Boilers for Steam Wagons and Tractors.

Page 2

Page 3

If you've noticed an error in this article please click here to report it so we can fix it.

Particularly About Steam Generators of the Locomotive Type.

The problem as to which is the most-suitable type of generator for a steam wagon—the locomotive type with horizontal fire-tubes, or the vertical type fitted with either smoke-tubes or water-tubes—has long been debated, and, although there are strong indications that the locomotive type (which has, all along, been used by tractor builders), is winning favour with many steam-wagon builders, greatly-improved examples of the vertical type are still retained, by, among other makers. Alley and MacLellan, Ltd., Leyland Motors, Ltd., and Robey and Co., Ltd. ; these constructors and many users of their nmehines express complete satisfaction with their types of boiler. Mr. Edwin Foden and Mr. J. H. Mann—two of our oldest manufacturers of steam wagons and carts—will at once say that there never was such a problem as that to which we have referred, because the locomotive type of boiler. which type they both use, is one that 50 years of road work, on traction engines and road locomotives, has left indisputably the best for heavy self-propelled vehicles; support would appear to be given to their contention by the fact that, although, originally, advocates for one or other of the vertical types, locomotive boilers were subsequently fitted to their wagons by Sidney Straker and Squire, Ltd., and John I. Thornycroft and Co., Ltd.

In view of its increasing popularity, we now purpose to review some points in the design of the locomotive type of boiler; we shall, also, draw attention to some of the difficulties, and the measures taken to secure increased efficiency and longer life, which have been experienced by various makers. The designs of a selected few vertical boilers will be discussed, in a subsequent section of the present article.

In the first place, however, we must acknowledge that, whilst much of our information is based upon letters received from various makers whose products are mentioned, a large amount of data has been taken from a most comprehensive paper on "improvements in Locomotive Boilers," which was prepared by Mr. Henry Fowler, M_I,Mech.E., the Chief Mechanical Engineer of the Midland Railway Co., in collaboration with Mr.

Archbutt, a chemist in the service of the. same company, for presentation at the eighth International Railway Congress, at Berne. Mr. Fowler, of course, deals particularly with boilers of large size, such as are used on modern locomotives, but much of the information that he has gleaned from the engineers of 25 different railway companies, in Great Britain and the Colonies, is of particular interest and value both to makers and users of steam wagons and tractors.

High Working Pressures.

The advantages attending the employment of highpressure steam are becoming snore and more realized, and numbers of manufacturers now build boilers for working pressures up to 220 or 225 lb. per sq. in. These higher pressures, as might he anticipated, tend to accentuate hailer troubles, and to render more imperative the use of the best water procurable and the selection and disposition of the tubes and longitudinal stays in a manner that will not cause excessive distortion of the tube-plates. Some builders have found that the troubles associated with such high pressures have not been compensated by the advantages gained, and have, in consequence, returned to a lower maximum.

The increase of pressure, and the harder work to which modern boilers are subjected, has caused more attention to be paid to the arrangement and spacing of the tubes and stays, with a view to the obtaining of greater flexibility at the corners of the tube-plate flange, where cracking—when it does occur—usually takes place.

Tubes and Their Spacing in the Tube-plates.

The employment of steel for the tubes in steam-wagon and tractor boilers is now almost universal, and its recent adoption by many railway companies has to be recorded; a still-larger number of railway engineers remains faithful to the use of brass tubes, in spite of the high prices for copper which now obtain. There are many advantages claimed for steel tubes, as compared with those made of brass, and amongst them are the following: they keep the fire-box tube-plate a better shape; they prevent leakage in long tubes; they may easily and safely be expanded into the tube-plates; the ends may be beaded. without fear of splitting ; and, unlike brass tubes, they are not likely to break off, inside the fire-box tube-plate. when high pressures exist within the boiler. There is, too, less corrosion resulting from galvanic action. Against these advantages. there nmst be set the fact that the

heat-conducting power of steel is much lower than that of copper or brass.

