At Last A iver's Lorry

Page 58

Page 59

Page 60

Page 65

If you've noticed an error in this article please click here to report it so we can fix it.

By John F. Moon,

A.M.I.R,T.E.

66

I

'LL be glad when the governor gets some of these: I know I won't be too happy with my S-type after this." . . The speaker was Len Frisby, a driver with H. E. Dobbs, Ltd., the Enfield haulage contractors who co-operated with inc during the first public road test of one of . the new Bedford TK 7-ton oilers. Frisby's reaction to-driving the TK on the 315-mile journey that he normally does with an S-type 7-tonner was typical of that of the many other drivers who inspected the vehicle during this test.

Although this is undeniably asdriver's vehicle, transport managers and maintenance staff shared the drivers' enthusiasm fof -the design and there is no doubt in my mind that the Bedford TK series will prove to be one of the most popular ranges ever to have been introduced in this country.

The decision to purchase the TK is simplified by knowledge that the majority of the running components are identical with those used in the TC and S models which the TKs supersede. Thus, the road performance, in so far as it affects operational costs, does not differ greatly from that of the earlier vehicles, and operators who already run forward-control Bedfords will therefore know in advance what the new jobs will cost to operate.

Although, .because of wet weather, the fuel consumption and acceleration figuresi obtained during-my test of a TIC 7-tonner were not quite as good as those obtained with the equivalent S-type two years ago, the differences were not of any great significance.

Splendid Value This slight deficiency in performance was—to my mind— more than offset by the vastly improved driving conditions and braking performance, advantages which add only £57 to the basic price of the extra-long-wheelbase TK 7-tonner, compared with the equivalent S-type version. The basic price of the model tested is £1,330 complete with body, the bare chassis being priced at £1,100, or £1,200 when fitted with the standard cab. The improvement between the two models is worth far more than this.

The Bedford TK series was introduced to the British market on September 6, and fully illustrated and described in the September 9 issue of The Commercial Motor. Thus, detailed description of the test chassis is superfluous, as by now the salient features of the range should be well known to the majority of operators.

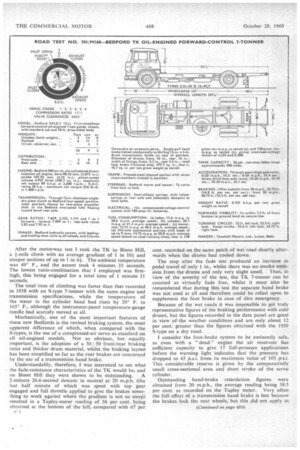

The model submitted for test was a KFLD.1 13-ft. 11-in.wheelbase chassis fitted with the standard TIC cab and Bedford 18-ft. drop-sided timber body. Optional equipment fitted included the Bedford two-speed axle (£95), rearaxle dampers (4,4 18s.), two-man passenger seat (£4), radio (t.17 19s. 7d.), aerial (£2 10s.), two fog lamps (14 each).

heater and demister (£18) and windscreen washer (£1 9s. 6d.).

Thus equipped, the kerb weight of the test TK was 3 tons 14 cwt., which is only slightly more than that of the S-type model with 18-ft. body. Even so, conformation to the manufacturer's recommended gross weight of 10 tons 51 cwt. makes it impossible to carry a true 7-ton payload, that loaded on to the test vehicle totalling only 6 tons 111 cwt. Nevertheless, it was to be shown later that a considerable overload could be handled easily.

For my first test, the 7-tonner was taken out to the usual six-mile fuel-consumption test circuit between Barton and Clophill, an undulating route known to give representative results. It was raining heavily during these tests, and these conditions would tend to be detrimental to the fuel consumption rates obtained. Even so, a figure of 15.6 m.p.g. was achieved at an average speed of 28.6 m.p.h. without the speed exceeding 33 m.p.h. at any time.

On the second day of the test this 'course was retraced unladen, and on this occasion 20.7 m.p.g. was recorded at• 31.3 m.p.h. average speed, the running weight being 3 tons J6 cwt. This means that between 17 and 18 m.p.g. should be obtained by operators who have to run unladen in one direction during the course of normal service.

