CHASSIS DEVELOPME NCE THE 19231 SHOW.

Page 30

Page 31

Page 32

If you've noticed an error in this article please click here to report it so we can fix it.

Although Chiefly Apparent in the Pa in Every Direction, the Objects IodeIs there has been Steady Progress 'ety and Economy in Operation.

THE 1925 Commercial Vehicle Exhibition will mark a definite and satisfactory stage in the progress towards perfection of the commercial vehicle. It is only the few who have had access to the works of the makers and have been able to inspect the new chassis who can as yet obtain a true conception of the remarkable advances which have been made. True, the majority of these are, at the moment, in respect of passenger vehicles, but it will not be long before more attention is given to those built primarily for goods transport ; in fact in certain makes this is already taking place, apart from small improvements which are a natural sequence to extensive operation.

• The leading changes being in passenger vehicles, it is only meet that we should deal with these first. Certainly, the most general and striking is the sudden and almost startling separation of the passenger chassis from that intended for goods. Not many months ago the number of models built solely for the passengervehicle market could easily have been counted on the lingers of one hand. In fact, they would not have required so many as that, and those marketing chassis almost always gave the capacity as being so many tons or people and were explicit in their statements as to the suitability of these chassis for their dual roles.

For many years this journal has consistently pointed out the need for treating the two classes of work as two distinct problems necessarily having different solutions, and has deprecated the employment, on comparatively high-speed bus and coachwork, of goods chassis, but • slightly modified as to springing and sometimes—but not always----gear ratios. Foreign manufacturers recognized this need long before those here, with the natural result that their products began to oust the camouflaged lorry, particularly in difficult parts of the country where hills abound, and we are extremely pleased that at last there are available suitable chassis of British design and manufacture, some embodying features so modern that they have advanced at one step from the rear to the forefront.

What are the Innovations ?

What, it may be asked, are these striking innovations Foremost in our opinion is the general lightening of passenger chassis to permit the more efficient employment of pneumatic tyres, and with this may be combined lighter and better-balanced engines, capable of reaching far higher speeds without thrashing, excessive vibration and noise. Next is the almost general lowering of platform heights, which permits quick steering and the rounding of corners at a fair speed without that objectionable and dangerous rolling which used to occur so often. Another of great importance is the provision of far more powerful brakes, many designed to act on all wheels and smile servo-operated or assisted.

Even in the materials employed in the building of the chassis considerable improvements have been effected. Alloy steels are used to an increasing extent. Cast flywheels, which are now proving unsuitable for the higher engine speeds, and have even been known to burst, are being replaced by the forged steel variety. Aluminiumalloy pistons are being used more widely, and in some engines even duralumin connecting rods are embodied. Of Course, none of these improvements is confined entirely to the passenger vehicles, many being embodied also in those intended for goods.

With higher engine speeds many lubricating systems have had to be overhauled, for some which proved perfectly satisfactory on low-speed lorries could not meet the more modern demands. Most engines now have either complete pressure feed or combined pressure and splash.

The single-disc type of clutch is rapidly coming to the fore, for it is simple, efficient and seldom requires adjustment, whilst it gives consistent service without developing slip or becoming fierce. Where cone-type clutches are retained these are usually faced with woven asbestos material in place of leather.

ImProvements in gearboxes are perhaps not so apparent as real; ground teeth on the pinions are now P32 almost universal. Gear-locking devices within the cases have been fitted where formerly absent, and where it has not been found possiEle to reduce the length of the shafts to an appreciable extent the shafts are now provided with centre bearings. Accessibility has received attention, and in most chassis the gearbox can be dropped without disturbing other units or the body, except, of course, where engine and gearbox are mounted together. Covers have been made larger, and in at least one instance the cover has been transferred to the side to facilitate inspection of the pinions and adjustment of the gear-shifting mechanism.

A decided advance has been made in connection with the actual control of the gears, the development being towards the elimination of unnecessary and complicated parts and the avoidance of too many joints, the wearing of which may materially affect the proper meshing of the gears.

The bunting tooth principle is now almost universally employed in fixing gear ratios, as this prevents any small defects in one tooth repeatedly coming into contact with the same sets of teeth on the wheel with which it is meshing.

