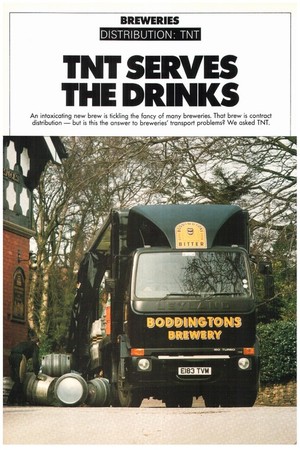

TNT SERVES THE DRINKS

Page 52

Page 53

Page 54

If you've noticed an error in this article please click here to report it so we can fix it.

An intoxicating new brew is tickling the fancy of many breweries. That brew is contract distribution — but is this the answer to breweries' transport problems? We asked TNT.

• Contrary to expectations, perhaps, TNT Brewery Distribution does not sell its service on price.

General manager David Alvarez dismisses claims by another brewery distribution contractor, National Carriers Contract Services, that brewers could save £2.30 per barrel by contracting out their distribution.

"We never ever talk on price," he says. "If ever we talked on price we would regret it sooner or later. Trying to predict the cost of a brewery's distribution is difficult: if we estimated the average cost, half the time costs would be below and half the time above that level. It's an impossible approach and very imprudent and one we would be likely to regret. We do not just save money for the breweries; we provide extra service too."

In 1961 TNT won its first distribution contract, with Tooheys, the Australian brewery that makes Castlemaine XXXX lager. That contract is still thriving 27 years later. In February TNT made its first foray into British brewery distribution when the company took over the distribution of Boddingtons' beers.

"When we announced the contract," says Paul Carvell, general manager of TNT Contract Services, "it was the first entire brewery distribution contract placed in this country. The National Freight Consortium's contract with Whitbread in London was a partnership."

BREWERY DIVISION

TNT won the Boddington's contract nine months after establishing a brewery division under Alvarez, a former Watneys man with 25 years in the business. "During that nine months we were putting proposals to potential customers," he says. "In brewing it can be difficult trying to persuade people to change. Contract distribution is not familiar except in the take-home market. Beer delivery is different. . . it's very specialised and we needed to convince the contractor we were capable of doing the work. That's partly the reason why we established a separate division for brewery distribution.

"The beer market has declined and it is getting more highly competitive," he adds. "For brewers the requirement is to maintain or increase their market share, which can require a lot of investment in marketing. It is possible, through contracting out, to release capital for marketing, including the production of fashionable premium beer in modern bottling lines.

"Another reason why some breweries are considering contracting distribution is the traditional working practice for draymen in the industry of "job and finish". It is an encouragement to get home quickly, so customer care is not as good as it could be. The breweries recognise that now. Job and finish had a very good use when it was first introduced, but now there are some problems," says Alvarez. "With TNT our draymen work a 39hour week plus overtime and the work is issued by the management. In some other businesses drivers can be back home by 2pm, when TNT can get several extra trips. We are not bound by restrictive practices. We have a totally clean sheet with no restrictions bar the law, drivers hours and the trade itself where we deliver at agreed times," There are 103 employees working on the Boddingtons contract, including 52 draymen. "Its a mix of TNT and former Boddingtons staff," says Carvell. "We interviewed all the people who wanted to be interviewed. There was a fairly smooth transition period, though there were some redundancies but our experience did help in various ways. TNT has never had a stop-page in 10 years."

Work on the contract started on 19 February and followed a strike at Boddingtons. "Many customers were suffering from the effects of the strike, so for the first two weeks demand was at Christmas levels," says Alvarez. "We knew exactly what was happening through our computer system and driver reports, and Boddingtons were informed of problems immediately. We all worked very long hours in the first two weeks, but none of the outlets went without beer."

TNT has invested £7 million in the Boddingtons contract, some of which was used to develop a computer system especially for the contract: "The computer controls the stock and assets for the customer, Orders are taken on it and fed into both TNT's and Boddingtons' computers, so Boddingtons can interrogate the distribution system without contacting TNT," says Alvarez. "It also schedules vehicle loading and deliveries and can even identify mistake makers through patterns.

"We debrief every driver at the end of the day to pick up any points — for example, if he has seen a competitor making a delivery. That could be useful information to our customers (Soddingtons in this case).

"We are setting service parameters to meet customer requirements," says Carvell, "and there are also self-imposed TNT standards. Boddingtons are probably getting more information about their distribution than they had before they went out to contract."

As part of the Boddingtons contract TNT has established a 5,800m2 (60,000ft2) warehouse in Wigan. The new warehouse, which opens officially on 9 June, takes products from Boddingtons' Strangeways brewery in Manchester and Higsons brewery in Liverpool, together with products such as Guinness from outside suppliers. Boddingtons' Oldham brewery was dosed at the start of the contract.

"We chose Wigan because it was there," says Alvarez. "The chances of finding somewhere with exactly the right warehouse placing are slim. It is big enough for expansion and there is room for support services like vehicle washing, maintenance and sales support."

