The Stirling could be a winner

Page 52

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

WHAT A PITY Bill Lear's steam engine project has had to be abandoned! Or so it must seem to the many who had thought the external-combusion engine could make a come-back if enough money were spent on it. And, as mentioned in Technitopics of June 27 1969, Bill Lear invested HOm in the venture.

During the past eight months, the authorities in America and this country have-been taking a more serious view of the oxides of nitrogen that can be produced by diesel engines as a potentially dangerous pollutant of the atmosphere. It is generally considered that the existing Federal ruling in America that the carbon monoxide content of an exhaust gas shall not exceed 1.5 per cent will be changed to a lower limit in due course and that other countries will eventually follow America in their legislation covering emissions. And the Reith lectures of Professor Fraser Darling on the BBC radio have made the UK general public even more pollution conscious than they were.

1816 patent

The fact that people had been playing around with the Stirling engine even before it was patented by Robert Stirling in 1816 is neither here nor there as an indication of its future. The principle of the jet engine has an equally long history and Jumbo or no Jumbo we couldn't do without it today. And this is not just facetious talk. If the internal combustion engine falls by the wayside because of anti-pollution laws and the efficient steam engine remains a pipe dream, the gas turbine and the Stirling engines could corner the entire markets.

It is possible to build a small single-cylinder Stirling having an efficiency that is very nearly as good as that of a diesel (in due course it may be better) and that will operate almost indefinitely on anything that can be ignited to produce heat. A close look at the principles and record of the Stirling has convinced me that it will win a place in the market. This will apply even if some means are found to purify the exhausts of internalcombustion engines economically and the promise of the gas turbine is fully realized. Carbon monoxide emission of the Stirling is only about 0.01 per cent, hydro-carbons in the exhaust are negligible and the emission of oxides of nitrogen is also very low.

I attended a demonstration of a Stirling single-cylinder unit at Stretford Technical College, Manchester, in April, 1968. For all the fuss and noise it made it could have been an electric motor, and with a flick of a switch it was converted into a refrigerator.

M. R. A. J. van Witteveen of Philips research laboratory, Eindhoven, . Holland, was there to explain its workings; it is significant that the performance of a 200 bhp road-vehicle version of the unit ,approximates to that of an efficient diesel. This unit operates at 1,400 rpm while a later prototype of a smaller Stirling engine has a power output of 40 bhp at 2,500 rpm, the maximum /mean efficiencies of both units being around 42/35 per cent. Torque output is remarkably uniform because variation of torque with changes of crank angle are very small, and may be compared with variations produced by a conventional piston engine having four times the number of cylinders.

The crunch The crunch comes in trying to describe the finer points of the Stirling principle and operation. Mechanically it was extremely complicated because no one had thought up the rhombic drive to simplify linking two pistons together to provide the very peculiar differential action that the cycle requires.

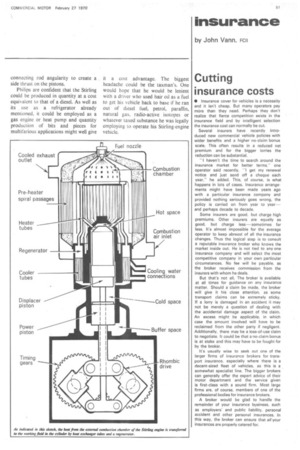

The cycle is completed in two strokes of the piston (in one revolution of the two crankshafts) and the working gas (hydrogen or helium) is pumped from the cold space between the pistons and the hot space above the upper displacer piston where it picks up heat and expands adiabatically. The gas in the cold space is cooled by a heat exchanger connected to a conventional radiator during compression to reduce the pressure (compression is virtually isothermal) and is later reheated by a regenerator and by heater tubes in the combustion chamber which is located above the cylinder. Heating is continuous, and on the second stroke the gas expands through the heater tubes and regenerator and the latter extracts heat from the gas on its way to the cold space. Gas pressure in the cold space is converted into mechanical energy in the normal way by creating a force on the pistons.

Pre-heating

If fuel is burnt in an external combusion chamber, pre-heating the intake air increases thermal efficiency and it is notable that modern types of road-vehicle gas turbine feature a regenerative pre-heater.

The intake air of the Stirling engine is circulated round a spiral type of pre-heater that is heated by exhaust gas and a large proportion of the heat of the gas is removed before it is discharged. The exhaust gas is therefore relatively cool, whereas the exhaust of a conventional piston engine removes more heat than the radiator system. The radiator has to cope with about 2+ times the amount of heat dissipated by the cooling system of a typical diesel-engine which could be an advantage if a lot of heat were required for air-conditioning purposes.

Although the maximum working pressure may be as much as 2,000 p.s.i. pressure variations are only about 2 to 1 and the rate of pressure rise is therefore very small. The heat produced by the burner can be increased to any amount dependent only on the physical strength of the engine to accommodate the pressures produced, and no extra mechanical complications (such as turbocharging) are necessary to. obtain a high output. Output is controlled by varying the gas pressure.

The rhombic drive gives complete mechanical balance and there is no connecting rod angularity to create a side thrust on the pistons.

Philips are confident that the Stirling could be produced in quantity at a cost equivaient to that of a diesel. As well as its use as a refrigerator already mentioned, it could be employed as a gas engine or heat pump and quantity production of bits and pieces for multifarious applications might well give it a cost advantage. The biggest headache could be the taxman's. One would hope that he would be lenient with a driver who used hair oil as a fuel to get his vehicle back to base if he ran out of diesel fuel, petrol, paraffin, natural gas. radio-active isotopes or whatever taxed substance he was legally employing to operate his Stirling-engine vehicle.