Telehoist's tippers get more push

Page 35

Page 36

If you've noticed an error in this article please click here to report it so we can fix it.

IARROGATE this year sees the launch of a new style of body Dr rigid tippers in the 24 to 30-ton bracket. Telehoist, the :heltenham-based hydraulic engineers and body builders vho have introduced it, are these days concentrating on igger bodies and larger rams. To see why and to find out a ttle more about Telehoist and its products. CM paid the ompany a visit.

Telehoist started life as W. V. Jenkins just before the last var. In 1946 it produced the irst underbody tipping ram and Jegan using the trade name -elehoist. Gradually it was aclured by the Midland enginJering firm Wilmot Breeden, Ind is now a separate operating :ompany with the group.

Many of Telehoist's products itill involve hydraulics in one orm or another and one of its )est sellers is the Load Lugger ;kip loader. This, despite the hop in demand from the recently depressed construction ndustry, still accounts for 50 )er cent of all UK sales.

The signs are, however, that hings are improving but felehoist has, nevertheless, iiversified into such specialities 3 s street access platforms and ;cissor lifts for airport use. It )ven makes the -Z wagon' for he Metropolitan Police. This

equipment, the real name of which is the Autoloader, is a device for removing illegally parked cars from the roadway. It works on a similar principle to the load lugger but operates to the side. Double rams allow it to pick up on either side.

Although these applications for Telehoist's technology are interesting, the company is undoubtedly best known for its tipper gear. There are two kinds of front-end ram, the piston type and the displacement type. In general the piston kind, which has the seals on the inside of the ram tube diameters, is suitable for use in countries which don't have abrasive sand.

Dust and grit Those countries that do, require something more, as the seals are more subject to wear and thus leak. For this reason Telehoist developed its metric range of displacement rams. With the displacement ram, the seals are on the outside of the tube and there is always a fine film of oil on the outside of the extending tubes. When the rams are fully extended particles of dust or grit stick to the oil, but are wiped clear by wiper seals as the ram returns. This means that the main seals and gland nut bearing surfaces are protected.

A further advantage of the system is that the tube bearing surfaces are oil lubricated. The construction of the Telehoist metric ram is particularly ingenious. In order to reduce the overall size of the tipper ram and to reduce the cost of the tubing required, Telehoist has cut the annular space between the ram tubes.

By threading the tubes on the outside, it is able to use internally-threaded gland nuts. These are not allowed to touch when the rams are lowered as stop rings are built in. Even these have been specially designed. They are bevelled on the contact edges so that the impact forces tend to push them deeper into their grooves_ Telehoist has spent a lot of time on developing the seals for the metric ram.

Increased life

It uses polyurethane for the wiper seals and the vee pack of main seals has a solid rubber fluid seal backed by a nylon anti-extrusion ring. To reduce friction and increase wear resistance, a laminate of fabric and phenolic resin is employed for the gland bearings.

What does all this mean to the operator? The chief advantage is probably increased life through greater resistance to wear. However, there are others. As the annular spacing has been reduced, the diameter of the larger tubes has been reduced while that of the smaller ones has been increased. This gives the assembly improved resistance to bending when fully extended. In addition, tipping time is speeded up or, alternatively, a smaller-capacity pump can be used. Finally the metric ram gets by with less oil.

The metric ram gets its name from the use of tubes whose outside diameter conform to metric tube sizing. To reduce the raw tubing to the required size quickly, Telehoist uses a machine which has an emery belt. This machine, costing £150,000, is far quicker than an emery wheel and gives the tube a good finish. Threading on the outside is by means of a conventional screw-cutting lathe, although Telehoist had a hand in the design of the tailstock.

To check the internal diameter of the tubing, an American machine is used. This quite simply forces a ball of the right diameter through the tube, thus ensuring a uniform diameter. Telehoist has now become the UK distributor for this machine.

Cheaper

It would be easy to think that most of Telehoist's activities are concerned with hydraulics and their applications. This isn't so. The bigger bodies, mentioned earlier, are becoming more important to the company.

• In conjunction with Magirus Deutz, it developed the Linef low for dump trucks and the stylised body illustrated here is a further development. Telehoist works in steel rather than alloy, as the former makes a body less than half the price of an alloy one.

Also steel is cheaper and easier to repair. Alloy welding is more difficult in a manufacturing plant, anyway, as it can pick up rubbish from the atmosphere, causing bad welds. Telehoist folds its own steel sec tions and has designed its new bodies with a double-skinned top rail to reduce damage from carelessly handled bucket loaders.

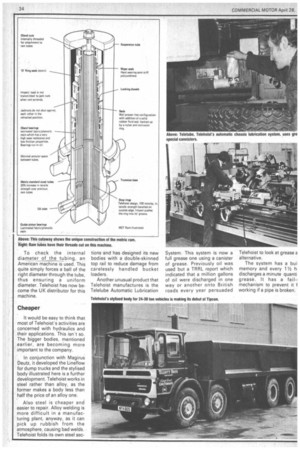

Another unusual product that Telehoist manufactures is the Telelube Automatic Lubrication System. This system is now a full grease one using a canister of grease. Previously oil was used but a TRRL report which indicated that a million gallons of oil were discharged in one way or another onto British roads every year persuaded Telehoist to look at grease a alternative.

The system has a bui memory and every 11/2 h discharges a minute quanti grease. it has a fail mechanism to prevent it f working if a pipe is broken.