The warehouse is staffed entirely by TNT personnel, but the stock is owned by Boddingtons and it is the brewery which determines stock levels. TNT designed the warehouse for easy handling of large numbers of different products. Several lines of angled roller conveyors, supplied by Planned Storage Systems of Swindon, continually move the products forward to the loaders, who load directly into waiting trailers.

FEW BREAKAGES

Six fork lift trucks fitted with Rodman beer clamps are used for palletless handling of beer kegs. No tanks are used on the contract — the largest container used is a 36 gallon (1641it) barrel.

"The stock is well controlled and losses are remarkably low with very few breakages," says Alvarez. "Breweries tend to allow people to drink at work, but TNT does not allow drink at all anywhere worldwide. Our ability to control the stock must be easier as a consequence."

"TNT designed the warehouse from scratch. Traditionally breweries have used premises built for the horse and cart 200 years ago," says Carvell. "We have had a lot of interest from breweries looking to set up lager production plants who want to see modern beer distribution methods."

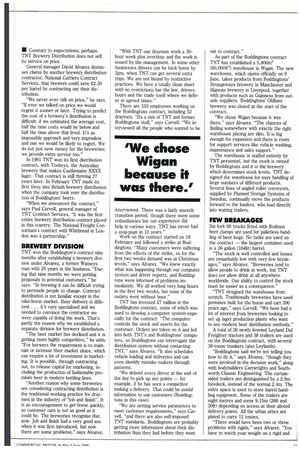

A total of 26 newly liveried Leyland Daf Freighter tractors and 38 trailers are used on the Boddingtons contract, with several 38-tonne trunkers (also Leylands).

"Boddingtons said we're not telling you how to do it," says Alvarez, "though they were involved in the decision work," along with bodybuilders Cartwrights and Southworth Chassis Engineering. The curtainsided trailers are distinguished by a 2.9m foredeck, instead of the normal 2.4m. The extra space is used to store barrel handling equipment. Some of the trailers are eight metres and some 9.15m (26ft and 30ft) depending on access at their alloted delivery points. All the urban artics are plated to carry 12 tonnes, "There would have been two or three problems with rigids," says Alvarez. "You have to watch your weight on a rigid and there is a high volume per drop rate in brewery distribution. With the urban artic we can get more on. They're more manoeuvrable, and by using trailers we can load a second trailer and hitch it up when the tractor returns."

Alvarez is confident that TNT can meet peaks in demand for beer with its dedicated Boddingtons fleet.

"The fleet size is fixed at a fairly high level," he explains. "The number of vehicles you need depends upon the number of drops you do, which is fairly constant at over 1,000. We currently work five days a week, no Saturdays except on Bank Holiday weekends. That builds in some spare capacity. We wouldn't bring in other companies to do the work, apart from trunking," says Alvarez.

Two draymen work on each urban artic. Boddingtons had three men on some runs but the company has since withdrawn its 54-gallon (2451it) hogshead, so there is less need for three.

Alvarez is keen to dispel suggestions that contractors are less careful about safety standards than the breweries themselves. "As far as we're concerned, our standards of safety are second to none. We have a winch on every vehicle which cuts out the really heavy stuff, and we give our staff a very thorough training using ropes and so on.

"Breweries are not bad in the safety league — there are lots of squashed fingers in the statistics. We are very determined to ensure there are no problems. All our staff had two weeks training — we built a mock cellar in another warehouse near Wigan."

TNT Brewery Distribution is now split into two parts. The operations side is based at Wigan under the control of general manager Ron Keefe, while sales and marketing are based in Bristol under Alvarez's control. "We have split the operation in two sides so we don't divert ourselves in the business of getting on," says Alvarez.

OTHER BREWERIES

Carvell and Alvarez are confident that other breweries will follow Boddingtons' lead: "We are very close to a large number of breweries and we are talking to a lot of people," says Alvarez.

"There will be a number of announcements in the next few months. The Boddingtons contract has awakened the interest of the industry. Lots of small breweries have problems in delivering their products to a wider market, we can help them spread their wings."

Boddingtons is very happy with the way the contract has gone so far. Assistant managing director Neil Kerr says: "TNT is already delivering the promise we hoped would be fulfilled — they have very much enhanced the level of customer service and efficiency."

Kerr admits that placing the company's distribution with a contractor was something of a gamble, especially because it was TNT's first brewery distribution contract in the UK. "They promised service and efficiency and their reputation in the distribution industry outside brewing was phenomenal," he says. "It was their first contract, but it came at a time when we were re-organising our production and warehousing round a new distribution centre, so it was an ideal time to go to contract."

Boddingtons has been keen to retain its name on the newly liveried distribution fleet and on the uniforms of the TNT Brewery Distribution draymen, to strengthen the link between the brewery and its customers in the licensed trade.

Kerr says: "We branded the distribution service as Brewerylink. Our trade customers want it to be seen as an extension of the brewery. There is no mention of TNT on the vehicles but our customers are very happy with the TNT link."

by Richard Scrase