A lot of work has been carried out in an endeavour to reduce gearbox noises. In a recent instance it was discovered that the fitting of a joint of the Hardy type between the power unit and the gearbox had a great influence in arresting gear hum, for the reason that the flexible joint appeared to absorb wholly or partially those minor engine vibrations which tend to cause what • almost amounts to a chatter in the teeth.

In our opinion the solution of the drumming in enclosed bodies caused by chassis vibrations can only effectively be damped byseparating body and chassis by shock and sound-insulating material, no metallic

contact being permitted at all between body and chassis. This is being done with great success in certain instances, particularly in bus work, the absorption material employed being usually rubber, although thero is a possibility that bodies may be hung on special fabric dampers.

With higher vehicle speeds, the question of providing well-balanced and truly running propeller shafts has assumed great importance. Even well-balanced shafts,, I! of small diameter, may develop whip, caused, perhaps, in the first place by a quick movement of the chassis on a rough road and accentuated by centrifugal force. This not only results in a most unpleasant vibra, Lion, but may even cause the shaft to tear away from its universal joints, and, whirling round, to cut through the body. Several instances of this have actually occurred recently.

The solution is to provide propeller shafts, preferably of the tubular type, having a large diameter, but of comparatively light weight, and to useivvith the shafts universal joints which are self-centring.

In the case of flexible fabric joints, several makerS 'have adopted centring devices of what may be called the block and die type, so that centrifugal force does not have the effect of making the shaft eccentric in relation to its joints. • Final drive is still a matter of much controversy. So far the worm is still holding its own, and it will probably retain a large measure of popularity in the future, but, in our opinion, there will be gains in other directions.

The double-deduction axle, if of good design, can be made fairly light; almost noiseless, and of small dimensions. The latest type developed has spiral-bevel gearing for• the first reduction, followed by double helical gears, both of which forms are almost completely silent in operation. An axle of this type can be made considerably less in overall dimensions than even the worm, the only increase in size is usually in the horizontal plane ; vertically it allows ample clearance from the ground and for the movement of the axle towards the body. The it-tatter of unsprung weight is not of quite such vital importance when pneumatic tyres are fitted, as these can be looked upon as being air springs. "

A certain amount of attention has been turned to the dual-type axle having the final drive by internal gears, and whilst this has proved fairly satisfactory in certain instances, it is expensive to manufacture, must he capable of accurate adjustment and is hardly suitable for the more powerful engines which are now increasing in number.

As if is not long ago since we dealt very fully with the question of rear-axle design, we will not at the moment enter into further details.

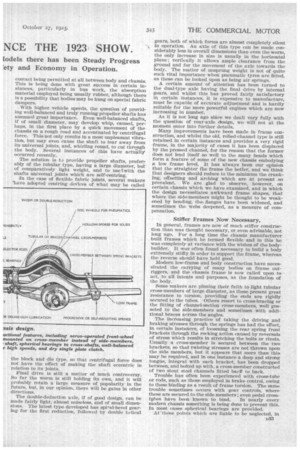

Many improvements have been made in frame construction, and whilst the old, rolled-channel type is still retained in certain instances and provides a very rigid -frame, in the majority of cases it has been displaced by the pressed channel, for the reason that the former• does not lend itself so well to the many bends which form a feature of some of the new chassis embodying n low frame level. It has always been our opinion that the straighter the frame the better, and we think that designers should reduce to the minimum the cranking, offsetting and arching which are at present so prevalent. We are glad to observe, however, on certain chassis which we have examined, and in which the design necessitates awkward frame shapes, that where the side-members might be thought to be weakened by bending, the. flanges have been widened, and sometimes the webs deepened, as a measure of compensation.

Stiffer Frames Now Necessary,

In general, frames are now of much stiffer construction than was thought necessary, or even advisable, not long ago. For a long time the chassis manufacturer built frames which he termed flexible and in this he was completely at variance with the wishes of the bodybuilder. It was often found necessary to build a body extremely stiffly in order to support the frame, whereas the reverse should have held good.

Modern low-frame and body construction have necessitated the carrying of many bodies on frame outriggers, and the chassis frame is now called upon to act, to all intents and purposes, as the foundation of the body.

Some makers are pinning their faith to light tubular cross-members of large diameter, as these present great resistance to torsion, providing the ends are rigidly secured to the tubes. Others resort to cross-bracing or the fitting of channel-section cross-members, well gusseted to the side-members and sometimes with additional braces across the angles.

