro of the pinions, and when that time comes it is a simple matter to replace the keys, whereas it would be anything but econoinical to have to fit a new crankshaft, which might be necessary had splines been used.

The Robey Steam Wagon. The Robey Steam Wagon.

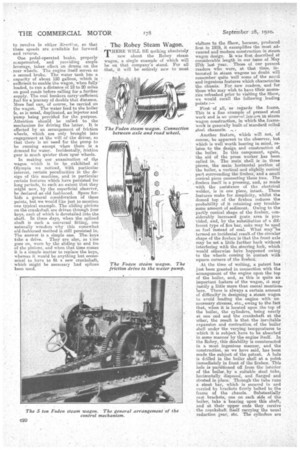

THERE WILL BE nothing absolutely new about the Robey steam wagon, a single example of which will be on that company's stand. For all that, it will be entirely new to most

visitors to the Show, because produced first in 1919, it exemplifies the most ad vanced and modern construction in steam wagon design. It was first described at considerable length in our issue of May 27th last year. Those of our present readers who were, at that time, interested in steam wagons no doubt will remember quite well some of the novel and ingenious features which characterize the chassis. For new readers, and for those who may wish to have their memories refreshed prior to visiting the Show, we would recall the following leading points :— First of all, as regards the frame. This is a fine example of pressed steel

work and is an -unusual reateres in steam wagon construction, in which the framework is generally built of standard rolled steel. channels. ,..,

Another feature, which will not, of course, be apparent to the observer, but which is well worth bearing in mind, relates to the design and construction of the bailer. In this component, again, the aid of the press worker has been called in. The main shell is in three pieces, the main horizontal portion of: the boiler, a vertical and slightly conical part surrounding the firebox, and a small conical piece connecting these two. The , firebox itself is a pressing, and, as made with the assistance of the electrical welder, is in one piece, intact. These features make for simplicity, whilst the domed top of the firebox reduces the probability of it retaining any trouble some amount of sediment. Owing to the partly conical shape of the firebox, con siderably increased grate area is pro vided, and, by the substitution of a dif; ferent type of fire bar, coke may be used as fuel instead of coal. What maybe termed an incidental result of the circular shape of the firebox is that the front axle may be set a little further back without.' interfering with the steering lock, which would otherwise haVe happened owing. to the wheels coming in contact with square corners of the firebox.

At the time of writing, a patent has just been granted in connection with the

arrangement of the engine upon the top of the boiler, and, as this is quite an important feature of the wagon, it may justify a little more than casual mentions. here. There is always a certain amount of difficulty` in designing a steam wagon to avoid loading the engine with un.

necessary streeses, etc. owing to the fact that, when it is located upon the top of the boiler, the cylindere, being nearly at one and and the crankshaft at the other, the result is that the inevitable expansion and contraction of the boiler shell under the varying temperatures to which it is subject have to be absorbed in some manner by the engine itself. Li the Robey, this disability is counteracted in a most ingenious manner, and the construction, as we have said, has been made the subject of the patent. A hole is deified in the boiler shell at a point

immediately in front of the firebox. This hole is partitioned off from the interior of the bailor, by a suitable steel tube, horizontally disposed, and flanged and riveted in place. Through the tube runs a stout bar, which is secured in and carried by brackets firmly bolted to the frame of the chassis. Substantially cast brackets, one on each side of the boiler, take a bearing upon this shaft, and at their upper ends they receive the crankshaft itself carrying the usual reduction gear, etc. The cylinders are -mounted, as is customary, on a saddle riveted to the boiler shell, and these brackets on the shaft are rigidly connected to the cylinder castings by means of substantial staples. -Now, it will be realized that, no matter What may be the expansion or contraction of the boiler shell, the distance from cylinders to crankshaft is always deter. mined bY the staples, and the brackets which carry the crankshaft may swivel upon the shaft which runs through the boiler, and thus allow free expansion and contraction:of the boiler without disturbing the arrangement of the engine. The efficiency of this arrangement ie rendered. the more complete by mounting the change-speed gearwheels on the.shaft which runs through the boiler.

