SOME DEFECTS OF EARLY DESIGN.

Page 10

Page 11

If you've noticed an error in this article please click here to report it so we can fix it.

How the Defects were Gradually Discovered and Eliminated—IL!.

TUE GEARBOX is perhaps, that part of the motor vehicle which has shown least advance in 'design from the earliest days, since it is even now so far froth perfect that it is a matter for wonder that some more mechanical contrivance than the clash-type, step-up gearbox has not before now been brought into general use. The inherent defect in all such arrangements is, of course, the fact that the range of speed froth high to low is limited to a small number of definite steps and, until these steps can be eliminated and a gradual increase of speed ratio made possible, we shall not have advanced very far frOm the productions of tne dark ages of motoring.

.Setting aside the fact that most early designs provided but three speeds, whereas four are now rightly oonsidered the minimum, we shall observe that progress his been made in the direction of a smaller and lighter unit, more accurately cut gears, which are therefore less noisy in operation, and in the use of ball bearings which have not only given increased efficiency butt if of ample size, prevent one source of noisy running very common in early ears, viz., slack shaft bearings. The excessively large gearboxes often fitted at one time were largely due to the obsolete "straight through" type of change speed gear, which employod only one set of sliding wheels moving from one end of the box to the other in passing from bottom to top speed through the intermediate gear position. This arrangement, as will be seen at a glance in the annexed sketch, iiecessitated longer shafts than the more modern design employiug two sliding wheels, and, in turn, gave, rise to lack of rigidity when transfoitting the drive unless the shafts were made of extremely heavy section.

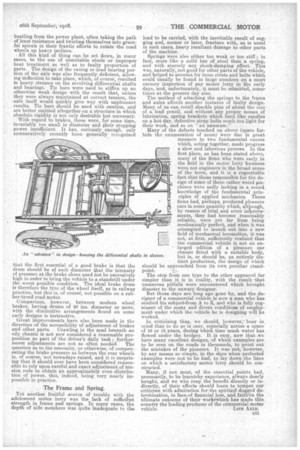

There was also, of course, the obvious difficulty in driving of not having a neutral position from which any gear could be selected at will without any other pair of gears being brought into mesh en route, as well as the possibility of overrunning the intermediate gears, which cannot occur with the. modern selective gate system. Other minor defects, due to lack of experience in design or manufacture, were leaky joints and bearings, which allowed escape of oil, this being also sometimes due to lack of an air vent to prevent internal pressure due to the heat generated by friction in running. Owing to the prevalence of the chaindrive most early gearboxes were incorporated w,ith the differential gear, this B30 being housed in the same easing, or an extension of it, and the differential shafts extended on either side to carry the chain Sprockets outside the frame. In this particular arrangement, a very serious fundamental error was prevalent for some time, which caused a considerable amount of trouble to some makers and not efew users. This error consisted in carrying the outer ends of the differential shafts on separate bearing brackets, bolted to the side members, which were supposed to be, and no doubt were, accurately aligned on the chassis when built, but which invariably became very much out of truth after a, short tithe on the road, with the result that all sorts of uncanny tbings used to happen in the way of broken differential shafts, tight bearings, etc. After a great deal or this kind of thing, designers began to think hard, and, rightly, came to the belated conclusion that such form of construction, was essentially. unmechanical and, therefore, Wrong in principle. The system then began to develop of housing the differential shafts in sleeveli rigidly fixed to the gearbox or differential casing, these sleeves themselves carrying the outer bearing and also the weight of the gearbox at the point of attachment to the side members. Even when matters had reached this stage, troubles were not over, as gearboxes would occasionally collapse and fall out on the road, due to insufficient strength in the design of the ease and sleeves • castiron or aluminium, particularly the former, notoriously dangerous materials unless used with great discretion.

Transmission and Rear Axle.

It is open to question whether the chain drive system can be rightly called a defect in design. In the writer's opinion, it is so, and is, consequently, slowly passing out of use. in favour of the more efficient and quieter live axle. In the early days many manufacturers were genuinely afraid of the live axle and, we must admit, with some show a reason in view o the amount of trouble which it brought tC, f some unfortunate pioneers, not through any fault of its own, so to speak. The differential gear and drive shafts were prone to cry " kameradl " after a. very small amount of hustling from the power plant, often taking the path of least resistance and twisting themselves into graceful spirals in their frantic efforts to rotate the road wheels up heavy inclines.

