BUSES and bicy

Page 50

Page 51

Page 52

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

By John F. Moon, A.M.I.R.T.E.

IT is significant that Utrecht, which is the central city of Holland in more ways than one, should rely on British-built buses and components to provide its inhabitants and numerous visitors with a public transport service worthyof this famous town. The use of British • vehicles is a growing trend throughout the Netherlands and proves that the United Kingdom can offer the best vehicle for the best price, despite active competition from close neighbours such as Belgium, France,

Germany and Sweden. . , The increased sales of British vehicles in Holland are encouraging manufacturers to improve their service facilities there. Leyland Motors, Ltd., are among those who have done so by opening the fine new Ceyland. Holland depot at Aarlsrneer. The Utrecht transport undertaking has a large number of Leyland vehicles, so the opening of this new depot was not without its importance to their engineers.

Utrecht, which lies near the geographical centre of the Netherlands, is a city of some 240,000 inhabitants and is one of the most important industrial and commercial areas in the country. Shipping plays a prominent part in its livelihood, as the city lies on the.Amsterdam-Rhine ' Canal, which was opened in 1952. It is also the centre of the Netherlands Railways and the site of an important annual trade fair. The municipality covers an area of 200 sq. miles, but a large expansion programme is planned and by 1970 the population is expected to have risen by 70,000, with a corresponding increase in area.

Despite the population and influx of visitors, however, a large fleet of buses is not considered necessary. This is not because of cars, for few people travel into the city . by car because of parking problems. The principal reason is the bicycle—the chief competitor that any Dutch public transport undertaking has to face. Bicycles, for instance, make all routes unremunerative during the summer, whereas they are all paying propositions during the winter. Nevertheless, the lJtrecht Municipal Power and Transport Department—G.E.V.U.--continues to provide efficient and frequent bus 'services on all routes in the city throughout the year. Similarly, maximum comfort and safety at the lowest possible cost to passengers are ensured by the use of first-class vehicles and drivers, and a comprehensive system of traffic control.

A remarkable achievement is that the flat-rate fare charged on all buses has been increased by only 5 cents (l Id.) since 1959—a 50 per cent, increase compared with a general advance in the cost of living of 300 per cent. Were the transport department to raise fares above this figure, those people in Utrecht now without bicycles would soon buy them. • G.E.V.U. springs from the institution in 1906 of an electric tram system in Utrecht. The first.petrol-engined buses were purchased in 1925, these being De Dion Boutons, and a Bedford bus, bought in 1937, was the first British vehicle to run with the undertaking. Trams were disposed of in 1937, and the present fleet totals about 100 buses

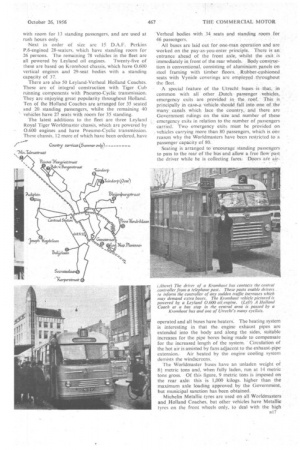

The smallest vehicles in the fleet are four American FordTear--engined transit buses which have -26 seats,

With room for 13 standing passengers. and are used at rush hours only.

• Next in order of size are 15 D.A.F. Perkins P.6-engined 28-seaters, which have standing room for 26 persons. The remaining 78 vehicles in the fleet are all powered by Leyland oil engines. Twenty-five of these are based on Krornhout chassis, which have 0.600 vertical engines arid 29-seat bodies with a standing capacity of 37.

There are also 50 Leyland-Verheul Holland Coaches. These are of integral construction with Tiger Cub running components with Prieurno-Cyclic transmission. They are enjoying great popularity throughout Holland. Ten of the Holland Coaches are arranged for 35 seated and .20 standing passengers, whilst the remaining 40 vehicles have 27 seats with room for 35 standing.

The latest additions to the fleet are three Leyland Royal Tiger Worldmaster chassis, which are powered by 0.600 engines and have Pneurno-Cyclic transmission. These chassis, 12 more of which have been ordered, have Verheul bodies with 34 seats and standing room for 46 passengers. • •

All buses are laid out for one-man operation and are worked on the pay-as-you-enter principle.. There is an entrance ahead of the front .axle, whilst the exit is immediately in front of the rear wheels: Body construction is conventional, consisting of aluniinium. panels on steel framing with timber floors. . Rubber-cushioned seats with Vynide coverings are employed throughout the fleet.

