From the Drawing Boar

Page 64

Page 65

If you've noticed an error in this article please click here to report it so we can fix it.

by Graham Montgomerie

Testing methods have improved by leaps and bounds during recent years. Esso'l dynamometer complex at Abingdon, for instance, cost 0.8m and allows testing up to 140mph on rolling roads and at Saharan to Arctic temperatures

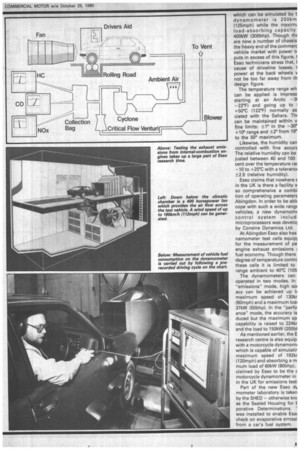

E TECHNIQUES for deoping products for the auto)tive industry have pro!ssed in leaps and bounds in ent years. It is not just the 1-products which have been proved; the methods of ting them have received just much technological expertise. s applies to all products — be chassis, a gearbox or, as in ; case, a petroleum product. artier this year Esso opened a lamometer laboratory cornx at a cost to the company of Brn. Situated at the Esso Peleum Research Centre at ngdon, Oxfordshire, the new lilies will permit the Esso mtists to run vehicles from torcycles to heavy lorries on ing roads that can deal with eds up to 225km/h (140mph), lynamorneter test cells for icles have a number of adtages for the development iineer. It is possible to imve the accuracy of the experirital results by controlling the temperature, humidity and road conditions.

eing thus independent of the ither, it makes it easy for o to repeat any part of a partiar test if necessary and imises delays in testing due )reakdowns.

any delays do happen for itever reason, it is possible to :h up on the test programme working 24 hours a day. Obisly, this isn't impossible on 1 test but it can be extremely cult.

Jch testing is normally the -ogative of the chassis manuurers so what does Esso get of it?

;so needs to know what

of fuels and lubricants to .ket to satisfy the European licle population on such is as cold start, knock and our lock.

the Eighties world of the ironment and economy, ) also needs to know the et of its fuels and lubricants !missions and fuel economy. ; far as the cold-start probis concerned, Esso has to le the fuel volatility and ze point (for diesels) and the icant viscosity needed. For petrol engine, what octane iber stops pinking and en! damage? And so on.

) enable Esso to do all this work using modern technology, the new laboratory incorporates a climatic chamber. As the name suggests this room can be used to test the relevant Esso products in a realistic manner over the full range of temperature and humidity conditions to which they are exposed.

A vehicle on test in the climatic chamber is positioned on the dynamometer rollers at ground level. Down below in the basement is a 400 horsepower fan which provides an air flow across the vehicle equivalent to that associated with a specific speed on the road. The air flow is recycled through the floor into the basement which also contains a heat exchanger for temperature control.

The fan is continuously variable to provide the correct wind simulation over the vehicle speed range up to a maximum of 180km/h (112mph).

The dynamometer assembly is geared to accept anything from the smallest private car to a top-weight tractive unit. It can also cater for fwd vehicles.

The maximum road speed which can be simulated by t dynamometer is 200km (125mph) while the maximc load-absorbing capacity 400kW (300bhp). Though the are now a number of chassis the heavy end of the commerc vehicle market with power o puts in excess of this figure, t Esso technicians stress that, cause of driveline losses, 1 power at the back wheels v not be too far away from th design figure.

The temperature range wh can be applied is impress starting at an Arctic —31 —22°F) and going up to 1 +50°C (122°F) normally as ciated with the Sahara. ThE can be maintained within v fine limits: ±1° in the —30° +10° range and ±2° from 19° to the 50° maximum.

Likewise, the humidity can controlled with fine accurE The relative humidity can be justed between 40 and 100 cent over the temperature rat —10 to +25°C with a toleranct ±2.5 (relative humidity).

Esso claims that nowhere E in the UK is there a facility v so comprehensive a combi tion of operating parameters Abingdon. In order to be abit cope with such a wide range vehicles, a new dynamomt control system includl microprocessors was develol by Consine Dynamics Ltd.

At Abingdon Esso also has namometer test cells equip' for the measurement of pe engine exhaust emissions fuel economy. Though there degree of temperature contrc these cells it is limited to range ambient to 40°C (105 The dynamometers can operated in two modes. In "emissions" mode, high act acy can be achieved up tt maximum speed of 130kr (80mph) and a maximum low 37kW (50bhp). In the "perfo ance" mode, the accuracy is duced but the maximum sp capability is raised to 224kr and the load to 150kW (200b1 As mentioned earlier, the E research centre is also equip with a motorcycle dynamorni which is capable of simulatir maximum speed of 192kr (120mph) and absorbing a m mum load of 60kW (80bhp). claimed by Esso to be the c motorcycle dynamometer in in the UK for emissions test Part of the new Esso dy mometer laboratory is taken by the SHED — otherwise knc as the Sealed Housing for E porative Determinations. was installed to enable Essc check on evaporative emissi from a car's fuel system.