Road Rolling Without Ridging

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

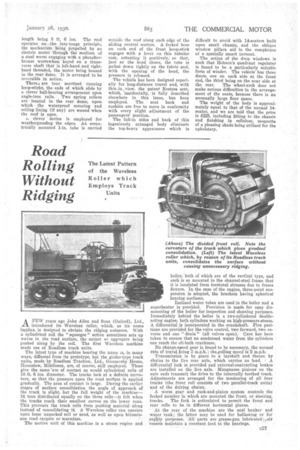

The Latest Pattern of the Waveless Roller which Employs Track Units AFEW years ago John Allen and Sons (Oxford), Ltd., introduced its Waveless roller, which, as its name implies, is designed to obviate the ridging nuisance. With a cylindrical roll the " squeegee " action sometimes gets up waves in the road surface, the carpet or aggregate being pushed along by the roll. The first Waveless machine made use of Roadless track units.

The latest type of machine bearing the name is, in many ways, different from its prototype, but the girder-type track units, made by Roadless Traction, Ltd., Gunnersby House, Hounslow, Middlesex, are, of course, still employed. These give the same 'arcof contact as would cylindrical rolls -of 16 ft 6 ins. diameter. The tracks lock at a definite curvature, so that the pressure upon the road surface is applied gradually. The area of contact is large. During the earlier stages of surface consolidation the angle of approach of the track is slight, but the full weight of the machine16 tons distributed equally on the three rolls—is felt when the tracks reach their smallest curves on the lower runs. This prevents the track rolls from pushing material along instead of consolidating it A Waveless roller can operate upon loose unpacked soil or sand, as well as upon bittimin ous road carpets or macadam.

The motive unit of this machine is a steam engine and

boiler, both of which are of the vertical type, and each is so mounted in the channel-steel frame that it is insulated from torsional stresses due to frame flexure. In the case of the engine, three-point suspension is adopted, the brackets having spherical bearing surfaces.

Inclined water tubes are used in the boiler and a superheater is provided. Provision is made for easy dismounting of the boiler for inspection and cleaning purposes. Immediately behind the boiler is a two-cylindered doubleacting engine, both cylinders working on high-pressure steam. A differential is incorporated in the crankshaft Five positions are provided for the valve control, two forward, two ,reverse and one " drain " (all valves open). Care has been taken to ensure that no condensed water from the cylinders can reach the oil-bath crankcase.

No change-speed gear is found to be necessary, the normal rate of travel, being 3 m.p.h.; theoolling speecr is 2 m.p.h. Transmission is by gears to a layshaft and thence by chains to the live rear axle, which carries no load. A differential lock is provided and external-contracting brakes are installed on the live axle. • Manganese pillions on the axle ends transmit the drive to the internally toothed track. Adjustments are arranged for the tensioning of all: four tracks (the front roll consists of two parallel-track units) and of the driving chains. . A Worm gear and rack-and-pinion system controls the forked member in which are mounted the front, or steering, tracks. The fork is articulated to permit the front and ' rear rolls to be in different horizontal planes.

At the rear d' the machine are the coal bunker and water tank ; the latter may be used for ballasting. or for 'sup% purpoSes. All parts are grease-gun lubricated ; ,air

'vessels maintain a constant feed to the bearings. "