From the Barton area, the TK was taken on to the MI for full-throttle high-speed consumption tests. The distance of 13 miles out and return was covered in two separate stages to allow the test tank to be topped-up half Way, and, based on the total running time, the average speed for this distance was 48.5 m.p.h. This is a good average for a vehicle with a maximum speed on the level of 54 m.p.h.

The total amount of fuel used indicated an overall consumption rate of 12.25 m.p.g., which I consider good for this type of service, and the vehicle handled remarkably well despite a strong cross wind, there being no noticeable instability and steering vagueness. The large rear-view mirrors and flashing indicators—standard equipment in each case—were of particular value on the motorway.

After the motorway test I took the TK to Bison Hill, a 1-mile climb with an average gradient of I in 101 and steeper sections of up to I in 6i. The ambient temperature was 49° F., and the ascent took 4 minutes 33 seconds. The lowest ratio-combination that 1 employed was firsthigh, this being engaged for a total time of 1 minute 11 seconds.

The total time of climbing was faster than that recorded in 1958 with an S-type 7-tonner with the same engine and transmission specifications, while the temperature of the water in the cylinder head had risen by 20° F. to 165° F., although the instrument-panel temperature-gauge needle had scarcely moved at all.

Mechanically, one of the most important features of these new Bedfords is the revised braking system, the most apparent difference of which, when compared with the S-types, is the use of a compressed-air servo as standard on all oil-engined models. Not so obvious, but equally important, is the adoption of a 50) 50 front/rear braking ratio and thicker drum material, whilst the braking layout has, been simplified so far as the rear brakes are concerned by the use of a transmission hand brake.

Understandably, therefore, I was interested to see what the fade-resistance characteristics of the TK would be, and

on Bison Hill they were shown to be outstanding. A 2-minute 26.6-second descent in neutral at 20 m.p.h. (the last half minute of which was spent with top gear engaged and full throttle applied to give the brakes something to work against where the gradient is not so steep) resulted in a Tapley-meter reading of 56 per cent, being obtained at the bottom of the hill, compared with 67 per

cent. recorded on the same patch of wet road shortly afterwards when the drums had coaled down.

The stop after the fade test produced an increase in pedal travel of only 1 in., whilst there was no smoke emission from the drums and only very slight smell. Thus, in view of the severity of the test, the TK 7-tonner can be counted as virtually fade free, whilst it must also be remembered. that during this test the separate hand brake was not used at all and therefore could be relied upon to supplement the foot brake in case of dire emergency.

Because of the wet roads it was impossible to get truly representative figures of the braking performance with cold drums, but the figures recorded in the data panel are good in view 'of' the weather conditions and are only about 12 per cent. greater than the figures obtained with the 1958 S-type on a dry road.

I consider the foot-brake system to be eminently safe, as even with a " dead " engine the air reservoir has sufficient capacity to give 17 full-pressure applications before the warning light indicates that the pressure has dropped to 45 p.s.i. from its maximum value of 105 p.s.i. This considerable reserve is given by the comparatively small cross-sectional area and short stroke of the servo cylinder.

Outstanding hand-brake retardation figures were obtained from 20 m.p.h., the average reading being 38.5 per cent. as recorded on the Tapley meter. Very often the full effect of a transmission hand brake is lost because the brakes lock the rear wheels, but this did not apply in the case of the test vehicle, despite the wet road. so full effectiveness was available.

Three of these hand-brake stops were made in quick succession, but there was no tailing-off in performance. The only possible source of difficulty that I can visualize as a result of this brake layout would be in the case of a broken propeller or half shaft, either occurrence removing the use of the parking brake. In any "case, more than half the tniaks built throughout the world these days have transmission hand brakes.

Primarily with the object of getting the reactions of a driver who had been used to an S-type 7-tonner with the Bedford oil engine and two-speed axle and standard fourspeed gearbox, I arranged that the TK should he lent to H. E. Dobbs, Ltd., Enfield, for two days so that it could replace one of their normal vehicles on one of their standard long-distance journeys.

• Larger Tyres Fitted

Because Bedfords in the Dobbs' fleet normally carry more than 7 tons they are equipped with 9.00-20-in. (12ply) tyres, so for the purposes of this section of the test this size of equipment was fitted to the test vehicle, the earlier performance tests having been carried out on the standard 8.25-20-in. (12-ply) tyres.

