3666 lb. of Welsh Coal per Mile.

Page 4

Page 5

Page 6

If you've noticed an error in this article please click here to report it so we can fix it.

A Record of a " C.M." Trial of the New Garrett 3-ton Steamer, Conducted by a Member of the Editorial Staff.

Impressed by what appeared to be remarkable coal consumption results, which had been achieved during the first road tests of a new model 3-ton steam wagon, Garrett's of Leiston took steps immediately to secure an independent record of its performance. The first of its type, a small rubbertired relative of the better-known 5-ton steamer, it had only left the shops of Richard Garrett and Sons,

Ltd., a few days, for its road tests, when, late one evening recently, the editorial office of THE COMMERCIAL MOTOR was called up on the telephone, and a request. was made that a representative might, with as little delay as possible, carry out whatever tests were considered suitable in order definitely to establish a consumption standard for the new machine, The complete vehicle had to be painted and delivered within three or four days, so that, under these circumstances, arrangements were at once ' made to fall in with the maker's wishes.

Arrived at Leiston overnight, Mr. Stephen Garrett took personal charge of the comfort of our representative, who was informed that it was the company's wish that every possible facility should be afforded him for the effective conduct of an independently-observed trial. Mr. Frank Walker., who has charge of the testing and research departments at the Leiston works, placed himself and his staff at the entire disposal of the member of our staff.

Early on the following morning, a Friday, those who were concerned with the test, of which the programme had been settled on the previous evening, proceeded to make a detailed examination of the wagon, after the boiler had been "lighted up." In the meantime, preparations were being made for the due measuring and weighing of the fuel, water and load, which were to be used during the test. This new model is of the 3-ton load-carrying class and is designed for use on solid rubber tires, in

order to have a legal maximum speed of 12 m.p.h. The weight in running order is about 5 tons. The general arrangement is according to the over-type design, which has now become so popular with steamwagon builders. The compound engine, which is mounted over the boiler, and of which the steam jackets are in direct connection with the top of the shell, has a H.P. cylinder bore of 31 in. and a L.P. bore of 5i in. ; the stroke is 6 in. The valve motion is of the usual link type, but the use of a superheater has rendered it advisable to employ balanced piston valves. The crossheads reciprocate in large-diameter tubular guides. The usual valve arrangement for running both the cylinders on H.P. steam is provided, and special :provision is made, when the engine is so operated, to keep the two exhausts separate.

The boiler is of the kco, type, but with important Garrett characteristics. As with all this maker's other sizes of boilers, no crown stays are used, the fire-box roof being corrugated. The grate area on this 3-ton model is 2.25 sq. ft., and the total heating surface amounts to 53 sq. ft. Forty-seven

in. tubes connect the tube plates. The working steam pressure is 200 lb. per sq. in. In order to secure maximum economy of coal and water consumption, Garrett's make it aa, practice to fit both feedwater heaters and superheater coils on almost all the varying classes of steam plant which they produce. The latest steam wagon is no exception to this practice. The feed water heater is of a simple tubular

type, and is carried on the near side of the boiler. The superheater is of a new pattern and consists of return tubes located in a header, which is suspended in the smokebox immediately over the top row of boiler tubes. The steam connections, in order to include this additional equipment, are carefully arranged to secure as short a delivery as possible. The main supply is taken from the steam jacket, which, being in direct connection with the steam space of the boiler itself, is the equivalent of a steam dome— priming, we are told, is unknown on a Oarrett machine. The steam is then taken through the superheater tubes up to the main steam cheat. The H.P. cylinder is lubricated by a mechanical lubricator, whilst a displacement oiler is used on the L.P. side.

The main water tank on the standard 3-ton wagon contains 140 gallons, which, we are well satisfied, will be sufficient for 50 miles of ordinary running. A high-capacity injector and a geared feedpump, take charge of the water supply to the boiler ; a water-lifter and a suitable length of flexible suction hose are, as is usual, provided for tank replenishment. The transmission presents no unusual features ; it consists of the usual form of two-speed gear and of a long roller-chain drive to a live axle which contains the differential ar. There is a flywheel brake, and one on the back axle.

The main frame is carried right forward to the front of the boiler shell, where it terminates in .a flexible form of bracket suspension. The steering tackle is of the traction type, and the road wheels are of artillery pattern, 42 in. at the back and 32 in. in front ; the back wheels are shod with twin tires. On the vehicle which was, in this instance, submitted to test, the tires were all Polacks.

