HANDLING THE GIANT TYRE IN THE GARAGE

Page 86

Page 87

If you've noticed an error in this article please click here to report it so we can fix it.

There is on the Market Some Ingenious and Highly Efficient Equipment for Dealing with Large Pneumatics, and This Article Gives a Good Idea of

What is Offered

IN a previous article appearing in our issue dated August 19th we described some of the equipment by which the removal of :a wheel from a heavy vehicle is facilitated, also mechanical means for detaching a giant tyre from a wheel, as well as its replacement on

that wheel and the return of the wheel to its place on the axle of the vehicle.

For transferring the wheel from vehicle to tyre-removing appliance what was called a truck-wheel attachment was recommended to be used in conjunction with a heavy jack. An alternative appliance not then described is the Truck Wheel Dolly, a piece of Manley equipment, this being a special class of trolley with adjustable brackets for supporting the wheel. Really this dolly combines in the one self-contained item of equipment that jack and truck wheel attachment to which reference was made in the previous article.

Two types of giant-tyre remover were described, namely, the Weaver and the }IF Robot. The methods of using these machines and the relative advantages of each had reference in the article.

We now come to the next stage in the proceeding, which is the preparation of the giant tyre for inspection and repair. This at first sight might seem a trivial matter, one not involving the necessity of any prolonged consideration and hardly needing elaborate equipment. A little experience, however, of the difficulty of manipulating the covers of modern giant pneumatic tyres by hand will serve to convince the most sceptical persons that mechanical assistance of some sort is not merely desirable, but most essential.

Tyre-handling Equipment.

There is, as a matter of fact, ample equipment of this type on the market. Some of it is manually operated and some power controlled, the source of power being invariably compressed air, supplies of which are presumed to be available where ever giant pneumatic tyres are in use.

The manually operated equipment usually takes The form of a conk

bination of levers having a• toggle action designed so that, in the closed position, the ends of the levers engage with the beads of the tyre and, when open, those beads are thrown wide, thus exposing the inside of the cover for inspection and, where necessary, for repair. The levers hold the beads apart while that is effected.

A typical example of such equipment is produced by the Dunlop Rubber Co., Ltd., Fort Dunlop, Erdington, Birmingham. The price is 15s., but a pair is really necessary in order sufficiently to open the cover and to hold it open. Another lever of a similar type is the Quikko (J. W. Pickavant and Co., Ltd., Quikko 'Works, Granville Street, Birmingham), and another the BF (Harvey, Frost and Co., Ltd., 148, Great Portland Street, London, W.1).

Power Tyre Spreaders.

It has to be admitted, however, that with the best of these manual devices considerable exertion is required in order to open the tyre and, generally, if the amount of work to be done justifies the expenditure, power-operated gear is to be recora

mended. There are several varietieS of power tyre spreaders on the market.

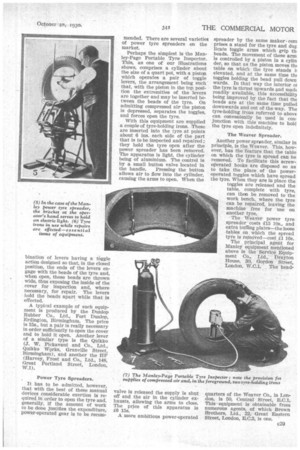

Perhaps the simplest is the Manley-Page Portable Tyre Inspector. Th58, as one of our illustrations shows, comprises a cylinder about the size of a quart pot, with a piston which operates a pair of toggle levers, the arrangement being such that, with the piston in the top position the extremities of the levers are together and may be inserted between the beads of the tyre. On admitting compressed air the piston is depressed, separates the toggles, and forces open the tyre.

With this equipment are supplied a couple of tyre-holding irons. These are inserted into the tyre at ppints about 6 ins, each side of the part that is to be inspected and repaired ;• they hold the tyre open after the power spreader has been removed. The apparatus is light, the cylinder being of aluminium. The control is by a small button valve located in

the handle. Pressing the button allows air to flow into the cylinder, causing the arms to open. When the valve is released the supply is shut off and the air in the cylinder exhausts, allowing the arms to close. The price of this apparatus is 16 15s.

A more ambitious power-operated

spreader by the same maker com prises a stand for the tyre and dup licate toggle arms which grip th, beads. The movement of these arm: is controlled by a piston in a cylin der, so that as the piston moves tin table on which the tyre stands b elevated, and at the same time tin toggles holding the bead pull down wards. In that way the interior ol the tyre is thrust upwards and mad( readily available, this accessibility being improved by the fact that thE beads are at the same time pulled downwards and out ofthe way. The tyre-holding irons referred to above can conveniently be used in conjunction with this machine to hold the tyre open indefinitely.

The Weaver Spreader.

Another power spreader, similar in principle, is the Weaver. This, however, has the feature that the table on which the tyre is spread can be removed. To facilitate this screwoperated hooks are disposed so as to take the place of the poweroperated toggles which have spread the tyre. When they are in place the toggles are released and the table, complete with tyre, can then be removed to the work bench, where the tyre can be repaired, leaving the machine free for use on another tyre.

The Weaver power tyre spreader costs i15 10s., and extra buffing plates—the loose tables on which the spread tyre is removed—cost £.1 16s.

The principal agent for Manley equipment mentioned above is the Service Equipment Co., Ltd.; Drayton House, 30, Gordon Street, London, W.C.1. The head quarters of the Weaver Co., in London, is 50, Central Street, E.C.1. This equipment is obtainable from numerous agents, of which Brown Brothers, Ltd., 22, Great Eastern Street, London, E.C.3, is one.