A DE ICE FOR TESTING BRAKING EFFICIENCY.

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

An Automatic Contrivance in which the Retarding Effect of the Causes a Ball to Run up an Enclosed Inclined Plane.

MHE need for the utmost care in maintaining the _L brakes in good condition, particularly on passengercarrying vehicles, has often been stressed in this journal. One of the difficulties experienced by those in charge of fleets of vehicles, however, is that there is no generally accepted standard of braking; in fact, the retarding effect produced by the brakes is so difficult to mea ure with anything but complex scientific apparatus that the criterion is usually simply the personal judgtent Of the driver or maintenance engineer. To a tempt to: measure stopping distances is usually found to be very unsatisfactory as many variables preveilt accurate results from being obtained ; in any case, an accurate speedometer, skilful driver, level road and some means for marking the point at which the brakes were applied are all essentials.

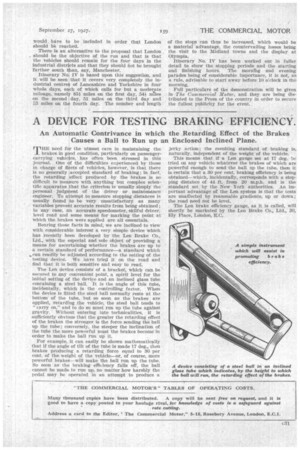

Bearing these facts in mind; we are inclined to view with considerable interest a very simple device which has recently been developed by the Len Brake Co., Ltd., with the especial and sole object of providing a means for ascertaining whether the brakes are up to a certain standard of performance—a standard which wean readily be adjusted according to the setting of the testing device. We have tried it on the road and find, that it is both sensitive and_ easy to read.

The Len device consists of a bracket', which can be secured to any convenient point, a spirit level for the initial setting of the device and an inclined glass tube containing a steel ball. It is the angle of this tube, incidentally, which is the controlling factor. When the device is fitted the steel bail normally rests at the bottom of the tube, but so soon as the brakes are applied, retarding the vehicle, the steel ball tends to " carryt on," and to do so must run up the tithe against gravity. Without entering into technicalities, it is sufficiently obvious that tile greater the retarding effect of the brakes the stronger is the force sending the ball up the tube ; conversely, the steeper the inclination of. the tube the more powerful must the brakes become in order to make the ball run up it.

For example, it can easily be shown mathematically that if the angle of tilt of the tube is made 17 deg., then brakes producing a retarding force equal to 30 per cent. of the weight of the vehicle—or, of course, more powerful brakes—will make the ball run up the tube. So soon as the braking efficiency falls off, the ball cannot be made to run up, no matter how harshly the pedal may be operated in an attempt to produce a jerky action; the resulting standard of braking is, naturally, independent of the weight of the vehicle.

This means that if • a Len gauge set at 17 deg, be tried on any vehicle whatever the brakes of Which are powerful enough to send the ball up the tube, then it is certain that a 30 per cent. braking efficiency is being obtained— which, incidentally, corresponds with a stopping distance of 44 ft. from 20 m.p.h. and is the standard set by the New York authorities. An important advantage of the Len system is that the tests -are unaffected, by reasonable gradients, up or 'down; the road need not be level.

The Len brake efficiency gauge, as it is called, will shortly be marketed by the Len Brake Co., Ltd., 30, Ely Place, London, E.C.