SYSTEMATIZING CH 3S MAINTENANCE.

Page 54

Page 55

Page 56

If you've noticed an error in this article please click here to report it so we can fix it.

W hat Constiti Maintenance. I on Lubrication mary of Essen Satisfactory g the Tasks Is. A SumDperations.

TN the maintenance of a commercial vehicle there is obviously room to allow for a vast difference between the ideas of one man' as to what attention • a chassis requires to keep it in good trim and those of another. There is still room, if we ignore the extremes of, on the one hand, no attention at all and, on the other, so much that the vehicle' hardly ever gets on to the road. At the one end of the reasonable scale, for example, we might place a man who, in respect of lubrication, to take one item alone, waits until a joint squeaks before he oils or greases it, and at the other end the man who is really fussy and who is for ever tinkering with his machine, spending far more time tuning it up than he does in driving it.

We can arrive at a proper appreciation of the matter and get this business of care of the chassis in proper proportion, if we look at it for a moment from the manufacturer's point of view—if we consider what he likes to win in the way of a testimonial from a customer concerning one of the vehicles he has made. He likes to be told that a maximum of miles has been covered in a minimum of time, with a minimum of actual expenditure on repairs or renewals of any kind. He can only obtain that when the attention has been enough to avoid the need for any repairs during that period, and when the vehicle has been on the road for the maximum proportion of the time.

Circumstances Alter Cases.

Of course, much depends on circumstances. It may be that the work on which the vehicle is ordinarily engaged is such as to allow plenty of time for the driver' to 'give this extensive attention. An extreme example of this kind is that of a fire engine, which is always so well kept and found, because it is requiredto be on the road only in ease of emergency. It still remains true, however, that' the proper place for an ordinary motor vehicle is the road, and in cases where a vehicle is so little employed that the driver -finds time hang on his hands to such an extent that he must waste it by giving the vehicle superfluous attention, the proper thing to do, is to find work for the vehicle. At the same time it is safe to say that the majority of commercial vehicles is much more likely to suffer from a lack of proper 'attention than from a surfeit of it. • It is impossible to say where maintenance begins.or where it ends, for it goes on throughout the working day. There is no need, however, for the inexperienced owner or driver to alarm himself in thinking over what this might imply. He must first appreciate what is meant by maintenance. Aman is maintaining a vehicle, according to our interpretation of the term, more or less effectively according to the way he drives it. For, since maintenance means keeping the vehicle in running condition and eliminating idling time as the result of mechanical defects, a man who is a careful driver is maintaining his vehicle by so operating it that it keeps in efficient condition-for the maximum period without needing attention on the part Of any other person. This maintenance begins each day when, amongst other daily operations which we shall shortly enumerate, he cheeks the amount of water in the radiator and oil in the engine sump. It is neglected whenever he omits to observe these precautions.

All maintenance operations must be performed at regular intervals. Some are needed daily, others weekly, some monthly and others, again, quarterly, whilst there are things which need to be done at even longer intervals. The work is made easier and is more readily performed if it be systematized.

The scheme we have in mind is based on the general practice amongst manufacturers of recommending that certain lubricating operations be carried out at specific intervals. We take a lubricating chart as a basis

c32 and increase its scope so that it will include the other mechanical attentions which the chassis needs, if it is to be kept fit.

The individual owner or driver can easily draw up his own scheme, basing it upon the lubrication chart which is issued by the manufacturers of his particular vehicle.. These charts do not differ greatly one from another, except as regards one rather important matter. In some the intervals between operations are reckoned in time; in others, according to the mileage. We prefer the former,and suggest that wherever a chart is based on mileage intervals it should be . altered to the other form. We are aware that, strictly speaking, the division according to mileage is more correct, but prefer the other, which can be made sufficiently accurate for all practical purposes, because it is much. More conVenient. In Making the alteration it may be presumed roughly that about 60 or sO miles is a day, 250 to 300 miles a week, 1,000 a month, and 2,000 miles and upwards a quarter.