The increasing practice of taking the driving and braking stresses through the springs has had the effect, in certain instances, of loosening the rear spring front brackets through the rocking action caused by reversals of stress which results in stretching the bolts or rivets. Usually a cross-member is secured between the two brackets, so that twisting stresses are not thrown upon the side members, but it appears that more than this may be required, and in one instance a deep and strong . tongue, integral with each bracket, has been dropped between, and bolted up with, a cross-member constructed of two stout steel channels fitted back to back.

• Trouble has often been experienced with cross-tube or rods, such as those employed in brake control, owing to these binding as a result of frame torsion. The same trouble sometimes occurs with gear controls, where these are secured to the side members ; even pedal crosstphes have been known to bind. In nearly every modern chassis something is being done to prevent this. In most cases spherical bearings are provided.

At those points which are liable to be neglected, in D33 some instances, the bushes have been replaced by bearings which do not require lubrication, and are made of such material as that provided by Perak), Ltd., which is quite satisfactory where the movement is not excessive and the bearing speed is slow.

Almost all chassis are now equipped -with some form of oil or grease-gun lubrication, and a few are notable

for the provision of totally enclosed bearings, apart from those in the engines, running in oil-baths or having wick feeds, this applying to universal joints, cross-tubes, sub-frames, etc.

Even the radiator, apart from mere improvements in Its appearance, has received attention in the matter of design, and, perhaps, of more importance, in its mounting. The familiar type with the cast-aluminium header, bottom tank and side brackets is retaining its

popularity, but experiments are now being made with•

radiators constructed in pressed steel and built up on the same principle as those of cast-aluminium. In

others, the core proper is surrounded by a steel cowl, the core, in some cases, being mounted on the sub-frame with the engine.

Much trouble has been experienced with straining and consequent leakage through frame movement, and it is somewhat surprising that more radiators are not mounted on the front cross-member, either through rubber pads or through the medium of trunnion brackets. With a strongly constructed cross-bearer, there is practically no possibility of torsional strains occurring.

For coachwork, where appearance is a matter of great importance, some of the newest radiators are being constructed in white-metal taking a• high polish, and there is a general tendency towards more artistic shapes.

Wheels of the disc type are gaining a large number of adherents, chiefly for the reason of the increasing employment of pneumatic tyres, for which these wheels are eminently suitable. They present the advantage that they can easily be dished to afford a close approach to centre-point steering, and where front-wheel brakes are fated the brake drums can be neatly ensconced inside the rims and almost flush.

Where solid tyres are employed, the majority of wheels are of the cast, hollow-spoked type, these wheels being almost invariably cast from the centre outwards to avoid unequal cooling in the rims.

For a time it appeared that there would not be many alterations in brake design, but during the past few months the results of years of experimenting have been brought to light, and a great many of the vehicles which will he exhibited at Olympia will be equipped with brakes on all wheels, some of these being servo-operated, in two or three cases, this being effected by coupling the front-wheel brakes to Merocking anchorage of the transmission brake shoes—a system which presents advantages in that the front brakes cannot possibly be applied until alter that on the transmission, this lag assisting in the prevention of front-wheel skids.

Many improvements have been made in the matter of springing. There are, of course, notable designs in which the springing is self-adjusting to load, either through the effective spring length being reduced as the load increases, or by the use of auxiliary plates which only make contact with the main plates when the spring is almost flattened out ; but, apart from seat alterations, there have been numerous smaller improvements which, in the mass, have all tended towards better springing. Eyes forged solid with the plates instead of being rolled, nibs to locate the plates instead of weakening holes for bolts, clip-eyes formed in one with the spring leaves, and divided top leaves to which the axle is rigidly secured, and thereby enabled to take the braking and driving stresses without slipping along the springs, have all participated in the bettering of efficiency.

To our mind, one of the weakest points' in the average engine is the drive to the fan. Link belts have done much to reduce the trouble, but it would be far more satisfactory if the fan were positively driven, and this is actually being done now in several engines. In such cases care must be taken that the fan be suitably designed, becanse with positive drive there is not the same flexible action between the fan and the engine, and, with sudden acceleration and deceleration, the blades may even snap off. Positively driven fans also cannot always be driven at such high speeds, and they must, therefore, be designed to be more efficient at slower speeds.

The multi-wheel vehicle has received considerably more attention in this country since 1923, and the latest types, in their experimental and finished forms, show great promise and embody practicable features which should make a strong appeal to potential users.