All this kind of thing can be set down, in many cases, to the use of unsuitable steels or improper heat treatment as well as to faulty proportion of parts. The design of the casing or load bearing portion of the axle was also frequently deficient, allowing deflection to take place, which, of course, resulted in heavy stresses on the revolving differential shafts and bearings. Tie bars were used to stiffen up an otherwise weak design with the result that, unless they were always maintained at correct tension, the axle itself would quickly give way with unpleasant results. Tie bars should be used with caution, and are better omitted altogether on a structure in which absolute rigidity is not only desirable but necessary.

With regard to brakes, these were, for some time, invariably too small in diameter and their stopping power insufficient. It has, curiously enough, only comparatively recently been generally recognized

that the first essential of a good brake is that the drum should be of such diameter that the intensity of pressure at the brake shoes need not be excessively high in order to bring the vehicle to a standstill under the worst possible condition. The ideal brake drum is therefore the tyre of the wheel itself, as in railway practice, but this is, of course, not possible on a rubber-tyred road motor.

Comparison, however, between modern wheel brakes, having drums of 20 ins, diameter or more, with the diminutive arrangements found on some early designs is instructive.

Great improvements have also been made in the direction of the accessibility of adjustment of brakes and other parts. Crawling in the mud beneath an oily chassis is not now considered a reasonable proposition as part of the driver's daily task • further,more adjustments adjustments are not so often needed. The question as to the necessity, or otherwise, of compensating-the brake pressure as between the rear wheels is, of course, not nowadays raised, and it is surprising that it should ever have been considered reasonable to rely upon careful and exact adjustment of tension rods to obtain an approximately even distribution of power, this, indeed, being very nearly impossible in practice.

The Frame and Spring.

Yet another fruitful source of trouble with the adolescent motor lorry was the lack of sufficitnt strength in frame and springs. In many cases, the depth of side members was quite inadequate to the

load to be carried, with the inevitable result of sagging and, sooner or later, fracture with, as is usual in such cases, heavy resultant damage to other parts of the machine.

Springs were also either too weak or too stiff ; in fact, more like a solid bar of steel than a spring, and with scarcely any shock-damping effect. This was, naturally, not good for other parts of the vehicle, and helped to account for loose rivets and bolts which could usually be found in large numbers on a most cursory inspection of any motor lorry in the early days, and, unfortunately, it must be admitted, sometimes at the present day also. The method of attaching the springs to the frame and axles affords another instance of faulty design. Many of us can recall shackle pins of about the size of a lead pencil, and without any proper means of lubrication, spring brackets which bent like candles on a hot day, defective strap bolts much too light for their work, and so on "ad nauseam."

Many of the defects touched on above (space forbids the enumeration of more) were due in great measure to two fundamental causes which, acting together, made progress a slow and laborious process. In the first place, as has been stated above, many of the firms who were early in the field in the motor lorry business were not engineers in the broad sense of the term, and it is a regrettable fact that those responsible for the design of some of these rather weird piachines were sadly lacking in a sound knowledge of the fundamental principles of applied mechanics. These firms had, perhaps, produced pleasure cars in some quantity which, although, by reason of trial and error iniprovemeats, they had become reasonably reliable, were yet far from being mechanically perfect, and when it was attempted to launch out into a new, field of mechanical locomotion, it was not, at first, sufficiently realized that i the commercial vehicle s not an enlarged edition of a pleasure car chassis fitted with a suitable body, but is, or should be, an entirely distinct production, the design of which should be approached from its own peculiar standpoint.

The step from one type to the other appeared far simpler than it is in reality, with the result that numerous pitfalls were encountered which brought disaster to the unwary designer.

But those days are long ago gone by, and the designer of a commercial vehicle is now a man who has studied his subjeet‘from A to Z, and who is fully cognizant of the many and divers conditione of employment under which the vehicle he is designing will be worked.

In criticising thus, we should, however,bear in mind that to do so is easy, espe,cially across a space of 10 or 16 years, during which time much water has flowed under the bridges. It is easy, now that we have many excellent designs, of which examples are to be seen on the roads in thousands, to point out the mistakes of the pioneers. It was not, however, by any means so simple, in the days when perfected examples were not to be had, to lay down the lines on which a satisfactory motor lorry should be constructed.

Many, if not most, of the essential points had, necessarily, to be learnt.by experience, always dearly bought, and we who reap the benefit directly or indirectly, of their efforts should learn to temper our criticism with admiration for'the spiritof dogged deterrnination, in face.of financial loss, and faithiin the ultimate outcome of their worktwhich has made this country the leading producer of the commercial motor vehicle, LrvE Axen. in sleeves.