Another interesting feature of this wagon is the steering gear. This is a combined bevel gear and warm and sector. The steering column itself carries a bevel wheel, which engages with another -mounted on a horizontal crossshaft in front of the axle. On this crossshaft in a worm, ediaging with a worm wheel mounted on the pivot itself. It Will be understood, therefore; that any mobernent of the steering wheel causes this worm wheel to revolve about the steering pivot. . On this wheel arc mounted arms, which engage through a pair of helical coil springs another arm mounted on the front axle itself, so that, while the more direct effect of worm and .wheel steering, is obtained, there is still left in these springs sufficient elasticity to enable the wagon safely to encounter the rough conditions of usage to which steam wagons are habitually put.

Attention may suitably -Le drawn to the design of the road wheels of this wagon, which are of pressed steel, the _hubs being actually east into the discs. The brake gear is interesting, both on account of the extremely large drums, almost as large CIA the rear wheels themselves, and, also, beeanse the necessity for weight reduction has clearly not been overlooked in so small a detail as this.. since, since, it should be noted that the brake rods themselves are of elliptical steel tubing instead of plain solid rod.

W. 'and G. Show Models.

Pk/DUCTS FROM the well-known W. and G. Du Gros works at Acton have always merited and attained a; considerable amount of popularity amongst users, and the Models which will be exhibited at the Olympia Show should certainly not detract from this popularity.

Four vehicles will be shown, coinpriling two 2-tanners and two 21-tonners. Of the former one will be fitted with a canvas tilt bode, and' the other with a fine 20-seater Aar-a-banes de live body painted green and primrose, and upbol stered in light emerald green • real hide. The waterproof hood will be provided with patent roller fittings, sliding on brass rails fixed to the sides of the body. The char-a-banes-will also be fitted with brass luggage rails on .the backs of the seats, match strikers, umbrella stands. etc., and the wheels will be shod with Giant pneumatic tyres, 40 ins. by 8 ins, at the rear, and 36 ins. by 6 ins. at the front, an air pump for inflating purposes being driven, from the gearbox. Of the 21. ton chassis, one will have a. 11.7.D.-type body, with hinged sides, hoops, and waterproof cover, and the other a steel; end-tipping body provided with hand-operated tipping gear.

The observant will note that the vehicles are classified as '2 ton and 21 ton respectively, instead of '30 cwt. and 2 ten. To enable this to be done the chassis have been strengthened at all important points, the wheelbase is longer, the springs are, of course, stronger, and both chassis are now provided with larger

wheels, these being 720 mm. diameter all round., and shod with tyres of 100 mm. width, single at the front, and twin at the rear. Both models embody the sametype of Dorman engine, specially designed for the company by the makers, and having a-bore and stroke of 95 mm. and 149 rem. reepectively.. This engine is extremely neat, . and yet powerful, developing 33b.h.p. at 1,400 r.p.m. The valves, which are all on one side, are operated by 'a single camshaft driven by a silent chain from the camshaft. A large oil pump, located at the lowest point of the sump, and driven by spiral gearing from the camshaft, delivers oil through the drilled crankshait, the surplus oil from the .pump passing through a relief valve to the timing gear. -Both the carburetter and the magneto are accessibly positioned at the offside of the engine. The water jackets and water pipes have been designed to function, if necessary, on the theimo-syphonic principle, but this is assisted by an impeller driven by the same Whittle belt which drives the fan.

