A NEW 6-TON STEAM TIPPING WAGON.

Page 51

Page 52

If you've noticed an error in this article please click here to report it so we can fix it.

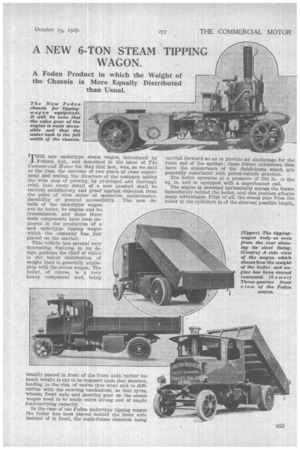

A Foden Product in which the Weight of the Chassis is More Equally Distributed than Usual.

911:1E new undertype steam wagon, introduced by

Fodens, Ltd., and described in the issue of The Commercial Motor for May 3Ist last, was, as we said at the time, the outcome of two years of close experiment and testing, the directors of the company taking the wise step of proving, by prolonged and thorough trial, that every detail of a new product shall be entirely satisfactory and proof against objection from the point of view either of operation, maintenance, durability or general accessibility. The new details of the undertype wagon are its boiler, its engine and its transmission, and these three main components have been employed in the production of a new undertype tipping wagon which the company has just placed on the market.

This vehicle has several very interesting features in its design, perhaps the chief of which is the better distribution of weight than is generally attainable with the steam wagon. The boiler, of course, is a very heavy compouent .and, being usually placed in front of the front axle, rather too much weight is apt to be imposed upon that member, leading to the risk of undue tyre wear and to difficulties with the steering mechanism, so that tyres, wheels, front axle and steering gear on the steam wagon need to be made extra strong and of ample load-carrying capacity. .

In the case of the Foden undertype tipping wagon the boiler has been placed behind the front axle instead of in front, the main-frame channels being carried forward so as to provide an anchorage for the front end of the springs; these frame extensions then have the appearance of the dumb-irons which are generally associated with petrol-vehicle practice.

The boiler operates at a pressure of 250 lb. to the sq. in. and is equipped with a superheater coil.

The engine is mounted horizontally across the frame immediately behind the boiler, and this position affords many advantages. First of all, the steam pipe from the boiler to the cylinders is of the shortest possible length, and this, of course, means that a considerable amount of condensation of the steam is avoided. Adjustments of any working parts of the engine are greatly facilitated by its position, as a mechanic is able to carry out the work without the need for getting down on to the floor beneath the chassis. The removal of a cover enables the valve gear to be examined, thus effecting a great saving in time and labour.

Immediately behind the side of the crankcase which is towards the rear of the vehicle the feed-water pump is carried, and immediately behind the pump is a water tank of 200-gallons capacity underslung from the chassis frame, this tank being U-shaped in order to allow the propeller shaft to pass from the gearcase to the rear axle.

The final drive is taken through a worm and worm wheel enclosed in the axle casing and, of course, running in an oil bath.

The substitution of propeller-shaft drive for chains permits the water tank to be made very wide and, besides slightly increasing its capacity, allows the weight to be better distributed.

It has been found in practice that for this type of vehicle a vertical steering shaft is most suitable, and the steering gear has been carried out in a very workmanlike manner, the gearing itself being made extremely accessible for attention or adjustment. This fact, and the accessibility of the valve gear of the engine, can clearly be seen from one of the illustrations which accompany this article.

, The tipping of the body is effected by a hydraulic tipping ram working in conjunction with a powerful steam pump fixed by the side of the boiler and worked by steam from •the latter. The hydraulic cylinder is carried by plates fixed to the main frame and it is positioned in the centre of the body, so that tipping all three ways may be adopted without involving undue strain upon the body. The hinges for tipping to the side are strong brackets securely fastened to the crosschannel members of the frame, the hinge pins being bolted to the channels permanently fixed to the chassis, whilst the sockets are bolted to the channels which form part of the body frame and move when the body is called upon to tip. By these means the body is carried clear of the wheels and any other projections, whilst at the same time it tips the material clear of the wheels. The end-tipping brackets are bolted to the rear cross-member of the main frame.

The body itself is lined with sheet steel and is of ample capacity, because it is 12 ft. long and 7 ft. wide, the height of the sides being 21 ins.

Tipping to the rear, an angle of 37 degrees is possible, and with a tip to the sides a slightly greater angle of 45 degrees can be reached.

The Foden tipping wagon is equipped on the rear axle, with twin rubber-tyred wheels of large diameter, whilst the cab LS a comfortable, roomy shelter, and the boiler. shrouding is shaped to give an excellent view forward for the driver,