HINTS ON MAINTENANCE.

Page 28

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble.

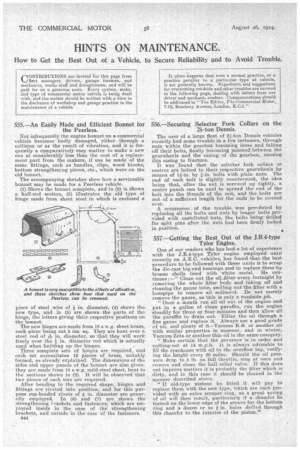

555.—An Easily Made and Efficient Bonnet for the Peerless.

Not infrequently the engine bonnet on a commercial vehicle becomes badly damaged, either. through a collision or as the result of vibration, and it is frequently a comparatively easy matter to make a new one at considerably less than the cost of a replacement part from the makers, if use be made of the same fittings, such as handles, clips, wood blocks, bottom strengthening pieces, etc., which were on the old bonnet.

The accompanying sketches show how a serviceable bonnet may be made for a Peerless vehicle. (1) Shows the bonnet complete, and in (2) is shown a half-end section, (3) illustrates the old type of hinge made from sheet steel in which is enclosed a piece of steel wire of in. diameter, (4) shows the new type, and in (5) are shown the parts of the hinge the letters giving their respective positions on the bonnet.

The new hinges are made from 18 s.w.g. sheet brass, each piece being cut 3 ins. sq. They are bent over a steel rod of -5-4-i in. diameter, so that they will work freely over the in. diameter rod which is actually used when building up the hinges. Three complete sets of hinges are required, and each set necessitates 12 pieces of brass, suitably formed, as already explained. The dimensions of the sides and upper panels of the bonnet are also given. they are made from 18 s.w.g. mild-steel sheet, bent to the sections shown in (2). It will ha observed that two pieces of each size are required. After bending to the required shape, hinges and fittings are riveted into position, and for this purpose cup-headed rivets of * in. diameter are generally employed. In (6) and (7) are shown the strengthening f--rackets and fasteners, which are employed inside in the case of the strengthening brackets, and outside in the case of the fasteners.

1344

556.—Securing Selector Fork Collars on the 21--ton Dennis.

The user of a large fleet of 2-ton Dennis vehicles recently had some trouble in a few instances, through nuts within the gearbox becoming loose and falling off their bolts, finally becoming jammed _between the gearwheels and the casing of the gearbox, causing this casing to fracture. It was found that the selector fork collars or centres are bolted to their respective gearwheels by means of by bolts with plain nuts. The end of each bolt is slightly countersunk, the idea being that, after the nut is screwed up tightly, a centre punch can be used to spread the end of the bolt into the threads of the nut, and the bolts are not of a sufficient length for the ends to be riveted over.

A recurrence of the trouble was prev6nted by replacing all the bolts and nuts by longer bolts provided with castellated nuts, the bolts beingdrilled for split pins after the nuts had been firmly locked

in position.

557.—Getting the Best Out of the J.B.4-type • Tylor Engine.

• One of our readers who has hada lot of experience with the J.B.4-type Tylor engine employed until recently on A.E.C. vehicles, has found that the best procedure to be followed with these units is to scrap the die-cast big-end bearings and to replace them by bronze shells lined with white metal. He continues :—" Clean out the oil–filter every fortnight by removing the whole filter body and taking off and cleaning the gauze tube, swilling out the filter with a hosepipe to remove all sediment. Do not merely remove the gauze, as this is only a roadside job. "Once a month run all oil out of the engine and put in a gallon of clean paraffin, run the engine steadily for three or four minutes and then allow all the paraffin to drain out. Filter the oil through a fine gauze and replace it. Always use a good grade of oil, and plenty of it—Vacuum B.B. or another oil with similar properties in summer, and in winter, Vacuum Zeta or another thin oil in the same category.

" Make certain that the governor is in order and

cutting-out at 14 m.p.h. It is always advisable to fill the crankcase with oil to the overflow tap, verifying the height every 20 miles. Should the oil pressure drop to 5 lb. on full throttle, stop at once and remove and clean the ball relief valve. If this does not improve matters it is probably the filter which is dirty, and in this case it should be cleaned in the manner described above,

" If old-type pistons be fitted it will pay to replace them with the new type, which are each provided with an extra scraper ring, as a great saving of oil will then result, particularly if a chamfer be turned on the lower edge of the groove for the bottom ring and a dozen or so in. holes drilled through this chamfer to the interior of the piston."