In the case of the heavier model, both the engine and the gearbox are motinted on a rigid sub frame, but in the 2 ton chassis the gearbox is mounted on the three-point suspension principle from a stout tubular cross member at 'the front end, and from steel brackets, bolted to the side members, at the rear. The engine is also carried at four points by ihigh-tensile steel brackets. Another difference between the two is that the laea,vier model has four forward speeds, and the lighter three only. ' So far as the remainder of the chassis is con-corned, apart from the matter of strength, the designs are identical. A cone -clutch of the external type, Ferodo faced, isPprovided. The e'uLehoperating mechanism, which is shown in one of the illustrations which we reproduce, is simple and efficient. Both the brake and clutch pedals can be adjinted to suit the driver* reach. As the clutch pedal is depressed two radial ball races press against a collar on an extension el the clutch. centre, thus withdrawing the clutch; further depression brings into action a neataFerodo faced clutch brake.

Prom the gearbox a cardan shaft with Hardy flexible disc, universal joints conveys the drive to an overhead, wormdriven axle, all the gearing of which is carried by the top cover of the pot-type casing.

The rear axle is of the full-floating type, in which the worm gear, differential, and driving shafts can be withdrawn without taking off the wheels or jacking-up the vehicle.

Both brakes operate on the rear wheel drums; the shoes being Mounted side by side' and the actuating rods being provided with a neat adjusting arrangement by self-locking thumb screws. . In these chassis the springs are" not relied upon to take the driving and braking torques, a stout torque member being bolted to the axle easing, and supported • at its front end is a spieng-mounted suspension bolt hinged to a tubular cross member.

The pressed-steel frame side members, which are tapered to front and rear, though otherwise straight, have the peculiarity of being turned with the channel outwards. These members are strutted by cross members of weldless steel tube, and the benefit of the turnedout side members can be realized when one considers that, in the more usual type of frame, the replacement of a cross member necessitates dismantling the whole frame, whereas in this type any cross member can be removed and replaced, if necessary, without disturbing the rest of the frame. In its construction bolts are employed throughout in lien of rivets.

c22 The change-speed lever shaft is moved sideways in a sleeve provided with' steel ball inserts, which prevent any tendency to bind owing to frame flexion. Cast-steel wheels with the centres cast in one with the wheels are now employed.

.The Dennis Show Models.

THAT FAMOUS Guildford concern, Dennis Bros., Ltd., will have a fully-representative display of their models at the forthcoming Olympia Show. The exhibits will consist of a 40 h.p. 3 ton box-van, a 5-6 ton tipping wagon fitted with Wood hydraulic tippinggear, a 2 ton export model chassis, an example of the company's well-known 60 h.p. type fire engine for Trinidad, and two passenger vehicles, one a 32-seater saloon omnibus and the other a 30-seater char

it-bancs. Of these, two models are new productions, the 5-6t ton, tipping wagon and the 2 ton export Model. We will deal with the new 5-6 ton chassis first.

The engine of this chassis is the same as that fitted to the 3-4 turner, but, in order to provide adequate cooling for the extra work required from it with the lower gear ratios, the radiator is considerably larger than in the smaller type. The gearbox is also similar to that em

ployed on the smaller model, but the lowering of the final drive gear ratio has reduced the four forward speeds to 24, 5, 54, and 13i m.p.h. The rear axle, which is perhaps the most' important unit in a heavy model, is of massive construction employing a cast-steel pot type centre easing, to which are bolted cast-steel sleeves pressed over the axle tubes in the usual manner. The centre easing is strengthened by adjustable tie rods passing under it and held by special bolts to each end of it; these bolts take the place of the ordinary bolts employed for holding the sleeve to • the

central easing. A separate oil filler is bolted to the latter; this acts also as

• an oil lever indicator. A drum of large diameter and wide face is positioned behind the gearbox, and on this contract stout, cast-iron shoes. The hand brake operates on large drums bolted to the rear wheels, and is provided with internal cast-iron shoes which are expanded by cams of the usual shape. The worm and differential gear are carried, as usual, by the top cover of the axle casing, and can be removed without

taking down. the axle, the driving shafts also being removable without jacking up the chassis. Phosphor-bronze floating bushes ate employed on all the wheels, the bearing surfaces . of which are hardened and ground.. • Bolted to the rear axle is a heavy tubular torque member, which, at its frant end, is supported in a massive cross memberTo give universal action, the. front end of the torque member ia made

spherical, and the socket in the cross member is similarly shaped. An interesting point in the design is that this cress member is held in rubber-lined. trunnions at each end, as also is the radiator.

