WAYS AND MEANS.

Page 67

If you've noticed an error in this article please click here to report it so we can fix it.

Useful Contributions from Our Driver and Mechanic Readers.

Split-pinning When Drills Are Not Available.

rrIIIETIE are times when fitting new _L bolts to parts of motor vehicles that it is necessary to use a split-pin, or its equivalent, and sometimes no means for drilling the necessary hole for the pin is at hand. In some instances a castle or slotted nut even is not available, yet a nut has to be securely fastened to its bolt.

Various methods, sum as burring over the end of the bolt, have been used, but. hammering on the end of a bolt is likely to have the effect of loosening it, and when the time comes that a more permanent repair has to be effected there is usually a good deal of trouble ahead of anyone who has to remove a bolt that has been burred over.

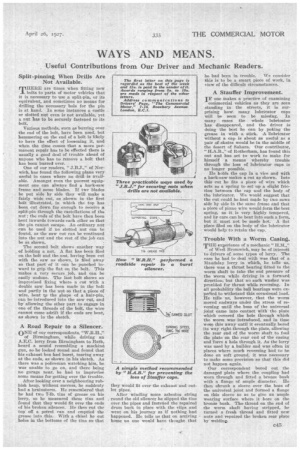

One of our readers, " I.B.I.," of Norwich, has found the following plans very useful in cases where no drill is available. Amongst even the poorest equipment one can always find a hack-saw frame and some blades. If twe blades be put side by side they will make a fairly wide cut, as hown in the first bolt illustrated, in which the top has been cut down far enough to receive a split-pin through the castellations of the. nut ; the ends of the bolt have then been bent inwards towards each other so that the pin cannot escape. An ordinary nut can be used if no slotted nut can be found, as the saw cut can be continued into the nut and the rest of the job can be as shown.

The second bolt shows another way of holding a nut. A flat has been filed on the bolt and the nut, having been cut with the saw as shown, is filed away so that part of it can be punched inward to grip the flat on the bolt. This makes a very secure job, and can be easily undone. The last bolt shows an improvised fixing where a cut with a double saw has been made in the bolt and partly in the nut so that a piece of wire, bent to the shape of a hair-pin, can be introduced into the saw cut, and by allowing the other part to engage in one of the threads of the bolt, the wire cannot come adrift if the ends are bent, as shown in the sketch.

A Road Repair to a Silencer.

ONE of our correspondents, "W.R.H.," of Birmingham, while driving an A.E.C. lorry from Birmingham to Bath, heard a sound resembling a machind gun, so he looked round and found that his exhaust box had burst, tearing away at the ends, as shown in his sketch. As there was a policeman watching him, he was unable to go on, and there being no garage near, he had to improvise some means for getting over the trouble. After looking over a neighbouring rubbish heap, without success, he suddenly had a brainstorm. He remembered that he had two 7-lb. tins of grease on his lorry, so he measured these tins and found that they would fit over the ends of his broken silencer. He then cut the top off a petrol can and emptied the grease into this. With a chisel he cut holes in the bottoms of the tins so that they would fit over the exhaust and outlet After winding some asbestos string . round the old silencer he slipped the tins over the pipes and fastened the repaired drum back in place with the clips and went on his journey as if nothing had happened. He tells us that on arriving home no one would have thought that he had been in trouble. We consider this is to be a smart piece of work-, in view of the difficult circumstances.

A Stauffer Improvement.

IF one makes a practice of examining conimercial vehicles as they are seen standing in the streets, it is surprising how'. many lubricator caps will be seen to be missing. In many cases the whole lubricator has disappeared, and the driver is doing the best he can by poking the grease in with a stick. A dubricator without a cap is about as useful as a pair of skates would be in the middle of the desert of Sahara. Our contributor, of Rotherham, has fonnd this out and has set to work to make for himself a means *hereby trouble through the loss of lubricator caps is no longer possible. He holds the cap in a vice and with a hack-saw makes a cut as shown. Into this cut he fits a piece of wire which acts as a spring to set up a slight friction between the cap and the body of the lubricator. We would suggest that the cut could be best made by two saws side by side in the same frame and that a piece of piano wire would form the best spring, as it. is very highly tempered, and by care can be bent into such a form, but it must not be mole hot. A fiat place filed on the body of the lubricator would help to retain the cap.

Trouble With a Worm Casing.

THE experience of a mechanic "HAL,"

of Weat Bromwich, may be of interest to drivers of some typea of lorry. The case he had to deal with was that of a Ala-mislay lorry in which, he tell us, there was a thrust bearing fitted to the worm shaft to take the end pressure of the worm while driving in a forward direction, but that no such washer was provided for thrust while reversing. In all probability the ball bearings were expefted to withstand this occasional load. He tells us, however, that the worm moved endways under the stress of reversing until the boss of the universal joint came into contact with the plate which covered the hole through which the worm was introduced, and in time wore this away until it eventually bored its way right through the plate, allowing the rear end of the worm shaft to foul the plate on the rear end of the casing and force a hole through it. As the lorry was used by a builder and was often in places where much reversing had to be done on soft ground, it was necessary to make Some provision so that this did not happen again.

Our correspondent bored out the damaged plate where the coupling had worn through and fitted a bronze bush with a flange of ample diameter. He then shrunk a sleeve over the boss of the universal joint and formed a flange on this sleeve Co as to give an ample wearing surface where it bare on the bronze bush. Thn thread on the end of the worm shaft having stripped, be turned a fresh thread and fitted new nuts and repaired the broken rear plate by welding.