-A special feature of the Utrecht buses is that, in• common with all other Dutch passenger vehicles, emergency exits are provided in the roof. This is principally in caso...a vehicle should fall into one of the manycanals which lace the country, and there are Government rulings on the size and number of !these emergency exits in relation to the number of passengers carried. Two emergency exits Must be provided on vehicles carrying more than 80 passengers, which is one reason why the Worldmasters have been restricted to a passenger capacity of 80.

Seating is arranged to 'encourage standing passengers to pass to the'rear of the bias and allow a fret flow past the driver while he is collecting fares: DOors are air

operated and all buses have heaters. The heating system is interesting in that the. engine exhaust pipes are extended into the body and along the sides, suitable increases for the pipe bores being • made to compensate for the increased length of the system. Circulation of

the hot air is assisted by fans adjacent to the exhaust-pipe extension. • Air heated by the engine cooling system demists the windscreens.

The Worldmaster buses have an unladen weight of metric tons and, when fully laden, run at 14 metric tons gross. Of this figure, 9 metric tons is imposed on the rear axle: this is 1,000 kilogs. higher than the maximum axle loading approved by the Government, but municipal sanction has been obtained.

• Michelin Metallic tyres are used on all Worldmasters and Holland Coaches, but other vehicles have Metallic tyres on the front wheels only, to deal with the high front-axle loadings caused by the forward engine position and standing passengers who, despite the gangway arrangements, still seem to prefer to stand at the front of the bus.

There are 12 principal routes, but in the summer three additional country services are run, together with sightseeing tours within the city itself. The total route mileage is 40. The longest route is 4+ miles and the

shortest, 2+ miles. Frequencies vary between six and 11 minutes.

The narrow streets in the city centre normally carry dense traffic during the day, which means that on some routes with narrow streets the 30-ft.-long buses, such as the Holland Coaches, are the largest which may be used. There are, in fact, at present only four routes over which the 36-ft. Worldmasters are operated.

Five Stops Per Mile

There are five bus stops per mile on every route. Maximum speed is not important and all buses in the Utrecht fleet are restricted to 37 m.p.h. Relatively low axle ratios are employed and, combined with engines of high torque ratings, give the good acceleration essential for correct adherence to running schedules.

The exceptions to this rule are the 10 35-seat Holland Coaches. These are used on the summer

tours and have Eaton 16,500 two-speed axles. It

is unusual to find Eaton axles in use with fluid couplings and Pneumo-Cyclic gearboxes, but as the higher ratio is used only out of the city, ratio changes are made when the vehicles are stationary.

Last year, 25m. passengers were carried and the total mileage run was 3m. In 1954, 23m. passengers were carried and 2.8m. miles were covered, but because of the increased custom and higher fares the loss sustained by the department decreased from £42,000 in 1954 to £39,900 in 1955.

The morning peak occurs between 7.30 and 8.30 and the evening peak between 5,0 and 6.30. The high frequency of services maintained throughout the day, however, means that generally only 16 extra buses are put into service during peak periods, 67 buses being used throughout the day and 83 during rush hours.

A flat fare of 15 cents (3 +d.) applies on every route. All tickets are time-stamped by drivers when issued, because each ticket allows one change on to a different route within three-quarters of an hour of issue.

Reasonable Fare Rates

Reasonable as these fare rates may seem, greater value for money is offered in respect of cards which are issued for four journeys at 50 cents (1110 or for eight trips at a guilder (Is. 11d.). A still better bargain is the weekly ticket, which permits two journeys per day for six days at a cost of 1.25 guilders, whilst school tickets are sold for 3 guilders, each ticket being valid for a month. All employees are allowed 50 free journeys every three months.

The principal terminal point (Central Station) is used by 13 routes, including two country services. It is well laid out in bays with covered accommodation for passengers. All these bays can be observed by a controller in an elevated control post overlooking the terminal. He can telephone to any of the bays to issue al8 route and running instructions and is thus able to keep passenger traffic on the move throughout the day and send out additional buses if sudden demands should occur.