A channel section, pressed steel frame,. considerably heaVier than that employed on the 3-4 ton model, is utilized, and. the springs, of course, are longer and deeper, in order to cope with the extra load.

Dennis Bros., Ltd,, experience 'a big demand for their vehicles front °verse*, and they are catering for this market with their 2 ton overseas Model which has just been produced.

This chassis differs radically in certain of its features' from its predecessors, particularly in regard to the controls, the 'change-speed and hand-brake levers being centrally positioned, and, consequently, operated by the driver's left hand, the change-speed gate and brake sector being carried together on a stout cross member.: The power unit is four-cydindered and • T-headed; the .cylinders being cast in pairs, and. having a bore and stroke of 105 mm. and 150 mm. respectively. Very little can be said of this unit except. that it is of simple construction and. good design, accessibility being one of its chief . features. The valves are enclosed by two plates.

As is 'usual with overseas models, ample mobil, area is provided by the radiator, and the cooling water circulation is by centrifugal pump; the inlet pipe is . hot-water jacketed. A east aluminium boss is employed for the fourbladed fan, but the plates themselves are cut from .sheet aluminium and riveted to the boss.

Three-pointed suspension is employed for the sob-frame on 'which the engine is, mounted, and, unlike the 3-4 tanner, the gearbox is suspended from two arched cross members. instead of being on the sub-frame with the engine. The clutch is of the single-plate type working between Ferodo rings, the clutch withdrawal mechanism being of simple construction and particularly accessible for adjustment. Between the clutch and the .garbox is a clutch shaft provided with somewhat unusual pattern. universal joint, each of which consist of six large steel balls working in sockets in the shaft.

'Four speeds forward and a reverse are provided by the gearbox, the casing of which is an aluminium casting fitted with a large cover, giving the maximum opening. The gearshafts run on ball bearings, and are &Oiled for the gears, which are of chreine nickel steel.

The -back axle itself is a-miniature of those on the larger models, and is also

• worm driven, but in this instance the torque member has been dispensed with. The drive from the gearbox ti) this axle is through a long propeller . shaft and two universal joints of the radial "ball-bearing type, and totally enclosed. This model is made in two wheelbases, viz., 12 ft. for ordinary work and 13 ft. iof chars-ft-banal. We need not go into details hero •regarding the other Models which the company will be showing, as these are so well known in all quarters.

Two Types of Clayton Steamers.

not likely that any stand at

:Olympia will afford more interest, at least to the steam wagon -buyer, than that of Clayton and Slinttleworth, Ltd. Notonly is this cotripany showing an

entirely new model, of a type which to them is quite novel, but on the same stand will be seen two distinct types and designs of steam wagon's. There will be on the one hand the overtype, which has for long been a, form manfa.ctured by this Lincoln concern, and on the other hand the undertYpe, to which this established company have hitherto been entire stranters. •' Considerations of space are rather exigent, and we .eannot, therefore, describe this new model at such length as we would have liked. We may, per haps, save space by eliminating what we may. term a general description, going mm the understanding_ that the reader already understands precisely what is meant by undertype and overtype. Having agreed that, it is only necessary to add, before describing to detail, that as regards the general arrangement, of this new chassis there is nothing new or unusual. In details, however, the reverse is true.

