Golden rules for tipper workshops

Page 42

Page 43

Page 44

If you've noticed an error in this article please click here to report it so we can fix it.

Start off clean and keep it tight— it's an investment.

lain Sherriff describes how to design and run a workshop

DESIGNING a workshop for a tipping fleet is little different from designing one for a general haulage fleet. But as with most things in life, it is the little things that make or break a project: Before starting to build, follow these golden rules: • Engage an architect. He will see the project through its local government planning stages, ensure that the type of structure that is erected meets the requirement and he will act as clerk of works.

• Don't leave it all to the architect. Without interfering with his brief make sure he in cludes everything that is required to maintain a tipper fleet.

• And don't limit the scope to the conversion of an old building, it frequently costs less to knock it down and start again.

• Provided the land is there, allow for double or treble the number of vehicles in today's fleet. Remember, the area costs more than the structure in most locations.

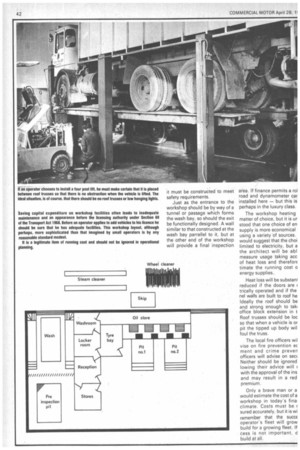

The workshop starts outside in the yard. A clean workman is a good workman and for this reason mechanics should be presented wlth clean vehicles to work on

The first requirement there

fore is a wheel cleaner sunk into the yard in line with the entrance to the workshop. Alongside have a refuse skip where drivers can drop their cab debris. The old ropes, bottles, boots and papers a driver collects may have a sentimental value for him, to the mechanic they are obstructions.

Steam clean

Between the wheel cleaner and the entrance is the next step in cleanliness — the steam cleaner, ramp and drain. Whether or not steam cleaner is fixed or portable and operated by gas, electricity or paraffin i! matter of choice but the rar should provide an effective b. rier between the outside wo and the workshop.

The next step is inside t building and on to the vehii wash. This should run on t same lines as the steam cleani bay with the same drain servi both.

The washing bay should ha 4 ft high platforms each si and running its full length. TI ensures that the driver wash inside as well as outside I body. The bay itself should constructed in the form of tunnel to protect the worksh area.

Ahead of the wash it is wi to locate a pre-inspection arE Adjacent to it should be sited t records office and stor together with the wash roc and locker room and toilets; would be limited to the sar mains services.

The main area having be separated from the wash bay a suitably clad wall is no It subject to detail than the ap€ dages. However, over sophit cation should be avoided.

Head room

The most common fault premises converted for tip!: vehicle maintenance is he height. For some of the time t tipper is in the workshop body is up in the fully tipp position and that could mean exceess of 20 ft from grou level.

If there is added to that further 5 ft to 6 ft for a lift a space for ventilation and ting above it the cost of t construction will go up and t heating and lighting charg will also rise. For this reason p or sunken workshops are oured Ideally, these should be at right angles to the outside wall with access from the open area. They should be lit with lights angled up on to the underside of the vehicle with tiled sides and a drained concrete floor sloping slightly towards that outside wall.

Tool kits

Mechanics constantly complain over having to leave and re-enter the pit every time they require a hand tool or small part. There are numerous types of portable tool kits for mechanics on the market and it is not beyond human wit to build in storage space at the end of the pit for tools, olives, unions, nuts, bolts, washers, split pins and the like.

Along the outside wall but inside the workshop and in line with the pits should be located the lubricant storage cabinets with meters and dispensing Hoses and reels on the wall. Access to the cabinets for filling should be provided on the outside of the building.

In this connection too there should be facilities for pump drainage from the vehicle to storage in the oil storage area. This should ideally be no more than 10 ft from the front of the vehicle or pit.

The storage cabinets must be covered by a full-length workshop bench with vices located opposite the end of the pit and storage space for "consumablespares, cleaning materials and the larger hand tools.

Mobile crane

While on tools there was for some time a tendency towards H-beams and pulleys for engine removal. This restricts the engine removal operation to the location of the H-beam. A mobile workshop crane, will cost about the same as two H-beam installations gives much more freedom to the mechanic, it is therefore more productive and makes better use of the workshop space.

By the very nature of their work, tippers are prone to halfshaft problems. This makes trolley jacks and heavy-duty axle stands. essentials. And watch out for pillars.

However, not all equipment can be portable and the wise operator will want power all round the shop. An air-line from the compressor fixed to the wall with a number of quick connection points along it will prove invaluable.

Similarly an electric ring circuit, running parrallel to the air line with plenty of sockets, will supply power and additional trailing lights to most points of the shop. The compressor for the air power might best be located against the retaining wall between the wash bay and the shop.

Obstruction

Because tipper vehicles are normally on short run and tip work and because spare wheels can cause an obstruction on rough sites and reduce payload they are best stored in the workshop — preferably in a security area.

There is no option, however, for the tyre inflation bay. This ideally will be located in the security area, but wherever it is it must be constructed to meet safety requirements.

Just as the entrance to the workshop should be by way of a tunnel or passage which forms the wash bay, so should the exit be functionally designed. A wall similar to that constructed at the wash bay parrallel to it, but at the other end of the workshop will provide a final inspection area. If finance permits a rol road and dynamometer car installed here — but this is perhaps in the luxury class.

The workshop heating matter of choice, but it is ur stood that one choice of en supply is more economical using a variety of sources. would suggest that the choi limited to electricity, but a the architect will be abl measure usage taking acc of heat loss and therefor( timate the running cost c energy supplies.

Heat loss will be substani reduced if the doors are trically operated and if the nel walls are built to roof he Ideally the roof should be and strong enough to taki office block extension in t Roof trusses should be loc so that when a vehicle is or pit the tipped up body will foul the truss.

The local fire officers wil vise on fire prevention ec ment and crime preven officers will advise on sect Neither should be ignored lowing their advice will with the approval of the ins and may result in a red premium.

Only a brave man or a would estimate the cost of a workshop in today's fina climate. Costs must be r sured accurately, but it is wi remember that the SUCCE operator's fleet will grow build for a growing fleet. If cess is not important, d build at all.