FORD VAN POINTERS.

Page 28

Page 29

If you've noticed an error in this article please click here to report it so we can fix it.

By R. T. Nicholson (Author of "The Book of the Ford ").

" KNOW what's the matter with me," said the parrot in the story, "I talk too much!"

. And judging from letters which I have recently received, the Ford might very well say, "I know whaes the matter with me, I chatter too much ! "

450.—On Chattering.

What is chattering! My dictionary defines it thus : (Of birds) utter quick series of short notes ; (of persons) talk quickly, incessantly, foolishly, or inopportunely ; (of teeth) rattle together (also of illadjusted parts of machine).

It is in the last Sense of the word that it is used in relation to the Ford. " Shivering" and " shuddering," as well as " stuttering," are also terms occasionally used.

Anybody who has suffered from this trouble knows too well what it meana. When one of the transmission pedals, or the brake pedal, is pushed down— particularly in starting or stopping, and whether in forward or reverse movement—a kind of harsh tremor arises, which seems to set the engine and the whole chassis in nerve-racking vibration. The ailment may affect all three pedals, or it may wholly or specially arise from one.

The CauseThere are all sorts of theories as to the cause of chattering. There are those who hold that it is altogether a question of the. material used for lining the transmission and brake bands ; others believe that it is due to improper lubrication of the linings ; others again say that it depends on the condition of the linings; and various deeper-seated causes are held responsible.

There being different theories as to the cause of chattering, it is natural that different cures should be prescribed. Where doctors differ in diagnoses, remedies will certainly vary.

The Ford Co. themselves seem to take the view that a band lining of a soft, yielding material is the best means of preventing chattering. So, the standard Ford lining is made of a material in which cotton figures largely. And I am boundao say that it is only very exceptionally that there is any chattering on a new Ford with new linings to the bands.

But I am bound also to say that after considerable use, particularly after unfair use, chattering can quite well arise from those cotton fabric linings. (I will say presently what I mean by "unfair use.") B10 Moreover, being soft, they have not too long a life. Further, they rather readily burn (from overmuch friction) and glaze ; and once they have gotburnt and glazed they lose their soft, yielding character, and then chattering starts. Cotton linings are rather like those soft, yielding women who are so sweet and submissive before marriage, and who too often prove otherwise later on, and nag, nag, nag, incessantly. You know what I mean I—or, rather, I hope you do not !

To overcome the difficulties attaching to soft linings which are soft throughout their whole length, some manufacturers have combined a soft material with a harder one—something on the same principle as the makers of steel-studded tyres. Insets of various kinds have been tried, notably cork discs. There is no doubt that these mixed material bands do give very " sweet" grips, but the trouble is that the soft parts tend to wear out first, so that the main grip on the drums is taken by the harder material, and then comes the liability to chattering.

Another form of remedy lies in attachment of a grease cup filled with a special lubricant. It is much advertised in America, though I do not think it has yet reached this country.

Recognizing the troubles attaching to the use of soft material for the band linings, some manufacturers have produced linings of a hard material— often with an asbestos base—which resist wear and burning. These have the' great advantage of being long-lived, but, alas they do not overcome chattering trouble.

—And Its Prevention.

When the soft linings are' fitted, the best way to prevent chattering is to prevent the bands getting glazed or burnt—to prevent their contact surfaces from becoming hard and inelastic. But how ? Simply by never using any one pedal for too long together. If you keep any one lining in hard frictional contact with its drum for a long time on end, you are bound to burn it, and even if you do not burn it you will glaze it if the oil gets dried out by the heat.

This caution applies especially to the foot-brake lining. That is, of course, a friction brake, the band of which bears upon the brake drum, without, however, holding it—unless very roaghly anplied. (If you apply it too rourialy, you may stop the engine, and then the transmission brake ceases to be a brake proper.) The foot-brake band is intended to allow the corresponding drum to turn inside it.

The slow-speed band, on the other hand, is not meant to allow the slow-speed drum to turn inside it ; the band should in this case grip and hold the 'drum. At first contact, however, 'there is always a certain amount of slip between band and drum, though there is rarely enough to produce enough frictional heat to glaze or burn the lining.

So, too, with the reverse band and drum. When the reverse is used only for reversing, the action is a gripping and holding action; there is no slip, except, perhaps, just at starting. When, however, the reverse is used as a brake,. there is slip, because, in that ease, the band does not hold the drum. In that case, therefore, enough frictional heat may be produced to glaze and burn the lining. When, therefore, you use the foot brake or the reverse as brake do not use either of them for any length' of time on end—say, not more than 10 sees. If you do you will more than likely scorch the linings or harden their contact surfaces. If you.free them after a short use they will have time to cool ; moreover, they will pick up oil from the engine supply, which will not only cool them, but will reduce friction (and heat) at next contact.

