The Purchase Department.

Page 18

If you've noticed an error in this article please click here to report it so we can fix it.

Where to Buy your Supplies.

You Can Get It At .

" Wigan " (West Kilburn).—W. Tupholme and Sons, Ltd. Bridge Street, Sheffield, is the maker of the petrol-storage safes for which you inquire.

" H.H." (Lancs.).—The portable shop crane you require can be obtained from Alldayo and Onions Pneumatic Engineering Co., Ltd., Birmingham.

" M.A.S." (Finsbury).—You can obtain the expanding ferrule you mention from Barron Expanding Ferrule Co., Ltd., 27, Braemar Road, South Tottenham, London, N.

" P.C." (Ilkeston).---It is possible that the castings were made by Mattersons, of Coventry. We cannot give you a closer address, but we trust this information will suffice for you at the present time.

" Engineer " (South London).—We described the blow-lamp, you ask for in your letter, in our issue for the 6th May. It can be obtained from Brown Bros., Ltd., Great Eastern Street, London, E.G.

Terry Booklet.

Herbert Terry and Sons, Ltd., the spring and presswork specialists, has issued a small booklet, which describes fully many of the various products of this concern. Line illustrations are included with the text matter. A copy can be obtained on application to the works of the company at Redditch.

Boilerine Radiator Tablets.

Boilerine, Ltd., The Laboratories, 885a to 897, Old Kent Road, London, SE., has sent to us a list of the opinions of several of the users of 13oilerine tablets after many months use. These tablets, as some readers will be aware, prove very effective in the removal of all deposit from the radiator tubes.

Ifew Departure Ball Bearings.

The aim of modern engineering practice in designing, building and operating machinery of all kinds is to minimize friction in all rotating parts, thereby conrevving energy and securing economy of operation and ow maintenance cost. The fact has been firmly estaWished that of all types of anti-friction journal bearings the ball bearing is undoubtedly the most efficient.

The New Departure line of ball bearings consists of the following three types :—Double row or combined radial and thrust bearing, having two rows of balls, rxid sustaining loads from any angle. Single row or strictly radial bearing, having one row of balls. and taking only a slight thrust. Radax type, taking radial loads and thrust in one direction. This bearing is constructed on the eame. general principles as the double row, except that it has one row of bails instead" of two, and therefore carries the one direction thrust1 only.

The works of the New Departure Manufacturing Co., in America„ is one of the oldest and certainly one of the largest in that country. Modern methods are employed in the production ot these bearings, and only skilled workmanship is employed.

In a catalogue we have recently received from the sole British agents, Brown Bros., Ltd, Great Eastern Street, London, E.C., the New Departure ball bear ings are fully 'Cleseribed. Many pages are devoted to • descriptions of each type of bearing, their application A54 fqr specific purposes, their proper mounting, the care with which they, are manufactured ; the booklet contains useful engineering data and detailed descriptions of sizes in both the metric and the inch systems. It is printed in clear type and contains many excellent illustrations. Interested readers should apply to the company for a copy, The Automatic Gear Cutter Used as a Milling Machine.

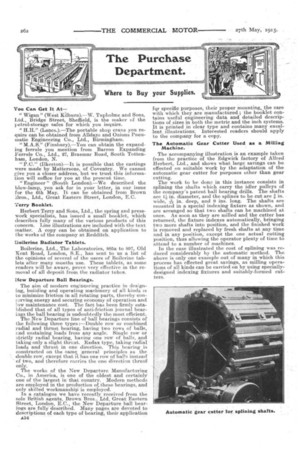

The accompanying illustration is an example taken from the practice of the Edgwick factory of Alfred Herbert, Ltd., and shows what large savings can be effected on suitable work by the adaptation of the automatic gear cutter for purposes other than gear cutting.

The work to be done in this instance consists in splining the shafts which carry the idler pulleys of the company's patent ball bearing drills. The shafts are 11in. diameter, and the splines to be cut are g in. • wide, Tar, in. deep, and 9 ins. long. The shafts are mounted in a special indexing fixture as shown, and are arranged so that two shafts can be machined at once. As soon as they are milled and the cutter has returned, the fixture indexes automatically, bringing two more shafts into position, and the finished work is removed. and replaced by fresh shafts at any time and in any position, except the one actual cutting position, thus allowing the operator plenty of time to attend to a number of machines.

In the case illustrated the cost of splining was reduced considerably by the automatic method. The above is only one example out of many in which this process has effected great savings, as milling operations of all kinds can be carried on by using speciallydesigned indexing fixtures and suitably-formed cutters.