Patents Completed.

Page 20

If you've noticed an error in this article please click here to report it so we can fix it.

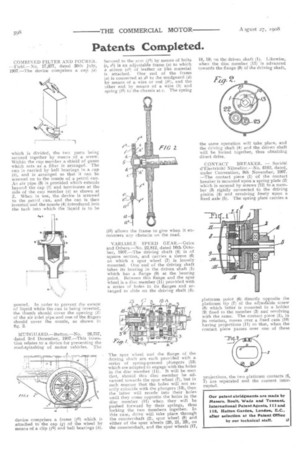

COMBINED FILTER AND POURER. —Field.—No. 17,377, dated 30th July, 1907,—The device comprises a cup (a) which is divided, the two parts being secured together by means of a screw. Within the cup member a shield of gauze which acts as a filter is arranged. The cup is carried by ball bearings in a cap ,(b), and is arranged so that it can be screwed on to the nozzle of a petrol can. An air pipe (3) is provided which extends beyond the cap (b) and terminates at the side of the cup member (a) as shown at Z. When in use, the device is screwed to the petrol can, and the can is then inverted and the nozzle (4) introduced into the tank into which the liquid is to be

poured. In order to prevent the escape of liquid while the can is being inverted, the thumb should cover the opening (7) of the air inlet pipe and one of the fingers should cover the nozzle, as shown in fig. 2.

MUDGUARD.—Button.—No. 26,757, dated 3rd December, 1907.—This invention relates to a device for preventing the mud-splashing of motor vehicles. The

device comprises a frame (f2) which is attached to the cap (g) of the wheel by means of a clip (/3) and ball bearings (h). Secured to the arm (f2) by means of bolts (e, el) is an adjustable frame (a) to which a screen (02) of leather or like material is attached. One end of the frame (a) is connected at dl to the mudguard (d) by means of a wire or rod (bl), and the other end by means of a wire (8) and spring (62) to the chassis at c. The spring

VARIABLE SPEED GEAR.—Grice and Others.—No. 22,812, dated 16th October, 1907.—The driving shaft (4) is of square section, and carries a sleeve (6) on which a spur wheel (7) is loosely mounted. One end of the driving shaft takes its bearing in the driven shaft (1) which has a flange .(9) at the bearing point. Between this flange and the spur wheel is a disc member (11) provided with a series of holes in its flanges and arranged to slide on the driving shaft (4).

The spur wheel and the flange of the driving shaft are each provided with a series of spring-pressed plungers (13) which are adapted to engage with the holes in the disc member (11). It will be seen that, should this disc member be advanced towards the spur wheel (7), but in such manner that the holes will not exactly coincide with the plungers (13), then the latter will recede into their holes until they come opposite the holes in the disc member (11) when they will be pushed forward by their springs, thus locking the two members together. In this case, drive will take place through the countershaft (2), spur wheel (8) and either of the spur wheels (20, 21, 23), on the countershaft, and the spur wheels (17, 18, 19) on the driven shaft (1). Likewise, when the disc member (11) is advanced towards the flange (9) of the driving shaft, the same operation will take place, and the driving shaft (4) and the driven shaft will be locked together, thus obtaining direct drive.

CONTACT BREAKER. — Societe d'Electricite'. Nilm el ior.—No. 6162, dated, under Convention, 9th November, 1907. —The contact piece (1) of the contact breaker is mounted upon a spring plate (2) which is secured by screws (12) to a member (3) rigidly connected to the driving pinion (4) and revolving freely upon a fixed axle (5). The spring plate carries a platinum point (6) direc ly oeposite the platinum tip (7) of the adjustable screw (8) which latter is mounted in a holder (91 fixed to the member (3) and revolving with the same. The contact piece (1), in its rotation, moves over a fixed cam (10) having projections (11) so that, when the contact piece passes over one of these projections, the two platinum contacts (6, 7) are separated and the current interrupted.