It was as well the larger tyres had been fitted, because the load collected in Enfield for the first delivery consisted of 9 tons of nickel, which had to be taken to Hereford—a distance of 143 miles. From Hereford the TK was driven unladen to Walsall-56 miles—where a 6-ton 3-cwt. load of strip steel was collected for the return run to Enfield.

The total mileage involved was 315, and careful measurement of the fuel used showed a consumption rate of 14.75 m.p.g. The cumulative running time gave an average speed of 30.8 m.p.h., despite the 24-ton overload during the first part of the journey. On the return run from Birmingham the motorway was used at speeds of up to 50 m.p.h., and this helped to push the overall average speed up because on normal roads Frisby drove very considerately.

As can be gathered from the opening remarks in this article, Len Frisby had nothing but praise for the TK, being particularly impressed with the visibility, cab spaciousness, convenience of controls, general handling, suspension and quietness. indeed, his only adverse comment related to the two-speed-axle change and in this respect I agreed with him, the change with the air-pressure control being by no means as .quick or positive as that given by the vacuum mechanism used with vacuum-braked models.

This fault is being attended to, however, and I drove a TK with a modified change mechanism last week, the improvement being pronounced.

Improved Driving Conditions

I find it difficult not to eulogize about the TK from the driver's angle, but am content. to say that it is undoubtedly the biggest single step forward in improving driving conditions that has been made by any British manufacturer in recent years.

in terms of general handling, the TK 7-tonner--even when carrying 9 tons—is remarkably light and safe to drive. The steering is a big improvement on that of the S-types, with good castor and no heaviness, whilst the bikes are infinitely more powerful and, at the same time, lighter to operate. The . suspension, too, is greatly improved, in which respect the 58.5-in.-long front springs help considerably, whilst the gear change, although feeling a little vague initially, is decidedly more convenient to use than that of the S-types.

Unladen, the TK handles almost as well as when carrying a full payload, the steering castor being retained, the brakes never giving any indication of being fierce, and the suspension giving almost as smooth a ride when unladen as when laden. Certainly the combination of long front spring's and telescopic dampers cuts down uncomfortable cab movements to a minimum.

A point with regard to the accessories fitted to the test vehicle is that, in my view, the very effective heater ought really to be standard equipment, as the location of the engine behind the driving position means that none of its heat can penetrate the cab and therefore the driver could become miserably cold in winter. As it is I certainly recommend all purchasers of the TK to specify the heater and consider the i18 to be an essential investment.

When I first saw a TK several months ago I had misgivings about the degree of engine accessibility afforded by the layout, but the maintenance tests I carried out with the vehicle showed that the engine accessibility is far better than that provided by nearly all other forwardcontrol vehicles.

None of the jobs that'! carried out on the power unit presented any difficulty, such as checking the water level (17 seconds), the engine-oil level (30 seconds), the air-filter oil level (45 seconds), removal and replacement of an injector (31 minutes and 3 minutes respectiVely), removal and replacement of the secondary fuel-filter element (1 minute 7 seconds and 1 minute 37 seconds respectively) and venting the fuel system (1 minute 52 seconds).

External Brake Adjusters Non-engine jobs I carried out were to check the gearbox oil level (1 minute 20 seconds), the rear-axle oil level (38 seconds), the battery levels (40 seconds); the brake-fluid level (22 seconds) and adjustment .of the hand brake (28 seconds). The method of adjusting the wheel brakes differs from that employed on the S-types in that external adjusters are fitted, but the tool kit does not include a small enough spanner to fit these comfortably, with the result that I took 6+ minutes to adjtist the rear brakes and the same time for the front.

Spare wheel removal was light and easy, the wheel being carried by a winch mechanism, and I removed the wheel in 31 minutes and restowed it in the same time. Only the wheelbrace is needed for both operations. .

For a mass-production vehicle the standard tool kit is fairly comprehensive, and all the items are neatly stowed in the engine compartment, although, because this cannot be locked, theft is an ever-present possibility. In addition to a hydraulic jack and handle, timing handle and wheelbrace, a tool roll containing two open-ended spanners, one large adjustable spanner, a pair of pliers and a screwdriver is provided.