We may commence a brief review of theae navel details by a reference to the boiler, which, while maintaining what has come to be regarded is the essential feature of the under4pe, inasmuch a.s the firebox, complete with water tubes, . may be lowered and removed from the chassis, allowing of a most thorough cleaning of the inside of the boiler and .tubes, without disturbing any of tiro other components -of the machine. The

'. wall of the firebox itself is,. as will be

the centrally Positioned controls. trations, corrugated, the object of this

construction being to allow of differential expansion and contraction of firebox and outer shell without unduly straining either.

It will be understood that in the inevitable event of either expansion or contraction taking,place the firebox will behave as do the bellows of a concertina. The tubes are curved so as to enter at the top of one corrugation and leave at the bottom of another. They will, therefore, expand and. contraet with the fire_ box. They are not so curved as to be difficult to clean, and; moreover, by their arrangement they facilitate the citculatiort.of the water. It will be noticed that ' this important unit of the chassis is really in two pieces, only having two joints, both plain flanges, one at the top and • one at the bottom of the firebox,' and neither of these joints has to bear the heat Of the fire. There are other less important features of the boiler, as, for example, the arrangement of the ash pan, which may be lowered by the operation of a hand wheel accessible from the driver's seat, and the mechanism for lowering and emptying the grate.

• The engine is located, as is customary, in the middle of the chassis, below the frame. It lies horizontally, the crankshaft being to tho rear. Its interesting feature lies in the valve gear which affords full forward and reverse, as well at intermediate, gear, while using only, oneeccentric for each of the two high pressure cylindeis. The valves themselves are of the piston type. The gear which affords this facility is somewhat difficult to describe. The eccentrics are not mounted on the crankshaft but on a countershaft driven at the same speed at the crankshaft by means of gearwheels. There are two squares forged on this countershaft, which is hollow.

Each eccentric—we hoed only deal with one, as the two are precisely alike— has an oblong hole formed in it which. fits the square on the countershaft, so that it can be slid to and fro on that square. At the ends of the oblong hole slots are formed to accommodate two keys, These keys are of considerable depth, and pass right through from the outside of the shaft to the hollow interior where they engage with a sliding wedge. The last-named is so arranged that., as it, is slid to and fro, it pushes the eccentric, by means of the drop keys, from one to the other of the extreme positions

allowed by the oblong hole. This is devised so that with the eccentric at one extreme position it operates as the forward eccentric of an ordinary reversing gear e with that same eccentric slid to the .411er extreme position it operates as the reverie eccentric. Intermediate positions correspond to intermediate positions in an ordinary link reversing gear with the i particular advantage that n the neutral the engine and gear stand absolutely dead. There is no possibility of slight oscillation such as occurs with the usual link type reversing gear.

• :Many users of steam wagons will appreciate the advantages of a freeengine position, which is not often afforded in the undertype wagon, which does not possess any gear change. In the new Clayton wagon the final drive sprocket rests on a sleeve which is free to revolve upon the crankshaft. The sleeve has an eccentric flange. The crankshaft is prolonged beyond this freely revolving sprocket. and sleeve, and is tapered and keyed to accommodate a driving coupling, which is also eccentric,

• besides being screwed on its outer elmThe new undertype Clayton steamer. eiunference. An outer sleeve is internally View, looking inside theohoiler. threaded to fit this eccentric coupling, and is prolonged so_that when. screwed in to one extreme poeition it envelops the eccentric on the sleeve of the sprocket.

In that position, of course, the whole of the parts revolve solidly with the crankshaft, and means are provided for

Tacking the mechanism there. If the locking plunger be removed and the outer screwed sleeve slacked back until its ex. tension is free of the eccentric flange on the sprocket sleeve, then the engine may revolve freely without transmitting the power.

It is customary on undertype wagons to arrange for the engine to operate effectively as a brake by drawing air from the funnel through the exhaust pipe . and compressing it by the steam pipe back to the regulator valve which 'Is fixed close to the boiler. In the new Clayton this method is improved upon by fitting a small combined draincock and air valve below the engine. Preliminary movement of a lever placed conveniently to the driver's hand opens the draincock and allows air to enter the exhaust pipe. This is at once seen to be an improvement on previous constructions, since the cylinder has not to inhale foul air from the funnel. Further movement of the same lever controls a relief valve, which allows of the pressure in

the inlet pipe being regulated according to the braking needs.

