Vacuum Trailer Brake with Air or Suction Control

Page 36

If you've noticed an error in this article please click here to report it so we can fix it.

A Résumé of Patent Specifications that Have Recently Been Published

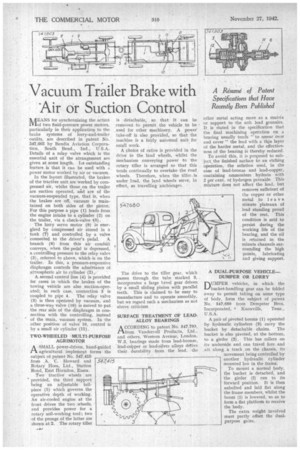

A/FANS for synchronizing the action iVlof two fluid-pressure power motors, particularly in their application to the brake systems of lorry-and-trailer outfits, are described in patent No. 547,603 by Bendix Aviation Corporation, South Bend., Ind., U S.A. Details of a relay valve which is the essential unit of the arrangement are given at some length. Rs outstanding feature is that it can be used with 3, power motor worked by air or vacuum.

In the layout illustrated, the brakes of the tractive unit are worked by compressed air, whilst those on the trailer are suction operated, and are of the vacuum-suspended type, that is, when the brakes are off, vacuum is maintained on both sides of the piston. For this purpose a pipe (1) leads from the engine intake to a cylinder (2) on the trailer, via a check-valve iS) The lorry servo motor (9) is energized by compressed air stored in a tank (7) and controlled by a valve connected to the driver's pedal. A branch (6) from this air conduit conveys, when the pedal is depressed, a controlling pressure to the relay valve (3), referred to above, which is on the trailer. In this, a pressure-responsive diaphragm controls the admittance of atemspheric air to cylinder (2), " A. second control line (4) is provided for cases in Which the brakes of the towing vehicle are also suction-operated; in such case, connection 5 is coupled to pipe 4. The relay valve (3) is then operated by vacuum, and a three-way valve (10) is moved to put the rear side of the diaphragm in connection with the controlling, instead of the main, vacuum system. In the other position of valve 10, control is by a small air cylinder (11).

TWO-WHEELED MULTI-PURPOSE AGRIMOTOR

Two tractive wheels are 1 provided, the third support being an adjustable tailpiece (1) which governs the operative depth of working. An air-cooled engine at the front drives the two wheels, and provides power for a rotary soil-working tool ; two of the prongs of the latter are shown at 2. The rotary tiller is detachable, so that it can be removed to permit the vehicle to be used for other machinery. A powertake-off is also provided, so that the machine is a fairly universal unit for small work.

A choice of ratios is provided in the drive to the land wheels, whilst the mechanism conveying power to the rotary tiller is arranged so that this tends continually to overtake the road. wheels. Therefore, when the tiller is under toad, the land wheels serve, in effect, as travelling anchorages.

The drive to the tiller gear, which passes through the tube marked 3, incorporates a large bevel gear driven by a small sliding pinion with parallel teeth. This is claimed to be easy to manufacture and to operate smoothly, but we regard such a mechanism as not above criticism SURFACE TREATMENT OF LEADALLOY BEARINGS

ACCORDING to patent No. 547,793, from Vandervell Products, Ltd., and others, Western Avenue, London, .W.3, bearings made from lead-bronze, lead-cdpper or lead-silver alloys &Five their durability from the lead, the

other metal acting more as a matrix or support to the soft lead granules. It is stated in the specification that the final machining operation on a bearing usually tends " to smear over and cover " the lead with a thin layer of the harder metal, and the effectiveness of the bearing is thereby reduced.

To avoid this, it is proposed to subject,the finished surface to an etching operation, the solution used, in the case of lead-bronze and lead-copper, containing ammonium hydrate with 2 per cent. of hydrogen peroxide This mixture does not affect the lead, but removes sufficient of • • the copper or other metal to leave minute plateaux of lead standing proud of the rest. This condition is said to persist during the working life of the bearing, and the oil is retained in the minute channels surrounding the high points. lubricating and giving support.

A DUAL-PURPOSE VEHICLE— DUMPER OR LORRY DtiMPER vehicles, in which the bucket-handling gear can be folded away to permit taking on some type of body, form the subject of patent No. 547,680 from Dempster Bros.

Incorporated, t Knoxville, Tenn., A pair of pivoted booms (1) operated by hydraulic cylinders (3) carry the bucket by detachable chains. The bucket is also pivoted, at the bottom, to a girder (2). This has rollers on its underside and can travel fore and aft alca g a track on the chassis, its movement being controlled by another hydraulic cylinder mounted low in the frame.

To mount a normal body, the bucket is detached, and the girder (2) run to its forward position. It is then unbolted and laid flat along the frame members, whilst the boom (1) is lowered, so as to form a fiat platform to receive the body.

The extra weight involved must partly offset the dualpurpose gains.