In addition, all routes have telephones along them to enable drivers to keep in touch with the controller. This system has proved to be particularly useful when large queues have formed at stops for no apparent reason and has enabled additional buses to be pressed into service.

There is only one maintenance depot and this is in the centre of Utrecht adjacent to the offices. It consists principally of the old train sheds, and the chief engineer does not pretend to be happy with the present rather dilapidated workshop and is eager to see the completion of a new garage on Canal Island, which is planned for completion by 1958.

The present workshop has space for only 17 buses, two pits being used solely for lubrication and five for routine maintenance. Some of the other pits are long ones formerly used for trams and providing room for four buses, but none is ideally suited to working on underfloor-engined vehicles.

Despite these difficulties, a rigid maintenance programme has been laid out. This can virtually be said to start with the forms which every driver has to sign. every four hours while on the road to certify that his vehicle is performing correctly. Any defect shown by these forms is immediately rectified.

Regular maintenance consists of nightly level checks, a small night staff being employed for this purpose. At 1,500-mite intervals A maintenance is carried out, this consisting of overall lubrication and detail .attentions to running components. 13_ maintenance—engine-oil and oil-filter-element changes, plus an A check—is executed at 3,000-mile intervals, or every 4,500 miles in the case of the Leyland 0.600-engined buses.

At every 9,000 miles the C routine is carried out on all

• vehicles. This consists of stages A and B, plus axle and gearbox oil changes, and attention to steering and fuel filters. D maintenance is given at 18,000 miles and comprises a full C programme, together with a change of injectors. An E overhaul takes place every 36,000 miles and consists of decarbonizing, valve grinding, and changes of fuel-injection pump, dynamo, starter and voltage-control regulator.

Engine overhauls are carried out every 72,000 miles, if necessary, but so far the Leyland 0.600 engines have covered 150,000 miles without so much as a piston-ring change, and the oil-consumption rates of these engines • are still low enough to warrant no attention being given to them.

Engines will be rebuilt in the workshops, with the exception of crankshaft regrinds. It is confidently expected that the Leyland 0,600 engines will cover at least 230,000 miles before rebuilding becomes necessary. Engines of other makes are reconditioned by the appropriate agents.

Injector nozzles are attended to in the workshops, although fuel-injection pumps are not, but all other maintenance and reconditioning are carried out by the G.E.V.U. staff.

Labour in the workshops provides certain problems, as skilled mechanics are scarce in Utrecht and many of them go to other towns to more highly paid jobs. • At present the workshop staff totals 80.. There are 250 drivers and a -high standard is preserved. New drivers, if not already bus drivers, must have driven heavy goods vehicles and they are given four weeks' concentrated training before being put in charge of a bus.

The future programme of G.E.V.U. hinges on the new garage, mainly because the present tram shed is uneconomic to operate. The new depot will at first have a capacity for 150 buses, but this will be expanded to 250, because by 1970 a fleet of 180 buses will be necessary. The general manager intends to standardize his fleet on two types of bus and whilst he would prefer to adopt Leyland chassis, he can do so only if the town council consider them economic to buy when compared with other makes. So far he has found that there is nothing better for the same price, but he is always looking for better and cheaper buses, which should be taken as a warning to British makers.

His principal requirements are good acceleration (high torque and low-ratio gearing); simple gear-change systems to reduce the driver's work; and efficient braking, In respect of transmission, the Pneumo-Cyclic arrangement meets with his approval, although he looks forward to the use of fully automatic transmissions. Current air-pressure braking systems are satisfactory and brake fade is rarely encountered. In an effort to lengthen facing life, experiments are to be conducted with exhaust brakes.

The Worldmaster vehicles were chosen because of the annual rise in the number of passengers carried. Very high capacity is proving particularly useful at peak periods and is helping to keep the size of the fleet down to reasonable limits. Although integral buses are preferred by reason of their lightness, it was considered that the Worldmaster chassis weight was sufficiently low, and weight has been saved by welding the bodywork directly to the chassis frame. Unladen weight is a primary influence on tyre wear, particularly in view of the five stops per mile along all routes. At present, for example, the front tyres on a Holland coach last for about 15,000 miles, whilst those at the rear have twice the life.