A VARIABLE GEAR WITH FRICTION . PINIONS.

Page 50

If you've noticed an error in this article please click here to report it so we can fix it.

Details of an Interesting Transmission Mechanism which Gives Infinite Speed Variations Between Zero and the Highest Ratio.

A. PARTICULARLY interesting form of variable-speed gear, . and one which is remarkably simple both in its conception and design, is the Keenok, produced by the Keenok Co., Ltd., 1-9, Eleanor Street, Bow, London, E.3.

The basis of the gear is the Keenok pinion. This is a transmission member which is claimed by the company to combine the action of a friction drive with the positiveness of-a spur gear, and it is stated that it can be used in many mechanisms for replacing tooth gearing.

The pinion will mate with the face of a disc or the periphery of a truly turned wheel, and the drive positive because, by reason of its construction, the more load that is Put upon it the more is the pressure between the contacting surfaces, thus preventing slipping. At the same time, the pressure is said not to be excessive, because it is always only just sufficient to prevent slip; thus, if the load be light the pressure will also be light. In a variable drive of the Keenok type, in which a disc 41 ins, in diameter drove a Keenok pinion 41 ins. in diameter, the two being immersed in oil, a load of 300 in.-lb. was applied to the variable shaft, and no trace of slip occurred. The load on the variable shaft was then suddenly increased to approximately 1,000 in.-lb., with the result that the 9 h.p. D.C. electric motor was immediately stopped.

We examined the pinion and disc of a gear which had run for three months during 81 hours each day under the full rated load. No

c98 .

diminution in the diameter of the pinion could be detected by the micrometer, and the surfaces, both of the pinion and of the disc, were merely polished.

The speed variation which can be obtained with this form of friction drive is largely dependent upon the diameters of the two members. With a 5-in. disc and a 41-in. pinion it has been found practicable to obtain ratios from 1-1 to 1-10 on the constant-speed shaft. With larger members correspondingly greater variation is possible.

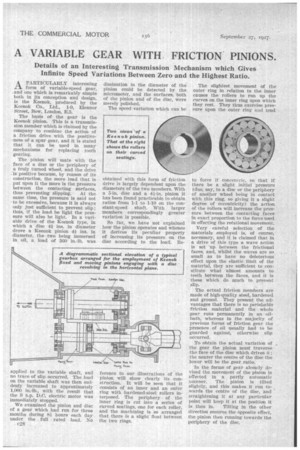

So far, we have not explained how the pinion operates and whence it derives its peculiar property of increasing its pressure on the disc according to the load. Re ference to our illustrations of the pinion will show clearly its construction. It will be seen that it consists of an inner and an outer ring with hardened-steel rollers interposed. The periphery of the inner ring is cut into a series of curved seatings, one for each roller, and the machining is so arranged that there is a slight float between the two rings. • The slightest movement of the outer ring in relation to the inner causes the rollers to run up the curves on the inner ring upon which they rest. They thus exercise pressure upon the outer ring and tend to force it concentric, so that if • there be a slight initial pressure (due, say, to a disc or the periphery of another wheel being in contact with this ring, so giving it a slight degree of eccentricity) the action of the rollers vvill.increase the pressure between the contacting faces In exact proportion to the force used in effecting the rotational movement.

Very careful selection of the materials employed is, of course, necessary, and it is claimed that in a drive of this type a wave action is set up between the frictional faces; and, whilst the waves are so small as to have no deleterious effect upon the elastic limit of the material, they are sufficient to Constitute what almost amounts to teeth between the faces, and it is these which do much to prevent slip.

The actual friction members are made of high-quality steel, hardened and ground. They present the advantages that there is no perishable 'friction material and the whole gear runs permanently in an oilbath, whereas in the majority of previous forms of friction gear the presence of oil usually had to be guarded against, otherwise slip occurred.

To obtain the actual variation of the gear the pinion must traverse the face of the disc which drives it; the nearer the centre of the disc the lower will be the gear ratio.

In the forms of gear already devised the movement of the pinion is effected in a partly automatic manner. The pinion is tilted slightly, and this makes it run towards the centre of the disc, and straightening it at any particular point will keep It at the position it is then in. Tilting in the other direction ensures the opposite effect, the pinion then running towards the periphery of the disc.