Retank at hall the cost

Page 97

Page 98

If you've noticed an error in this article please click here to report it so we can fix it.

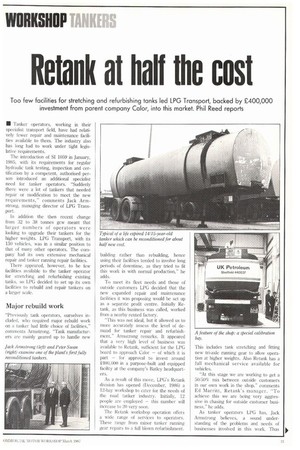

Too few facilities for stretching and refurbishing tanks led LPG Transport, backed by £400,000 investment from parent company Color, into this market. Phil Reed reports

• Tanker operators, working in their specialist transport field, have had relatively fewer repair and maintenance facilities available to them, The industry also has long had to work under tight legislative requirements.

The introduction of SI 1059 in January, 1985. with its requirements for regular hydraulic tank testing, inspection and certification by a competent, authorised person introduced an additional specialist need for tanker operators. "Suddenly there were a lot of tankers that needed repair or modification to meet the new requirements," comments Jack Armstrong. managing director of LPG Transport.

In addition the then recent change from 32 to 38 tonnes gcw meant that larger numbers of operators were looking to upgrade their tankers for the higher weights. LPG Transport, with its 150 vehicles, was in a similar position to that of many other operators. The company had its own extensive mechanical repair and tanker running repair facilities.

There appeared, however, to be few facilities available to the tanker operator for stretching and refurbishing existing tanks, so LPG decided to set up its own facilities to rebuild and repair tankers on a larger scale.

Major rebuild work

"Previously tank operators, ourselves included, who required major rebuild work on a tanker had little choice of facilities," comments Armstrong. "Tank manufacturers are mainly geared up to handle new building rather than rebuilding, hence using their facilities tended to involve long periods of downtime, as they tried to fit this work in with normal production," he adds.

To meet its fleet needs and those of outside customers LPG decided that the new expanded repair and maintenance facilities it was proposing would be set up as a separate profit centre. Initially Retank, as this business was called, worked from a nearby rented factory.

"This was not ideal, but it allowed us to more accurately assess the level of demand for tanker repair and refurbishment," Armstrong remarks. It appeared that a very high level of business was available to Retank, sufficient for the LPG board to approach Calor — of which it is part — for approval to invest around i:400,000 in a purpose-built and equipped facility at the company's Batley headquarters.

As a result of this move, LPG's Retank division has opened (December, 1986) a 12-bay workshop to cater for the needs of the road tanker industry. Initially, 12 people are employed — this number will increase to 20 very soon.

The Retank workshop operation offers a wide range of services to operators. These range from minor tanker running gear repairs to a full blown refurbishment.

This includes tank stretching and fitting new tri-axle running gear to allow operation at higher weights. Also Retank has a full mechanical service available for vehicles.

"At this stage we are working to get a 50/50%. mix between outside customers in our own work in the shop," comments Ed Marritt, Retank's manager. "To achieve this we are being very aggressive in chasing for outside customer business," he adds.

As tanker operators LPG has, Jack Annstrong believes, a sound understanding of the problems and needs of businesses involved in this work. Thus Retank's service has been designed to provide a completely specialised cover to minimise cost and downtime.

Take, for example, the problems of leaking tanks which generally occur at the most inconvenient times. Ed Marritt reckons that Retank is able to deal with any tanks brought in with leaks immediately. If the problem requires that the tank is to be unloaded then the site's facilities include separate storage tanks into which the load can be transhipped.

Immediate service is a requirement for many types of tanker repair and Retank is geared up to provide this. As part of the Retank service is a complete tank cleaning facility and the ability to provide gasfree certificates.

For long-term work such as refurbishing, Retank has the facility to lend operators a free replacement tank to minimise the effects of downtime. Refurbishment work is an area which Retank expects to provide a large part of its business.

"With the facilities we have here we can handle every aspect of tank mainten ance, repair and refurbishment," reckons

Ed Marritt. The all-new Retank shop is equipped with a 7.5-tonne capacity

overhead crane, calibration bay, MIG and TIG welding facilities, sheet rolling, folding and shearing equipment.

Refurbishment demand is obviously high; already around a dozen jobs are waiting for this kind of attention. Retank starts this operation first by thoroughly cleaning and de-gassing the tank.

Up-grading the shell

Then the cladding, sheeting and insulating material is removed and the tank shell is completely stripped. This allows the condition of the shell to be assessed. An ultra-sonic survey is carried out to discover shell thickness throughout the tank structure. At this stage Retank can then report to the operator on the tank shell condition.

Work then commences on up-grading the shell. Retank is able to weld steel, aluminium or stainless steel. Straightening and strengthening work is carried out as required. If the tank is to be enlarged Retank rolls and fits new sections to suit. From the re-build upwards Retank tries to use as much stainless steel as possible including tank bearers and lagging supports. Insulation is fitted to customer specification and the exterior re-sheeted in fibreglass, stainless steel or alloy as required.

Before re-sheeting, all chassis modifications are made for the new running gear. Most of Retank's refurbishment work to date has included uprating for 3tonne operation whether by fitting new tri-axle running gear or widespread tandem-axle bogies. New side-guards are also fitted and the man-lids, valves and other items are renewed with equipment specified by the operator.

In general terms Retank reckons that a fully refurbished tanker will cost £16,000 to i:17, 000 dependent upon specification. This, according to Ed Manitt and Peter Swan, who is in overall charge of the Retank operation, is around 50% cheaper than the equivalent new tanker. And for a typical 14-year-old tanker unit both Peter Swan and Ed Marna believe that with a Retank refurbishment operators can expect a further 12 years' operational life.

Retank can weld to ADR ASME 6G approved standards. Also the company is able to carry out vehicle re-wiring to meet the tough ADR standards.

Other work carried out by Retank includes SI 1059 testing and calibration for which the dedicated specialist equipped calibration bay is used. Also carried out at Batley are major tank repairs and modifications such as fitting discharge equip rnent, hose reel/meter conversions and vapour collection systems. Tank transfer and remounting is also carried out on rigid vehicles.

Another service Retank offers is full petroleum regulation conversions for tractive units. "We believe that Retank offers a genuinely complete service in this respect," comments Ed Marritt. The company will collect a stock tractive unit for an operator, carry out petroleum regulation specified wiring, exhaust and fire screening work and deliver back to the operator within four to five working days.

Retank will also supply and fit fifthwheel and mud-wings as required. Although the company does not have its own facility for painting, this work can be arranged through a local sub-contractor. Retank is investigating the volume of paint business with a view to installing its own facility. This work would neatly complement its existing facilities which also include a full shot-blasting capability.

Other Retank services include the supply and fitment of tanker discharge, power take-off, pumps and compressors. Among the sign holdings held by the company are those for Volvo Hydraulics and Hammond Engineering equiment.

"In fact," says Ed Marritt, "we are offering a full range of services to tank operators from front to rear bumper."