DIMPLE MECHANICS

Page 77

If you've noticed an error in this article please click here to report it so we can fix it.

CLUTCHES -2

N,4,74,„„ptor

MANY of the lighter hides the coil springs used force the clutch pressure ite tight against the centre tte, as described in the last icle, have been replaced by ingle diaphragm spring.

When unloaded this spring of conical form; when the itch is assembled this cone is ttened out into a simple disc d exerts considerable thrust the pressure plate. Withmai levers are not needed th this type of clutch as the itch release bearing bears .ectly on to a ring in the ntre of the diaphragm -ing.

When space is limited or iere very large torques have be transmitted multiplate itches may be employed. )tor cycles, in particular, use is type of clutch. These itches may be "dry" as .eady described or "wet" Jere the clutch runs in oil. In s case one set of plates may made of steel and the other )nze, or the plates may have rk inserts. Some heavy mmerciat vehicles have dry in plate clutches to deal th the high torque which 5 to be transmitted.

When there is a very large itre plate the clutch may ninue to spin long after the itch pedal has been pressed, Lking gear changing diffiIt. In the larger clutches me form of clutch brake is ted. This is brought into eration just before the tch pedal is fully depressed; ad or disc lined with friction terial is brought into con,t with a disc on the centre te or gearbox input shaft. "Autch faults fall into three .in categories: the clutch ping, failing to free when ; pedal is pressed, and clutch Icier. With the former fault L clutch fails to engage fully; engine revs but the vehicle y moves quite slowly. A iracteristic acid smell and netimes smoke comes from clutch and eventually the iicle refuses to move at all. Clutch slip may be caused by the following defects: (a) Clutch linings excessively worn. This fault can only be rectified by dismantling the clutch and fitting a new centre plate.

(2) No free play at pedal. As the friction linings wear, the pressure plate moves closer to the flywheel, reducing the clearance of the release bearing until there is no free movement of the clutch pedal. This is a common fault, particularly with mechanically operated clutches, and it produces the same effect as if the driver habitually drives with his foot on the clutch pedal, partially, if ever so slightly, disengaging the clutch.

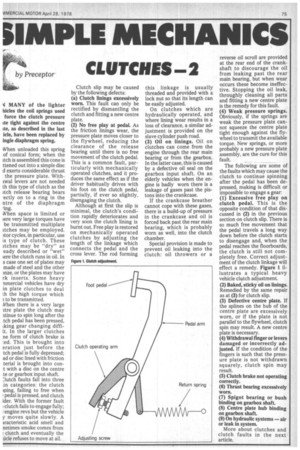

Although at first the slip is minimal, the clutch's condition rapidly deteriorates and very soon the clutch lining is burnt out. Free play is restored on mechanically operated clutches by adjusting the length of the linkage which connects the pedal and the cross lever. The rod forming this linkage is usually threaded and provided with a lock nut so that its length can be easily adjusted.

On clutches which are hydraulically operated, and where lining wear results in a loss of clearance, a similar adjustment is provided on the slave cylinder push road. (3) Oil on linings. Oil on clutches can come from the engine through the rear main bearing or from the gearbox. In the latter case, this is caused by a defective oil seal on the gearbox input shaft. On an elderly vehicles when the engine is badly worn there is a leakage of gases past the pistons into the crankcase.

If the crankcase breather cannot cope with these gases, there is a build-up of pressure in the crankcase and oil is forced back past the rear main bearing, which is probably worn as well, into the clutch chamber.

Special provision is made to prevent oil leaking into the clutch: oil throwers or a reverse oil scroll are provided at the rear end of the crankshaft .to discourage the oil from leaking past the rear main bearing, but when wear occurs these become ineffective. Stopping the oil leak, throughly cleaning all parts and fitting a new centre plate is the remedy for this fault.

(4) Weak pressure springs. Obviously, if the springs are weak the pressure plate cannot squeeze the centre plate tight enough against the flywheel to transmit the available torque. New springs, or more probably a new pressure plate assembly, are the cure for this fault.

The following are some of the faults which may cause the clutch to continue spinning after the pedal has been depressed, making is difficult or impossible to engage a gear: (1) Excessive free play on clutch pedal. This is the opposite condition of that discussed in (2) in the previous section on clutch slip. There is so much free movement that the pedal travels a long way down before the clutch starts to disengage and, when the pedal reaches the floorboards, the clutch is still not completely free. Correct adjustment of the clutch linkage will effect a remedy. Figure 1 illustrates a typical heavy vehicle clutch adjustment.

(2) Baked, sticky oil on linings. Remedied by the same repair as at (3) for clutch slip.

(3) Defective centre plate. If the splines on the hub of the centre plate are excessively worn, or if the plate is not parallel to the flywheel, clutch spin may result. A new centre plate is necessary.

(4) Withdrawal finger or levers damaged or incorrectly adjusted. If the condition of the fingers is such that the pressure plate is not withdrawn squarely, clutch spin may result.

(5) Clutch brake not operating correctly.

(6) Thrust bearing excessively worn.

(7) Spigot bearing or bush binding on gearbox shaft.

(8) Centre plate hub binding on gearbox shaft.

(9)On hydraulic systems — air or leak in system.

More about clutches and clutch faults in the next article.