MORE NEW MORRIS-COMMERCIALS

Page 77

Page 78

Page 79

If you've noticed an error in this article please click here to report it so we can fix it.

Full Particulars of a Bus Chassis to Carry Double-deck Body work—and a 4-ton Goods Vehicle

TIIE enterprise shown in the past by Sir William Morris is being steadily, maintained for, as the leading personality of Morris Commercial .Cars, Ltd., Soho, Birmingham, he is about to enter two new fields of activity. Both relate to large vehicles, one being chiefly the concern of municipal-transport undertakings, whilst the other has to do with all classes of operator using medium-capacity vehicles.

The two new machines are a fourwheeled bus chassis, for double-deck bodies, to be known as the Imperial, whilst the other is a 4-ton goods chassis having a four-cylindered engine and of exceptionally sturdy build. In the interests of clearness we will describe the two vehicles separately, although the power units are identical in design, save for the fact that one (the passenger-vehicle unit) has six cylinders.

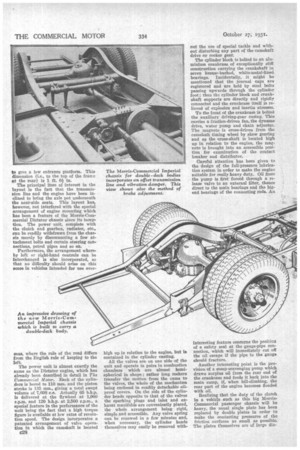

With a wheelbase of 16 ft. 1 in. the passenger chassis has an overall length of 25 ft. 6a ins., of which 20 ft. SI; ins. is body space ; forward control is, of course, employed. Track dimensions for the front and rear wheels, are respectively 6 ft la in. by 5 ft. -10i ins., and the chassis has been planned so that the overall width is within the 7-ft. 6-in. mark. Other interesting dimensions concern the width of the frame, which measures 3 ft. at the front and 3 ft. 114 ins, at the rear, whilst the frame height, when the vehicle is loaded, is 1 ft. 9 ins. The rear part of the frame aft of the axle kickup is much lower than the portion between the axles, to give a low entrance platform. This dimension (i.e., to the top of the frame at the rear) is 1 ft. Oi in.

The principal item of interest in the layout is the fact that the transmission line and the engine have been inclined to bring the axle pot underneath the near-side seats. This layout has, however, not interfered with the special arrangement of engine mounting which has been a feature of the Morris-Commercial Dictator chassis since its inception. The power unit, complete with the clutch and gearbox, radiator, etc., can be readily withdrawn from the chases merely by disconnecting a few attachment bolts and certain steering connections, petrol pipes and so on.

Furthermore, the arrangement whereby left or right-hand controls can be Interchanged is also incorporated, so that no difficulty should arise on this Wore in vehicles intended for use over

seas, where the rule of the road differs from the English rule of keeping to the left.

The power unit is almost exactly the same as the Dictator engine, which has already been described in detail in The Commercial Motor. Each of the cylinders is bored to 110 ram. and the piston stroke is 135 mm., giving a total swept volume of 7,698 e.e. Actually 65 b.h.p. Is delivered at the flywheel at 1,000 r.p.m. and 120 b.h.p. at 2,500 r.p.m., special feature in the performance of the unit being the fact that a high torque figure is available at low rates of revolution speed. The design incorporates a patented arrangement of valve operation in which the camshaft is located C28

high up in relation to the engine, but is contained in the cylinder casting.

All the valves are on one side of the unit and operate in pairs in combustion chambers which are almost hemispherical in shape ; rather long rockers transfer the motion from the cams to the valves, the whole of the mechanism being enclosed in readily detachable oilproof covers. On the side of the cylinder heads opposite to that of the valves the sparking plugs and inlet and exhaust manifolds are conveniently placed, the whole arrangement being rigid, simple and accessible. Any valve spring can be renewed in a few minutes and, when necessary, the cylinder heads themselves may easily be removed with out the use of special tackle and without disturbing any part of the camshaft drive or rocker gear.

The cylinder block is bolted to an aluminium crankcase of exceptionally stiff construction carrying the crankshaft in seven bronze-backed, white-metal-lined bearings. Incidentally, it might be mentioned that the journal caps are registered and are held by steel bolts passing upwards through the cylinder foot; thus the cylinder block and crankshaft supports are directly and rigidly connected and the crankcase itself is relieved of explosion and inertia stresses.

To the front of the crankcase is bolted the auxiliary driving-gear easing. This carries a friction-driven ftm, the dynamo drive, water pump and chain adjuster. The magneto is cross-driven from the camshaft timing wheel by skew gearing and as the cross-shaft is located high up in relation to the engine, the magneto is brought into an accessible position for examination of the contact breaker and distributor.

Careful attention has been given to the design of the full-pressure lubrication system in order to make the engine suitable for really heavy duty. Oil from the pump is first forced through a release valve to an external filter, thence direct to the main bearings and the bigend bearings of the connecting rods. An

Interesting feature concerns the position of a safety seal at the gauge-pipe connection, which will immediately cut off the oil escape if the pipe to the gauge should fracture.

Another interesting point is the provision of a sump-scavenging pump which draws surplus oil from the rear end of the crankcase and feeds it back into the main sump, if, when hill-climbing, the rear part of the engine becomes flooded with oil.

