WAYS AND MEANS.

Page 75

If you've noticed an error in this article please click here to report it so we can fix it.

Useful Contributions From Our Driver and Mechanic Readers.

To Save the Leathers of Hydraulic Tipping Gears.

FROM Sandbach, Cheshire, "E.J." writes us as follows:— Quite frequently trouble is -experienced with the leather washer on the piston of hydraulic tipping gears. The Usual practice is to provide a release hole in the cylinder at a point where the piston should stop when the desired tipping angle is reached. This release hole should be made large enough in diameter or big enough in area to take the water or oil as fast as it is pumped into the t ylinder, thus forming a positive check on the piston lift, although the pump keeps working.

Trouble is often encountered when the piston is almost at the end of its stroke. As the leather passes the release hole referred to the pressure is so great (anything between 350 lb. and 500 lb. per sq. in., according to load) that it forces the leather, which is only

about in. thick, into the release hole; thus causing a bulge which in time damages the leather washer. Moreover, as the piston is mounted on a spherically ended. connecting rod it can turn round; thus the bulge may take place in a different position each time, with a badly leaking washer as a result.

As a simple remedy I suggest the following, which is a complete cure for the trouble. First tap out the existing release hole to i-in. gas thread, then . make a plug to screw into the release bole. This plug should be made long enough to be screwed for a union, so that the overflow pipe can be coupled to it.

The plug is then drilled down in. in diameter until the hole breaks into the two small .4-in. holes drilled at right angles to each other on the plain portion of the plug at the end.

The length of the plug should be regulated so that the plain end comes level with the inside of the cylinder wall. This, of course, forms a support for the leather washer. when the pressure is on it. After the washer has passed the release hole the water escapes through the, gap between the plug and the hole, then through the four small holes and away to the overflow pipe. This idea can be beneficially applied to most tipping gears and will quickly pay for itself in the saving of leather washers.

The Proper Use of the Clutch.

THAT trouble with clutches is invari ably caused by improper use of that very important unit is pointed out by one of our correspondents, " II.F.W.," of Burton-on-Trent, who finds that many drivers of vehicles with fourspeed gearboxes contract the habit of getting away on the second speed instead . of using the first. Having found that this is possible, they do not trouble to use the first, little thinking of the stress they are imposing on the clutches,

It is obvious, when one thinks it out, that the clutch should not be used in this way, as the starting torque required by a heavy lorry in the higher gears is more than any clutch can bear, consequently a good deal of slipping must occur', and it is this-slipping that ruins a clutch; whereas when the first gear is used for starting the clutch can take up its load without distress.

Another abuse to which he calls attention, and one that is common among inexperienced drivers, is to change to a higher gear while the vehicle has not got sufficient way on it to pick up without stressing the clutch, and this causes slipping to Jake place.

A further and still more serious abuse he mentions is.the delaying until the last moment of the change-down on hills when the lorry is almost at a standstill. The use of the clutch in traffic when slowing up, cornering, etc., is another matter to which he calls attention.

Truing Pitted Valves.

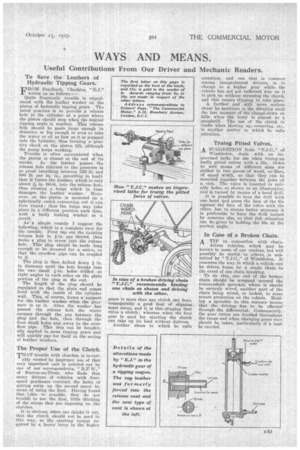

A STJGGESTION from "T.J.C.," of

Wimbledon, deals with an Improvised lathe for use when truing-up badly pitted valves with a file. Holes to suit stems of different sizes are drilled in two pieces of wood, or fibre, of equal width, so that they can be mounted together between the jaws of a vice. The valve is inserted in suitable holes, as shown in an illustration, and is turned by means of a hand drill.

It is possible to turn the drill with one hand and press the face of the file against the face of the valve with the other, but to ensure better accuracy it is preferable to have the drill turned by someone else, so that full attention can be given to holding the file at the corttct angle.

In Case of a Broken Chain.

A TIP in connection with chain

driven vehicles, which may be known to some of our readers, but will possibly be Useful to others, is submitted by " T.J.C.," of Wimbledon. It concerns the way in which a vehicle can be driven home by a single chain in the event of one chain breaking.

To do this, one end of the broken chain should be wrapped around the countershaft sprocket, where it should be securely wired, another part of the chain being wired, or lashed, to some secure projection on the vehicle. Holding a sprocket in this manner means that the driving has to be effected through the differential. Corsecluently.. the gear ratios are doubled throughout the range and when changing gears care should be taken, particularly, if a load be carried.