As a preliminary to the run on the road, and subsequent to detailed examination of the machine, load, fuel and water were carefully measured. The spring balance,

was, first of all, calibrated. The load consisted of 54 sacks of cement and one sack of coal, each of which was carefully weighed, and of the two people who were engaged on the test, other than the driver and his assistant. This yielded a net load of 6,910 lb., or 190 lb. in excess of three tons. The load when placed on board was carefully sheeted. The coal, which was Nixon's Navigation, but which contained a larger proportion of dust than is usual, was next carefully weighed. Two cwt. was placed in the bunker, and an additional 170 lb. was carried in reserve on the platform with the load. The water, at the commencement of the run, showed n in. in the boiler gauge and 9/ in. in the main tank

gauge. The boiler pressure was then 200 lb.

An odometer, a "Perfect Distance Recorder," was fixed to the off-side front wheel. In order to test the accuracy of this instru e t, in conjunction with the newly-tired wheel to which it was attached, five test miles were run between different milestones, after

the completion of the fuel-consumption trial. These subsequent tests revealed a net average error of 3.12 per cent. against the wagon, the record being low to that extent. The mileage record on the actual trial run was therefore inereased accordingly. All the tires were new, and at the start of the observations the odometer showed 1-16th of a mile.

After examination of the state and level of the fire, in order that, at the completion of the run, similar conditions should prevail, the order was given to start at four minutes past noon. The driver was warned to endeavour to keep his average speed about 12 m.p.h. As events turned out, this was considerably exceeded, largely on account of the absence of traffic hindrances on the way and of the satisfactory climatic conditions. The selected route was from Leiston via Yoxford and Wangford to the outskirts of Lowestoft and back, which was estimated to yield a run of about 48 miles. The roads on the whole were in first-class condition—well-kept macadam for twothirds of the way, whilst the re mainder was somewhat sandy. The surface was hard and dry, therefore, with the exception of a

stretch of about mile, where mending operations were proceeding. The route selected provided a good give-and-take run through typical East Anglian country, which is, of course, not hilly. There were no serious gradients, and at no part of the run was the use of the lov% gear necessary. On six occ-, •

both cylinders were put on H.P. for a short period, in order to keep up the speed on inclines.

A few hundred yards out, a stop of 2 min. was necessary owing to a closed level crossing. After a steady run of just over an hour's duration, a halt of J. min, was called, to oil an eccentric strap and to replenish certain lubricators. As the wagon was new, it was decided not to check the free use of lubricant. At 1.40 p.m. the wagon was carefully levelled, the tank was filled from a wayside stream near Kessingland, and the water gauge was measured. The southern tramway terminus in Lowestoft was decided upon as the turning point, and a delay of eight minutes was here allowed for lunch before starting the return journey. Firing had been done very carefully and at long intervals up to this point and was so continued for the rest of the run. At 2.22 p.m. the return journey was commenced and a non-stop run was made to Wangford, where the second supply of water was taken, and a telegram was despatched. This stop occupied 21 minutes altogether. Leiston was again reached without any un toward incident at. 1.24. An inspection of the fire and the boiler gauge rendered it advisable to make a further short trip.

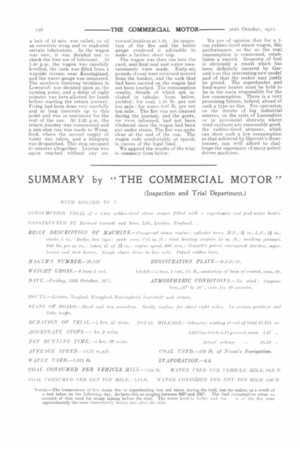

The wagon was then run into the yard, and final coal and water measurements were made. Forty-six pounds of coal were returned unused from the bunker, and the sack that had been carried on the wagon had not been touched. The consumption results, details of which are included in tabular form below, yielded : for coal, 1.18 lb. per net ton mile ; for water 8.07 lb. per net ton mile. The fire was not cleaned during the journey, and the grate, we were informed, had not been clinkered since the wagon had been put under steam. The fire was quite clear at the end of the run. The wagon rode comfortably at speeds in excess of the legal limit.

We append the results of the trial in summary form below.

We are of opinion that for a 3ton rubber-tired steam wagon, this performance, so far as the coal consumption is concerned, establishes a record. Economy of fuel is obviously a result which has been definitely ensured by Garrett'S on this interesting new model and of that the maker may justly be proud. The superheater and feed-water heater must be held to be in the main responsible for the low consumption. There is a very promising future, indeed, ahead of such a type as this. For operation on the streets of big industrial centres, on the setts of Lancashire or in provincial districts where road surfaces are reasonably good, the rubber-tired steamer, which can show such a low consumption as that achieved by Garrett's threetonner, can well afford to challenge the supremacy of many petroldriven machines.