My Own Theory of the Cause of Chattering.

It is not only the Ford that chatters. All cars (or other motors) on which band brakes are used are liable to suffer from the trouble. The reason why it is specially noticeable in the ease of the Ford is that the Fort]. has three bands and three drums, se that the liability becomes greater.

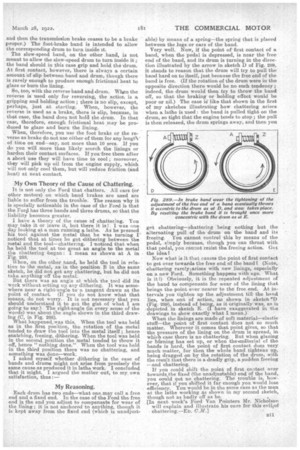

have a theory of the cause of chattering. You may take it or leave it, but there it is! I was one day looking at a man running a lathe. As he pressed his tool against the metal that he was turning I noticed that at times he got dithering between the. metal and the tool--chattering.. I noticed that when he held the tool at too great an angle to the metal the chattering ibegan : mean as shown at A in Fig. 283.

When, on the other. hand, he held the tool in relation to the metal, as: in the position B in the same sketch, he did not get any .chattering, but he did not take anything off the metal. But there was an angle at which the tool did its work without setting up any dithering. It was somewhere near a right-angle to a tangent drawn at the point of contact. (If you do not know what that means' do not worry. It is not necessary that you should understand it to get the gist of what I aiim going to say.) The right-angle (in every sense of the words) was about the angle shown in the third drawing (C, in Fig. 288). What happenedeva.s this. When the teal was held as in the first position, the' rotation of the metal tended to draw the tool into the metal itself ; hence snatching, freeing, dithering. When the tool was held in the second position the metal tended to throw it off, hence" nothing done." When the tool was held in the third position there was no chattering, and something was done—work. I asked myself whether dithering in the case of bands and drums might not arise from precisely the same cause as produced it in lathe Work. I concluded that it Might. I argued the matter out, to my. own satisfaction, thus :— My Reasoning.

Each drum has two ends—what one_may call a free end and a fixed end. In the case of the Ford the free end is, the end yen adjust to compensate for wear of the lining ; it is not anchored to anything, though it is kept away from the fixed end (which is unadjust able) by means of a spring—the spring that is placed between the lugs or ears of the band.

Very well. Now, if the point of first centact of a band, when the pedal is depressed, is near the free end of the band, and its drum is turning in the direction illustrated by the arrow in sketch D of Fig. 289, it stands to reason that the drum will try to pull the band hard on to itself, just because the free end of the band is free. (If the rotation of the drum were in the opposite direction there would be no such tendency; indeed, the drum -would then try to throw the band off, so that the braking or holding effect would be poor or nil.) The case is' like that shown in the first of any sketches illustrating how chattering .arises when a lathe is used : the band is pulled tight on the drum, so tight that the engine tends to stop ; the pull is then released, the drum springs away, and then you get chattering—chattering being nothing but the alternating pull_ of the drum on the band and its freeing. You cannot control this by means of the pedal, simply because, though you'can thrust with that pedal, you cannot resist the freeing action. Got the ideal Now what is it that causes the point of first contact to get over towards the free end of the band? (Note, Chattering rarely-,arises with new linings, especially on a neW Ford. Something happens with age. What is it?) Obviously, it is the repeated adjustment of the hand to compensate for wear of the lining that brings the point ever nearer to the free end. At intervals' you tighten up the adjustment till the bend when out of action, ;as shown in 'sketch t'D (Fig. 289), instead of being., as it originally was, as is depicted in sketch E. (I have exaggerated in the drawings to show exactly what I mean.)' When the linings are made of soft material—elastic stuff—the point of first Contact does not so much matter. Wherever it comes that point gives, so that the pressure of the lining on the drum is spread, in which case there is no chattering. But when glazing or Miming has set up, or when thetanffterial of the bands is hard, the point of first contact does very much matter, for then the whole band tightens up, being dragged on by the rotation of the drum, with the result that there is a deadly grip, asudden freeing —and chattering. If you could shift the point of first contact over towards,the fixed (the unadjustable) end Of the band, you could get no chattering. The trouble is, however, that if you. shifted it far enough you would lose efficiency. You would be in the same case as the man at the lathe working is shown in my second sketch, though not as badly off as he. [In next week's Ford Ilan 'ointers Mr. Nicholson will explain and illustrate his cure for this evileof • chatternige—ED. CAL]