AN EFFICIENT BODY-TIPPING APPARATUS.

Page 66

If you've noticed an error in this article please click here to report it so we can fix it.

Details of the Pumping Plant with which a Well-known Manufacturer is Equipping its Tipping Wagons.

THEtipping wagon is steadily increasing in popularity with concerns employing vehicles which transport large quantities of loose materials such as gravel, clinkers, ,steel waste and sand. This is no doubt due to the ease and speed which are obtainable in unloading the contents of this type of vehicle and the minimum amount of manual labour connected with its use, both these factors contributing largely to economy in operating costs.

:Naturally, the machinery which tips the body plays an important part in the working of wagons of this type. Therefore, to ensure the satisfactory

, use of the vehicle as a whole this apparatus must be of efficient design and reliable in operation. Moreover, it must be strongly constructed, as the work which tipping wagons undertake, owing to the nature of the materials which they carry, is 'usually heavy and rough, thus severely trying every part of the vehicle.

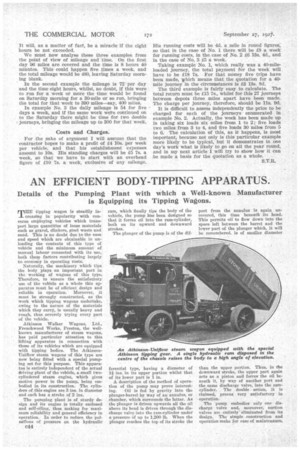

Atkinson Walker Wagons, Ltd., Frenchwood Works, Preston, the wellknown manufacturer of steam wagons, has paid particular attention to this lifting` apparatus in connection with those of its vehicles which are equipped with tipping bodies. The AtkinsonUniflow steam wagons of this type are now being fitted with a special pumping set for this purpose. This apparatus is entirely independent of the actual driving plant of the vehicle, a small twocylindered steam engine, which gives motive power to the pump, being embodied in its construction. The cylinders of this engine are 3 ins. in diameter and each has a stroke of 2 ins.

The pumping plant is of sturdy design and its engine is totally enclosed and self-oiling, thus making for maximum reliability and general efficiency in operation. In order to rednce the pulsations of pressure on the hydraulic ram, which finally tips the body of the vehicle, the pump has been designed so that it forces oil into the ram-cylinder, both on its upward and downward strokes.

The plunger of the pump is of the dif

ferential type, having a diameter of 1gins, in its upper portion whilst that of its lower part is 1 in.

A description of the method of operation of the pump may prove interest ing. Oil is fed by gravity into the plunger-barrel by way of an annulus, or chamber, which surrounds the latter. As the plunger is driven upwards all the ail above its head is driven through the discharge valve into the ram-cylinder undef a pressure Of up to 1,200 lb. When the plunger reaches the top of its stroke the port from the annulus IS again uncovered, this time beneath its head. This permits oil to flow down into the space left between the barrel and the lower part of the plunger which, it will be remembered, is of smaller diameter

than the upper portion. Thus, in the downward stroke, the upper part again acts as a piston and forces the oil beneath it, by way of another port and the same discharge valve, into the ramcylinder. The double action, it is claimed, proves very satisfactory in operation.

The pump embodies only one discharge valve and, moreover, suction valves are entirely eliminated from its design. The simple construction and operation make for ease of maintenance.