COOLING THE ENGINE BY EVAPORATION.

Page 68

If you've noticed an error in this article please click here to report it so we can fix it.

Specifications. A Resume of Recently Published Patent

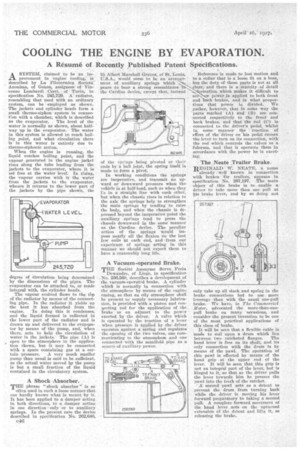

ASYSTEM, claimed to be an improvement in engine cooling, is described by La Filotermica Societit" Anonima, of Genoa, assignees of Vincenzo Lombardi Cerri, of Turin, in sPecifieation No. 245,729. A radiator, resembling that used with an ordinary system, can be employed as shown. The jackets and cylinder heads form a small thermo-siphon system in connection with a chamber, -whicb is described as the evaporator. The level of the water is normally as shown, about halfway up in the evaporator. The water in this system is allowed to reach boiling point, and what circulation there is in this water is entirely due to thermo-siphonic action.

When the engine is running, the liquid reaches boiling point, and the vapour generated in the engine jacket rises along the tube leading from the jackets to the evaporator, where it is set free at the water level: In rising, the vapour carries with it the water from the jackets to the evaporator, whence it returns to the lower part of the jackets by the pipe shown, the degree of circulation being determined by the dimensions of the pipes. The evaporator can be attached to, or made integral with, the cylinder heads.

The vapour evolved flows to the dip of the radiator by means of the connecting pipe.. In the radiator it yields up the heat it has absorbed from the engine. In doing this it condenses, and the liquid formed is collected in the lower part of the radiator and is drawn up and delivered to the evaporator by means of the pump, and, when there, acts to help the circulation of water in the jackets. The pipe (A) is open to the atmosphere in the application shown, but it may be connected with a space containing gas at a cer tain pressure. A very much smaller pump than usual is said to be sufficient, as the actual water moved by the pump is but a small fraction of the liquid contained in the circulatory system.

A Shock Absorber.

THE phrase "shock absorber" is so

often used in such a loose manner that one hardly knows what is meant by it. It has been applied to a damper acting in both directions, to a damper acting in one direction only or to auxiliary springs. In the present ease the device described in specification No. 262,646,

Wy Albert Marshall Graves, of St. Louis, U.S.A., would seem to be an arrangement of auxiliary springs which -1'4ptars to bear a strong resemblance to the Cardine device, except that, instead

of the springs being pivoted at •thei • ends by a ball joint, the spring itself is made to form a pivot.

In working conditions the springs are inoperative, and transmit no upward or downward pressure when the vehicle is at half-load, such as when they lie in a straight line with each other, but when the chassis rises in relation to the axle the springs help to strengthen the main springs by tending to raise the body, and when the chassis is depressed beyond the inoperative point the auxiliary springs tend to press the chassis downward in the same manner as the Cardine device. The peculiar action of the springs would impose nearly all the flexion on the last few coils at each end, and from our experience of springs acting in this manner we should not expect them to have a reasonably long life.

A Vacuum-operated Brake.

THE Sociote Anonymc Servo Prein

Dexvandre, of Liege, in specification , No. 256,560, describes a development of the vacuum-operated brake. A cylinder which is normally in connection with the atmosphere by means of the engine casing, so that an oily atmosphere shall be -present to supply necessary lubrication, is provided with a piston and connecting rod for the applicationof the brake as an adjunct to the power exerted by the driver. A valve which is operated by the reaction of a lever when pressure is applied by the driver operates against a spring and regulates the opening of the two valves, one communicating to the atmosphere and one connected with the manifold pipe as a source of auxiliary power. Reference is made to Jost motion and to a collar that is a loose fit on a boss, but the duty of these parts is not at all clear, and there is a -scarcity of detail ,.-formation which makes it difficult to see :--eys power is applied to both front and back brakes, and in what propor tions that power. is divided. We gather, however, that in some way the partsmarked (A) and(B) are connected respectively to the front and hack brakes, • and that the rod (C) is connected to the driver's pedal, whilst in some manner the reaction of effort of the driver on his pedal causes the lever to turn on its connection, with the rod which controls the valves as a fulcrum, and that it operates them in accordance with the power he is exerting.

The Neate Trailer Brake.

REGINALD W. NEATE, a name already well known in connection with brakes 'fOr trailers, appears in specification No. 267,197. The main object of this brake is to enable a driver to take more than one pull at his brake lever, and by so doing not only take up all slack and spring in the brake connections but to use more leveraga than with the usual one-pull brake. We have, in The Commercial Motor, advocated the more-than-onepull brake on many occasions, and consider the present invention to be one of the most practical applications of this class of brake.

It will be seen that a flexible cable is made to coil upon a drum which lies between two ratcheted flanees. The hand lever is free on its shaft, and its only connection with the drum is by means of the pawl. The operation of this pawl is effected by means of the hand grip at the upper end of the lever. It will be seen that. this grip is not an integral part of the lever, but is hinged to it, so that as the driver pulls the lever towards him he presses the pawl into the teeth of the ratchet.

' A second pawl acts as a detent to prevent the drum from turning back while the driver is moving his lever forward preparatory' to taking a second pull. A complete forward movement of the hand lever acts on the upturned extension of the cletent and lifts it, so releasing the brake.