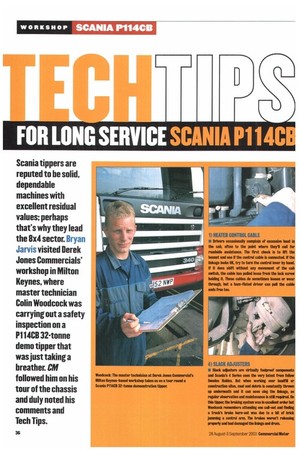

1) HEATFP CONTROL CABLE

Page 36

Page 37

Page 38

If you've noticed an error in this article please click here to report it so we can fix it.

• Drivers occasionally complain of excessive heat in the cab, often to the point where they'll call for roadside assistance. The first check is to lift the bonnet and see if the control cable is connected. If the linkage looks OK, try to turn the control lever by hand. If it does shift without any movement of the cab switch, the cable has pulled loose from the lock screw holding It. These cables do sometimes loosen or wear through, but a barn-fisted driver can pull the cable ends free too.

2) AIR CLEANER

• Take care when working over rough pasture not to ground the front end. Some drivers drive too quickly across landfill sites, which can lead to the rubber sediment drain tube being wrenched from the base of the air fitter. Once this happens, dirt and mud will be sucked up into the fitter housing and then ifs only a matter of time before the muck begins to block the filter element and the power starts to fall away. Eventually the truck will grind to a haft at the roadside. Drivers on site work, as well as mechanics, should get used to casting an eye over these very critical fittings.

3) PROPSHAFTS

• Unlike the previous 3 Series, the newer range has sealed-for-life universal joints on the main propshaft, but not on the rear intermediate shaft that links the drive axles. This has to work through such acute angles under extreme forces that it has to be hand-lubricated regularly. Importantly, the securing bolts need torqueing up at every service; 17011m for the main prop and 1101lin on the short rear shaft. The drawback with maintenance-free universal joints is if one of the spider bearings develops 'lift', they both have to be replaced. 4) SLACK ADJUSTERS

• Slack adjusters are virtually foolproof components and Scania's 4 Series uses the very latest from fellow Swedes KaIdes. But when working over landfill or construction sites, mud and debris is constantly thrown up underneath and it can soon clog the linkage, so regular observation and maintenance is stil required. On this tipper, the braking system was in excellent order but Woodcock remembers attending one call-out and finding a truck's brake burn-out was due to a bit of brick jamming a control arm. Ilw brakes weren't releasing properly and had damaged the linings and drum.

5) INNER WINGS

• Another change for the better is the fitting of metal inner wing guards between the steering axles. The old plastic shields an previous models were far too flexible and failed to protect components located behind thorn. On the nearside, air pipes, handbrake and trailer control valves were often damaged by flying rubble and left the driver in need of recovery.

6) HEADLIGHT WIRING

• Woodcock always spares a moment to check the headlight wiring harness to see if the corrugated protective sleeving is doing its job. Early 4 Series don't have this and quite often the vibrations can cause the wires to fray against the securing bracket. lithe examiner doesn't spot the impending problem, it won't be long before fuses start blowing. 7) BRAKE LINING INSPECT/11N rfliqr:Pc'

• Brake lining inspection covers should always be replaced properly, otherwise muck will farce its way in and soon throw the ABS sensing out of kilter. Here, water or dirt is lying between the sensor and exciter ring on axles two and four, left side, and this has shown up as an ABS faun on the Sonia diagnostic system. Don't waste time with any short cut—strip the wheel station down and clean it off thoroughly.

8) SCANsA nIgrIMc!TIrF:

• Using the diagnostics laptop computer is second nature to Scania technicians, and checking this vehicle's main ECU for faults reveals the ABS problems mentioned previously, plus an irregular beat and slightly excessive fuel consumption. Fault code 57 can be traced right back to the unit injector springs and with this clever but expensive tool, Woodcock will readjust their spring height settings. "It's not a common problem, but it is just a part of the bedding-in process," he says. The diagnostic check is included with every service on Scania 4 Series and on some of the later 3 Series too.

9) NO COOLANT FILTER

• Simla has at last acquiesced regarding the cooling system's filtration system and dispensed with both it and the cut-off tap attogether. They leaked often and broke both the hearts and nails of technicians sent out at night to repair them on the hard shoulder. Scania has blanked off the fitting flange and finally reverted to using conventional anti-freeze mixtures.

10) CAB SUSPENSION

• With the vehicle on the level, check that there's adequate clearance between cab and bump stop (1015mm at least) and listen for any air leaks too. The earlier cab suspension valve was prone to leaking and has been replaced with one that is much MOM reliable. The revised valve assembly can also be retrofitted to 3 Series models.

11) INTERCOOLER HOSE

• A check of the intercooler ducting shows dark staining on the nearside hose. This is on the 'het' inlet side and oil has begun seeping around the top clip. If ignored, the seepage will develop into gradual power loss—and one day it will expire attogether, leaving the driver stranded. The vehicle's original hose will be replaced with the latest design, which has been reinforced at each end with an inner steel ring. This extra support is enough to prevent them from blowing through.

12) FAN COWLING BRACKET

• A central mounting and a brace of sturdy-looking side brackets secure the cooling fan cowling on the 4 Series engine. But the side brackets are made from cast aluminium and are prone to snapping; more often than not, it's the right-hand side support that breaks first. Sometimes the crack is just hairline—but it's up to the examiner to spot them early on, otherwise if they start flapping during a long journey, other damage could occur.