Check those oil seals

Page 46

If you've noticed an error in this article please click here to report it so we can fix it.

AT SEVERAL different places on a vehicle's engine and transmission system a situation arises where oil must be prevented from passing along a revolving shaft and escaping either to make a nasty mess or to find its way into another compartment where it can do damage.

A classical example of the latter case is found on an engine's rear bearing. Oil is pumped into the bearing under considerable pressure to lubricate it and this oil must be prevented from leaking out from the rear end of the bearing into the clutch housing and perhaps on the clutch itself.

If this does happen the clutch cannot function properly; it will probably "slip" or alternatively become sticky and fail to ''free'' when the clutch pedal is pressed causing a grating noise when the driver tries to engage a gear.

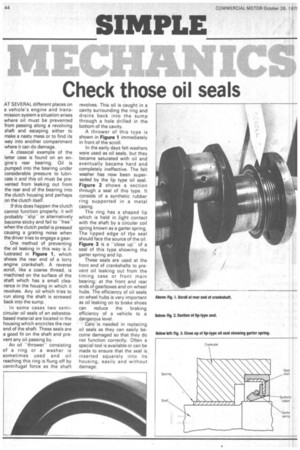

One method of preventing the oil leaking in this way is illustrated in Figure 1, which shows the rear end of a lorry :engine crankshaft. A reverse ,scroll, like a coarse thread, is -machined on the surface of the shaft which has a small clearance in the housing in which it revolves. Any oil which tries to run along the shaft is screwed back into the sump.

In some cases two semicircular oil seals of an asbestosbased material are located in the housing which encircles the rear end of the shaft. These seals are a good fit on the shaft and prevent any oil passing by.

An oil "thrower" consisting of a ring or a washer is sometimes used and oil reaching this ring is flung off by centrifugal force as the shaft revolves. This oil is caught in a cavity surrounding the ring and drains back into the sump through a hole drilled in the bottom of the cavity.

A thrower of this type is shown in Figure 1 immediately in front of the scroll.

In the early days felt washers were used as oil seals, but they became saturated with oil and eventually became hard and completely ineffective. The felt washer has now been superseded by the lip type oil seal.

Figure 2 shows a section through a seal of this type. It consists of a synthetic rubber ring supported in a metal casing.

The ring has a shaped lip which is held in light contact with the shaft by a circular coil spring known as a garter spring. The lipped edge of tbe seal

should face the source of the oil. Figure 3 is a "close upof a seal of this type showing the garter spring and lip.

These seals are used at the front end of crankshafts to pre vent oil leaking out from the timing case or front main bearing; at the front and rear ends of gearboxes and on wheel hubs. The efficiency of oil seals on wheel hubs is very important as oil leaking on to brake shoes can reduce the braking efficiency of a vehicle to a dangerous level.

Care is needed in replacing oil seals as they can easily be come damaged so that they do not function correctly. Often a special tool is available or can be made to ensure that the seal is , inserted squarely into its housing, easily and without damage.