With regard to the spacing of tubes in the tube-plate, the Midland, the Lancashire and Yorkshire and the Southern Mahratta Railway Companies pitch the tubes

wider apart near the flange, and the Great Central Railway Co. makes a rule of never allowing any tube to be fitted within 11 in. of the flange. Another method which is adopted, as a means of decreasing the tendency to crack at the corners, is to swage down the ends of the tubes in the outside rows to I in. lees in diameter than the remaining portions of the tube. This method is in use on the London and North Western Railway. Given certain conditions of working, it seexns probable that there is seine minimum width of " bridge," or width of tube-plate metal remaining between adjacent tubes, below which it is inadvisable to go, if serious trouble from cracking between the tube-holes is to be avoided. This has been found to be the case in railway practice, and a tube-plate which will give trouble with an 11-16-in. " bridge" may stand up well if the " bridge " be increased to in. There seems to be a tendency to inTease the space between the tubes, in order that the possibility of the accumulation of dirt may be minimized, and so that washing-out can he more thorough. By the adoption of wider spacing, there is a loss of heating surface, but this objection may be offset by the more-satisiaetory working conditions.

Fireboxes.

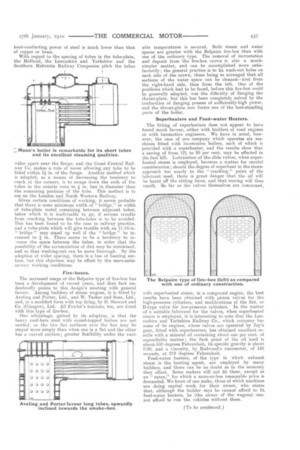

The increased usage of the Belpaire type of fire-box has been a development of recent years, and that fact undoubtedly points to this design's meeting with general favour. Among builders of steam wagons, it is fitted by Aveling and Porter, Ltd., and W. Tasker and Sons, Ltd., and, in a modified form with top firing, by D. Stewart and Co. (Glasgow), Ltd. All Fowler's tractors, too, are fitted with this type of fire-box. One advantage, gained by its adoption, is that the heavy roof-bars used with round-topped boilers are not needed, as the two flat surfaces over the box may be stayed more simply than when one is a fiat and the other has a curved surface; greater flexibility under the vari able temperatures is secured. Both steam and water spaces are greater with the Belpaire fire-box than with one of the ordinary type. The removal of incrustation and deposit from the fire-box crown is also a muchsimpler matter, and can be accomplished more satisfactorily; the general practice is to fix wash-out holes on each side of the crown, these being so arranged that all sections of the water space can be cleaned—first from the right-hand side, then from the left. One of the problems which had to be faced, before this fire-box could be generally adapted, was the difficulty of flanging the throat-plate, but this has been completely solved by the troductiion of flanging presses of sufficiently-high power, and the throat-plate now forms one of the best-standing parts of the boiler.

Superheaters and Feed-water Heaters.

The fitting of superheaters does not appear to have found much favour, either with builders of road engines or with locomotive engineers. We have in mind, however, the case of one company which operates six machines fitted with locomotive boilers, each of which is provided with a superheater, and the results show that a saving of from 12!J to 20 per cent. may be effected in the fuel bill. Lubrication of the slide valves, when superheated steam is employed, becomes a matter for careful consideration; should the degree of superheat in the steam approach too nearly to the cracking" point of the lubricant used, there is great danger that the oil will be burnt off the sliding faces, and that scoring will then result. So far as the ■ alves themselves are concerned, with superheated steam, in a compound engine, the best results have been obtained with piston valves for the high-pressure cylinders, and modifications of the flat, or D-type valve for low-pressure cylinders. 1.11 the matter of a suitable lubricant for the valves, when superheated steam is employed, it is interesting to note that. the Lancashire and Yorkshire Railway Co., which company has some of its engines, whose valves are operated by Joy's gear, fitted with superheaters, has obtained excellent results with a mineral oil containing about one per cent. of saponifiable matter; the flash point of the oil used is about 550 degrees Fahrenheit, its specific gravity is about 0.90, and a viscosity, by Redwood's viscometer, of 195 seconds, at 212 degrees Fahrenheit.

Feed-water heaters, of the type in which exhaust steam is the heating agent, are employed by many builders, and there can be no doubt as to the economy they effect. Some makers will not fit them, except as an "extra," for which a more-or-less reasonable price is demanded. We know of one make, three of which machines are doing capital work for their owner, who states that, although the builder says he cannot afford to fit feed-water heaters, he (the owner of the wagons) cannot afford to run the vehicles without them.