The foregoing are the salient features of the Clayton --undertype, of which perhaps more anon.

The Clayton overtype is, of course, widely known, but in the model which will be seen at Olympia there are several important improvements as compared with former construction. The most outstanding perhaps is the replacement of the low pressure D type slide valve by a piston valve, so that, as now fitted, both high and low pressure valves are of that type. This makes for efficiency both of production and of working. The water pump is now gear-driven from the orank-. shalt instead of,. as previously, from the gearing. It can, therefore, operate while the wagon is standing.

Detailed improvement has taken plaae as regards the construction of the boiler. These make rather for eConomical production, and do not call for considerable attention on the part of the ordinary .,owner driver, except in so far as they affect the working of the wagon. For example, in the course of making. these sundry improvements in boiler and engine opportunity has been taken reduce the whole system to that of unit assembly, and boiler complete with engine, control gear, and so on, are now assembled Cu bloc before being taken to the chassis for ultimate erection.

An incidental improvement which has resulted from the re-arrangement of parts is that the cylinders and engine are lowered, giving a better road view, and this has been carried a step further by arranging the sheet steel guards, etc., so that. the driver is now comfortably protected by means of side doors instead of having to sit, as was hitherto necessary, with one foot inside the shield and the other out.

On the stand will beDemi one of the new undertype

wagons designed for a 6 in load, RS well as an improved model overtype for 5 ton loads and with mechanically end tipping body. The nature of the tipping gear will not he appiiialit to the-observer of the finishea vehicles on the stand. It is entirely novel in design, embodying a steam-driven rotary engine, .very light and simple . in form, driving the usual screw and nut hoisting gear through the medium a gearwheels.

The Halley Six-cylinder 'Models.

HALLEY PRODUCTIONS ha.ye always had a good reputation for sound design and consistent service, and in their latest design Halley's Industrial Motors, Ltd., of Yokel., Glasgow, have aimed at a new standard in commercial vehicle design. Passenger. work hae created a demand for a heavy chassis of greater refinement than hitherto. Users are _demanding a silent and flexible engine and an efficient transmission on a well-sprung frame. With these requirements, the designers of the Halley have niade a bold bid to comply, with theresult that their chaSsis is one of considerable interest.

"u26 • * Very wisely they are concentrating on one type of chassis only, but which can be supplied in two lengths of wheelbase, and is equally suitable for char-a-bancs work or for 3-31 ton loads.

Tlie engine is interesting, being of the six-cylinder type, and of a higher efficiency than s generally sought in a commercial vehicle unit. The cylinders are cast in two sets of three, with detachable heads, and aluminium alloy pistons of the Ricardo slipper type . are used with floating gudgeon pins. The connecting rods are light and very highly finished, and the curved web crankshaft is rnachined all over. Balancing is most carefully carried out, so that a remarkably flexible power unit, capable of a high power output, is obtained. Indeed, it has been necessary to limit the power developed beyond a certain speed by reducing the valve areas. Thus, beyond 1,25Q r.p.m., wire-drawing takes place and renders any governing device unnecessary, The bore and stroke are 31. by 6 ins., and 35 h.p. can be obtained for an indefinite period on the brake at 1,200 revolutions. The valves are on the near side, and are of nickel teel, casehardened, with phosphor-bronze guides. The camshaft is driven by a Morse silent chain, and off-set tappets are used, which rotate when in action, and so obviate pitting. Very accessibly mounted are the water-pump and magneto at either end of a cross-shaft, which is skew driven from the camshaft. Both are driven through laminated spring couplings, and the magneto is provided' with a vernier 'adjustment. Another little point is the use ,of gun-metal spindle vanes and casing for the centrifugal pump, the idea being to avoid corrosion through electrolytic action.