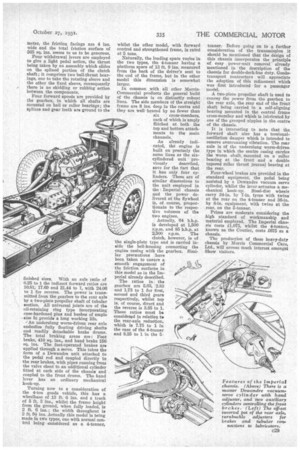

Realizing that the duty of the clutch in a vehicle such as this big MorrisCommercial passenger chassis will be heavy, the usual single plate has been replaced by double plates in order to make the contacting pressures of the friction surfaces as small as possible. The plates themselves are of large din meter, the friction facings are 4 ins. wide and the total friction surface of 565 sq. ins. seems to us to be generous.

Four withdrawal levers are employed to give a light pedal action, the thrust being taken by an assembly which slides on the splined portion of the clutch shaft ; it comprises two ball-thrust bearings, one to take the rotating sleeve and the other the fixed sleeve, consequently there is no skidding or rubbing action between the components.

Four forward speeds are provided by the gearbox, in which all shafts are mounted on ball or roller bearings; the splines and gear teeth are ground to the finished sizes. With an axle ratio of 6.25 to 1 the indirect forward ratios are 10.81, 17.69 and 31.44 to 1, with 24.06 to 1 for reverse. The power is transmitted from the gearbox to the rear axle by a two-piece propeller shaft of tubular section. All universal joints are of the oil-retaining ring type incorporating east-hardened pins and bushes of ample size to provide a long working life.

An underslung worm-driven rear axle embodies fully floating driving shafts and readily detachable brake drums. The total braking areas are: Foot brake, 410 sq. ins., and hand brake 156 sq. ins. The foot-operated brakes are applied through a servo. This takes the form of a Dewandre unit attached to the pedal rod and coupled directly to the rear brakes, with pipes running from the valve chest to an additional cylinder fitted at each side of the chassis and coupled to the front drums. The hand lever has an ordinary mechanical hook-up.

Turning now to a consideration of the 4-ton goods vehicle, this has a wheelbase of 13 ft. 6 ins, and a track of 5 ft. 3 ins., whilst the frame height from the ground, when fully loaded, is 2 ft. 6 ins.; the width throughout is 2 ft. 91 ins. Actually this model is being made in two types, one with normal control being 'considered as a 4-tanner, whilst the other model, with forward control and strengthened frame, is rated at 5 tons.

Naturally, the loading space varies in the two types, the 4-tonner having a platform space of 13 ft. 9 ins, measured from the back of the driver's seat to the end of the frame, but in the other model this dimension is somewhat larger.

In common with all other MorrisCommercial products the general build of the chassis is on distinctly robust lines. The side members of the straight frame are 8 ins, deep in the centre and they are well braced by no fewer than six • cross-members, each of which is 'amply flitehed at both the top and bottom attachments to the main channels.

As already indicated, the engine is built on precisely the same lines as the sixcylindered unit pre viously described, save for the fact that it has only four cylinders. These are of similar dimensions to the unit employed in the Imperial chassis and the power delivered at the flywheel is, of course, proportionate to the respective volumes of the two engines.

Actually, 64 b.h.p, is developed at 1,500 r.p.m. and 85 b.h.p. at 2,500 r.p.m. The clutch, however, is of the single-plate type and is carried inside the bell-housing connecting the engine casing with the gearbox. Similar precautions have been taken to ensure a /smooth engagement of the friction surfaces in this model as in the Imperial already described.

The ratios in the gearbox are 5.03, 2.83 and 1.73 to 1 for first, second and third gears respectively, whilst top is, of course, direct and the reverse is 3.85 to 1. These ratios must be consiclesed in relation to the rear-axle reduction, which is 7.75 to 1 in the case of the 4-tonner and 8.25 to 1 in the 5

tanner. Before going on to a further consideration of the transmission it should be mentioned that the design of this chassis incorporates the principle of easy power-unit removal already mentioned in the description of the chassis for double-deck-bus duty. Goads' transport contractors will appreciate the adoption of this refinement which was first introduced for a passenger model.

A two-piece propeller shaft is used to convey the power from the gearbox to the rear axle, the rear end of the front shaft being carried in a self-aligning bearing mounted in the central frame cross-member and which is lubricated by one of the grouped nipples in the centre of the chassis.

It is interesting to note that the forward shaft also has a torsional oscillation damper which is intended to remove overrunning vibration. The rear axle is of the underslung worm-driven type in which the centre casing carries the worm shaft mounted on a roller bearing at the front and a double tapered roller thrust journal bearing at the rear.

Four-wheel brakes are provided in the standard equipment, the pedal being assisted by a Dewandre vacuum servo cylinder, whilst the lever actuates a mechanical hook-up. Steel-disc wheels carry 34-in. by 7-in. tyres with twine at the rear on the 4-tanner and 36-in. by 8-in, equipment, with twins at tho rear, on the 5-loaner.

Prices are moderate considering the high standard of workmanship and material employed. The Imperial chassis costs £1,075, whilst the 4-tanner, known as the Courier, costs 1675 as a chassis.

The production of these heavy-duty chassis by Morris Commercial Cars, Ltd., will arouse much interest amongst Show visitors.