The first thing to do is to make out lists of daily, weekly, monthly and quarterly operations according to the lubrication chart, adding to each .particulars of the mechanical maintenance operations which are due for per formance at about the same or equivalent intervals. The list of lubricating operations due each day according to the lubrication chart of a well-known commercial vehicle is as follows:— Grease the shackle-pins, clutch spigot, clutch-withdrawal shaft, sliding end of clutch shaft, brake-shoe pivot pins, brake camshafts, brake-gear -pivot pins, brake cross-shafts, change-speed shafts and the shaft NA hich carries the pedals.

Oil the brake and change-seed pins and joints. In addition check and replenish oil in engine case.

The daily maintenance operations are few. To check the water level in the radiator and replenish is one; to examine the tyres and remove any small flints is the other.

The weekly operations are as follow:—

'Grease the fan and water-pump bearing and the joints on the propeller shaft and oil the clutch-stop anchor bolt. . • Each week there are certain nuts about the chassis to which a spanner should be applied; on lighter vehicles, for example, with detachable wheels, the nuts holding these wheels in place should have that attention. If pneumatic tyres be fitted the air Pressures should be tested and if .necessary brought up to standard. For the first few months of the vehicle's life the spring clips should be tightened just as frequently. The battery should be examined to see if it needs the addition of distilled water.

Each month, according to the particular chart we have before us, the clutch-withdrawal lever pins should be oiled and the level of the lubricant in the gearbox examined and, if necessary, replenished. At the same time the steering box should be refilled with grease, if this be found necessary.

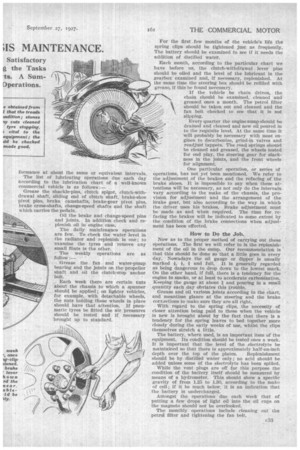

If the vehicle be chain driven, the chain should be examined, cleaned and

greased once a month. Tile petrol filter should be taken out and cleaned and the fan belt checked to see that it is not slipping.

Every quarter the engine sump should be drained and cleaned and new oil poured in to the requisite level. At the same time it will probably be necessary with most engines to decarbonize, grind-in valves and readjust tappets. The road springs should be cleaned and greased, the wheels tested for end play, the steering gear for slackness in the joints, and the front wheels for alignment.

One particular operation, or series of operations, has not yet been mentioned. We refer to the adjustment of the brakes and the refacing of the brake shoes. It is impossible to say when these at tentions will be necessary, as not only do the intervals vary according to the make of the chassis, the pro vision for adjustment and the arrangement of the brake gear, but also according to the way in which the driver uses his brakes. Brake adjustment must be made as and when required. The time for refacing theY brakes will be indicated to some extent by the condition of the brake connections when adjustment has been effected.

How to Do the Job.

Now as to the proper method of carrying out these operations. The first we will refer to is the replenishment of the oil in the sump. Our recommendation is that this should be done so that a little goes in every day. Nowadays the oil gauge or dipper is usually marked Jr, and full. It is generally regarded as being dangerous to drop down to the lowest mark. On the other hand, if full, there is a tendency for the engine to smoke, or at least to accelerate carbonization, Keeping the gauge at about / and pouring in a small quantity each day obviates this trouble.

Grease and oil various joints according to the chart, and meantime glance at the steering and the brake comections to make sure they are all right.

With regard to the spring clips, the necessity of closer attention being paid to these when the vehicle is new is brought about by the fact that there is a tendency for the spring leaves to bed together more closely during the early weeks of use, whilst the clips themselves stretch a little.

The battery, where used, is an important item of the equipment. Its condition should be tested once a week. It is important that the level of the electrolyte be maintained so that there is approximately half-an-inch depth over the top of the plates. Replenishment should be by distilled water only; no acid should be added unless some of the electrolyte has been spilled.

While the vent plugs are off for this purpose the condition of the battery itself should be measured by means of a hydrometer. This should show a specific gravity of from 1.25 to 1.30, according to the make of cell; if it he much below, it is an indication that the battery is undercharged.