Another good point in the engine is the provision of overhanging lugs on the detachable heads to facilitate removal, which, with a flush head, isnot always easy without damaging the washer.

A ear type oil pump is used, which. supplies crankshaft, 6rinaliaft, and skew gearing by internal oil-ways, the big-ends being supplied by

troughs. There are a dash-. board tell-tale, a crankcase dipper gauge, double filters, and a very conveniently-placed filter.

The fan pro.vides another example of well-thought-out detail, as it is mounted on a. spring-loaded bracket, so that the tension of its V-belt drive is always maintained. The fan is not directly attached to the pulley, but is driven through a simple clutch consisting of a. leather washer . held lip by ,a spring..

• The radiator is mounted on trunnions, and has cast header and b3ttom tanks, connected by round gilled tubes and protected by &oas-rods, channel steel sub-frame. is, used to -carry " the engine, whilst the gearbox is threepoint hung from -two tubular ;

cross-members. The mire , frame is of great strength, consisting of, perfectly straight chatine/s of 5 .ins. by 21 ins. It is built up with the channels outwards, and the cast-steel cross-members, of which there are four webbed, in addition to the two tubular, are not riveted to the side frames, but bolted.

The clutch used is of the single plate type, the steel disc running dry between Ferodo rings, giving a very smooth action and a light clutch shaft, making for easy gear changing. There are three equally-spaced springs, and the clutch spigot is provided with a Skefko bearing. The clutch shaft is equipped with two flexible fabric joints of the Hardy type. The gearbox is very soundly designed, a feature being the caarying out of the oil filter to the side of the chassis. There are four forward speeds, and the gears are all of the straight-tooth type, running on Timken bearings, which are used throughout the transmission. There is an air-rent carried on the gearbox cover, which is of full size, permitting the removal of all gearshafts with the box in position'. The gear qnadrant is carried on the side frame, but frame distortion is provided against by the universal jointing of the cross-shaft. A 'Hardy fabric universal is used at each end of the cardan shaft, and has been found perfectly satisfactory wider such heavy service. Their action is, however assisted by the provision of a ballcentring device which prevents whipping and unnecessary distortion of the fabric. Worm gearing of the David Brown F.J. type is Used, the worm being carried on the cover of the axle casing, which also carries the differential.

The mounting of the foetbrake on the tail and of the .worm shaft is interest ing and sound practice. The fabric universals are thus relieved of braking strains, and a transmission failure does not affect the braking efficiency, whilst the mechanical advantage of the gear redaction is retained.

Semi-elliptic spritis are used front and reap, their length being 3 ft. 3 ins. and 4 ft. 6 its.' and their width 3 ins. and 321 s. rlspectively. The wheels are of the :Cast steel, hollow-spoked type, detachable from their hubs, which are fitted witladanti-rust brass liners and dirtexcluding ga-ticts. Steering is by worm and compla:Aa.v.t.eel, and the steering tiered is earriea n front of the axle.

Al! brake adjuctmente are extremely accessible, and lubrication of all details is rendered as easy as possible. Every effort is made to obtain a consistent standard of quality in this Halley chassis. All materials are testedbefore use, and careful inspecticin en sures accuracy of the finished part. ,Certainly, the Halley chassis and the complete vehicles will constitute -4 leading attraction at the forthcoming Show. The 3 ton Churchill chassis made by Messrs. Durham, Churchill and Co., Ltd., of Grimesthorpe, Sheffield, was described and illustrated by us in our last issue on pages 136 and 137. In our illustration of the chassis the vehicle is Shown mounted

on artillery type wood wheels, but these were only fitted far road tests, and both types of Churchill chassis will be mounted on Lynton steel disc wheels for display at the Show and for delivery to their respective owners.