Amongst the operations due each week that of putting a few drops of light oil into the oil cups on the magneto should not be overlooked.

The monthly operations include cleaning out the petrol filter and tightening the fan belt. One of the most frequent causes of a hot engine, and one which is seldom suspected, is a slipping fan belt. It is no trouble to look at this once a month.

On chain-driven vehicles the driving chains should be examined, cleaned and greased. The examination is necessary to ascertain if any excessive stretch has taken place. This should be tested by placing the chain at full length on the ground, fixing one end and stretching it as far as possible. Mark on the ground the point to which the free end reaches; now compress the chain as far as it will go, and measure the distance from the free end to the mark already made. If that distance exceeds 21 ins, the chain should be replaced with a new one, and in cases where a vehicle is doing considerable mileage and it is observed that the amount of stretch is approaching 21 ins., a spare chain or chains should be ordered for replacement purposes against the time when the limit of permissible stretch is reached. As the chain stretches, and before the elongation is so much as to cause anxiety, it will be necessary, in order to get the proper adjustment, to shorten the chain by half a link.

When this examination and, if necessary, addition of half a link have been made, the chains should be thoroughly washed in paraffin and then steeped for several hours in hot grease.

Whenever any adjustment of the length of the driving chains has been made it is imperative, before using the wagon again, to readjust the brake connections.

The list of quarterly operations is a formidable one, not only in length, but as regards the importance of the operations which must be performed. We have set down decarbonizing, valve grinding and tappet adjustment as being one series. .At the same time the engine sump must be drained, _ cleaned as far as possible, and replenished. The carburetter and petrol pipe should, be taken down and "cleaned, the magneto attended to, its contact breaker adjusted and the distributor cleaned. The dynamo and, if fitted, starter motor should also have attentior),I the gearbox • and rear axle case may just as well be emptied and

• refilled at the same time as the• engine, whilst if the water which is usually put into the radiator has a tendency to cause furring of the passages it should be emptied and its place temporarily taken by .a strong solutioll of caustic soda, which should, however, subsequently be swilled out before the vehicle is put

into commission again, otherwise the Metal will corrode.

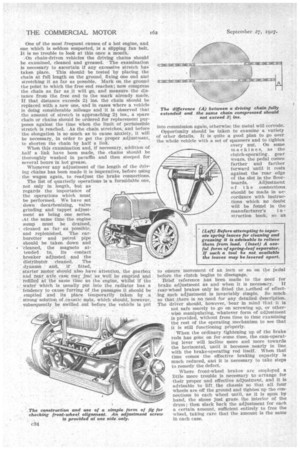

Opportunity should be taken to examine a variety of other details. It is quite •a good plan to go over the whole vehicle with a set of spanners and to tighten every nut. On some machines, as the clutch-operating, gear wears, the pedal comes farther and farther forward until it rests against the rear edge of the slot in the floor boards. Adjustment of the connections. should be made in accordance with instructions which no doubt will be found in the manufacturer's i a struction book, so as to ensure Movement of an inch or so on the pedal before the clutch begins to disengage.

Brief reference has been made to the need for brake adjustment as and when it is necessary. If rear-wheei brakes only be fitted the taethod of effecting such adjustment is invariably simple. So much so that there is no need for any detailed description. The driver should, however, bear in mind that it is not safe merely to go on screwing up, or otherwise manipulating, whatever form of adjustment is provided, without from time to time examining the rest of the operating mechanism to see that it is still functioning prbperi.y.

When the ordinary tightening up of the brake rods has gone on for -some time, the cam-operating lever will incline more and more towards the horizontal, until it becomes nearly in line with the brake-operating rod itself. When that time comes the effective braking capacity is Much reduced, and it is necessary to take steps to remedy the defect.

Where front-wheel brakes are employed a little more trouble is necessary to arrange for their proper and effective adjustment, and it is advisable to lift the chassis so that all four wheels are off the ground and tighten up the connections to each wheel until, as it is spun by hand, the shoes just graze the interior of the drum; then slack back the adjustment far each a certain amount, sufficient entirely to free the wheel, taking care that the amount is the same in each case.